A blank casting cavity pressure detection device

A detection device and pressure technology, which can be used in the application of stable tension/pressure to test the strength of materials, by measuring the acceleration and deceleration rates of fluids, and using liquid/vacuum for liquid tightness measurement. The force of the blank casting cannot be adapted to the detection device on the bottom surface of the blank casting, and the air tightness of the connection between the detection device and the casting cannot be guaranteed, so as to solve the problems of uneven extrusion and uniform connection force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

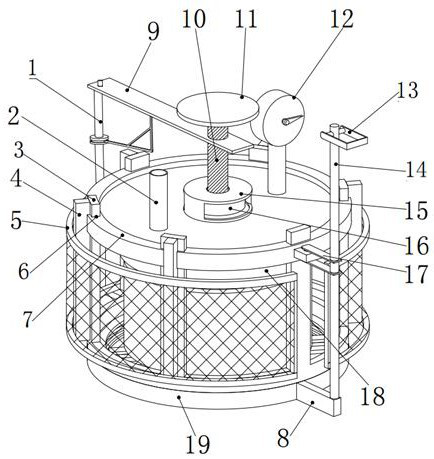

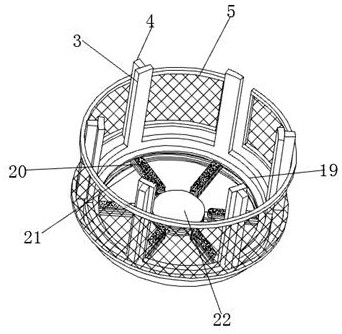

[0042] Such as Figure 1-Figure 9 As shown, a blank casting cavity pressure detection device includes a pressure detection cover 7, a rotating sleeve 15 is provided at the center of the upper surface of the pressure detection cover 7, and an inner rotor 16 is provided in the inner cavity of the rotating sleeve 15, The upper surface groove of the inner rotor 16 is internally threaded with a screw 10, and the upper end of the screw 10 passes through the through hole at the upper end of the rotating sleeve 15 and is threaded with a turntable 11, and the outer ring wall of the pressure detection cover 7 is wound around it. The center of the circle is provided with several guide grooves 6, and guide block bars 3 are slidably connected in the guide grooves 6, and the side walls of the guide block bars 3 are provided with side guide block bars 4 perpendicular thereto, the side guide block bars 4 The lower end is provided with a base bracket 19, the lower surface of the pressure detec...

Embodiment 2

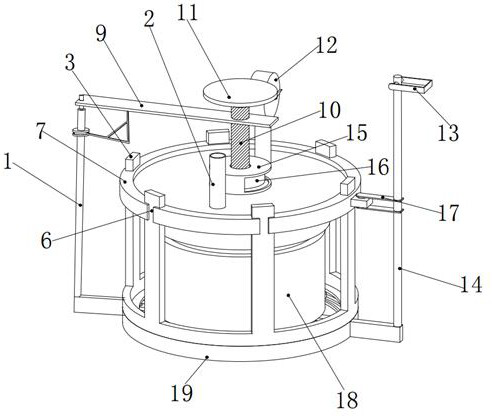

[0051] Based on the rough casting cavity pressure detection device provided in the first embodiment of the present application, the second embodiment of the present application proposes another rough casting cavity pressure detection device. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment. The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0052] Based on the first embodiment, the difference between the second embodiment and the first embodiment is that the second embodiment also has the following characteristics: refer to Figure 10 and Figure 11 As shown, the upper end of the screw 10 is threaded with a turntable 11. This knot makes the upper end of the screw 10 threaded with the turntable 11, while the lower end of the screw 10 is threaded wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com