Manufacturing process of photoelectric liquid level meter

A photoelectric liquid level gauge and manufacturing process technology, which is applied in the field of processing and manufacturing, can solve the problems of lens damage, affecting processing efficiency, and high control precision requirements, and achieve the effects of improving smoothness, uniform connection force, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 discloses a manufacturing process of a photoelectric liquid level gauge for the present invention, comprising the following steps:

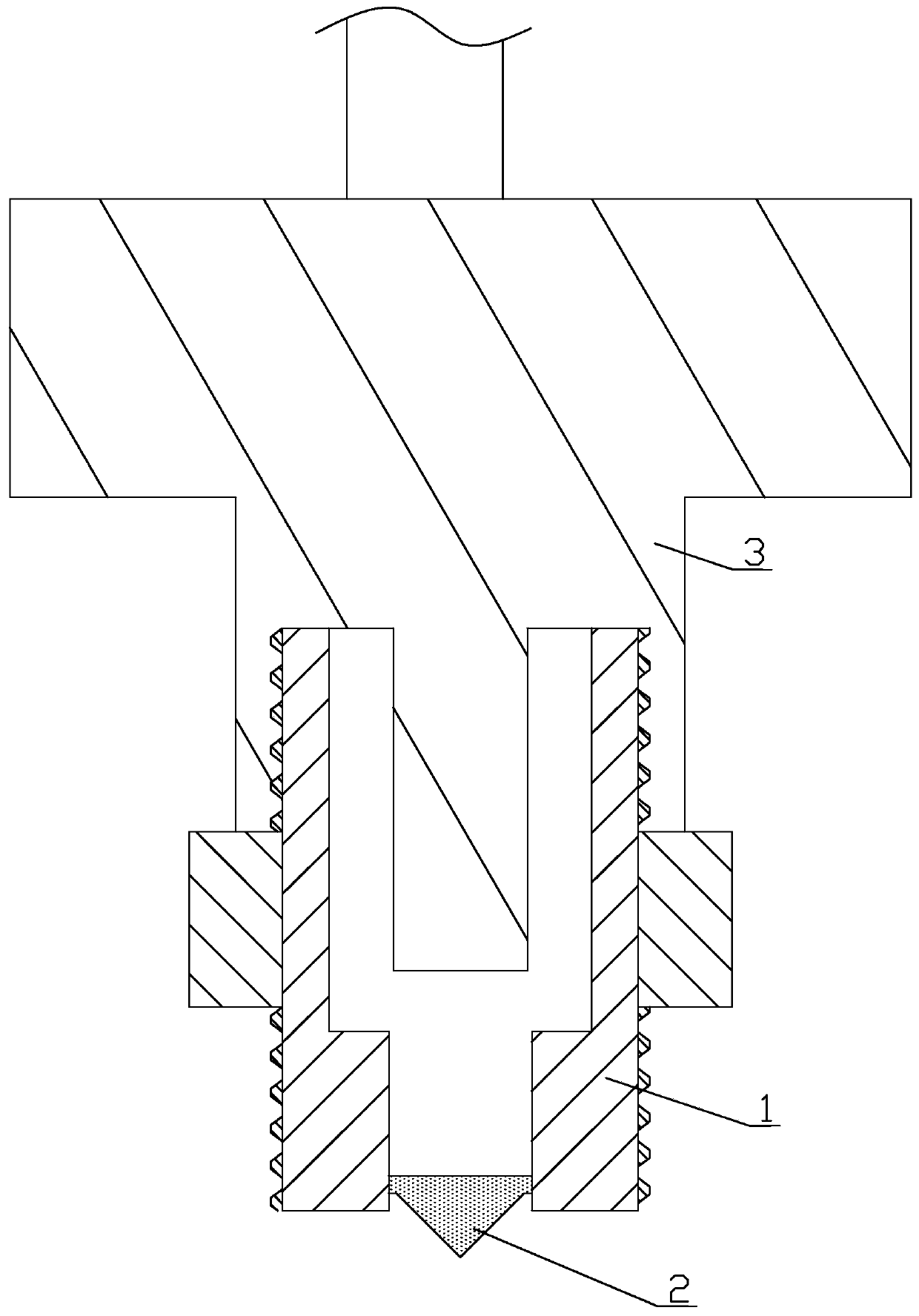

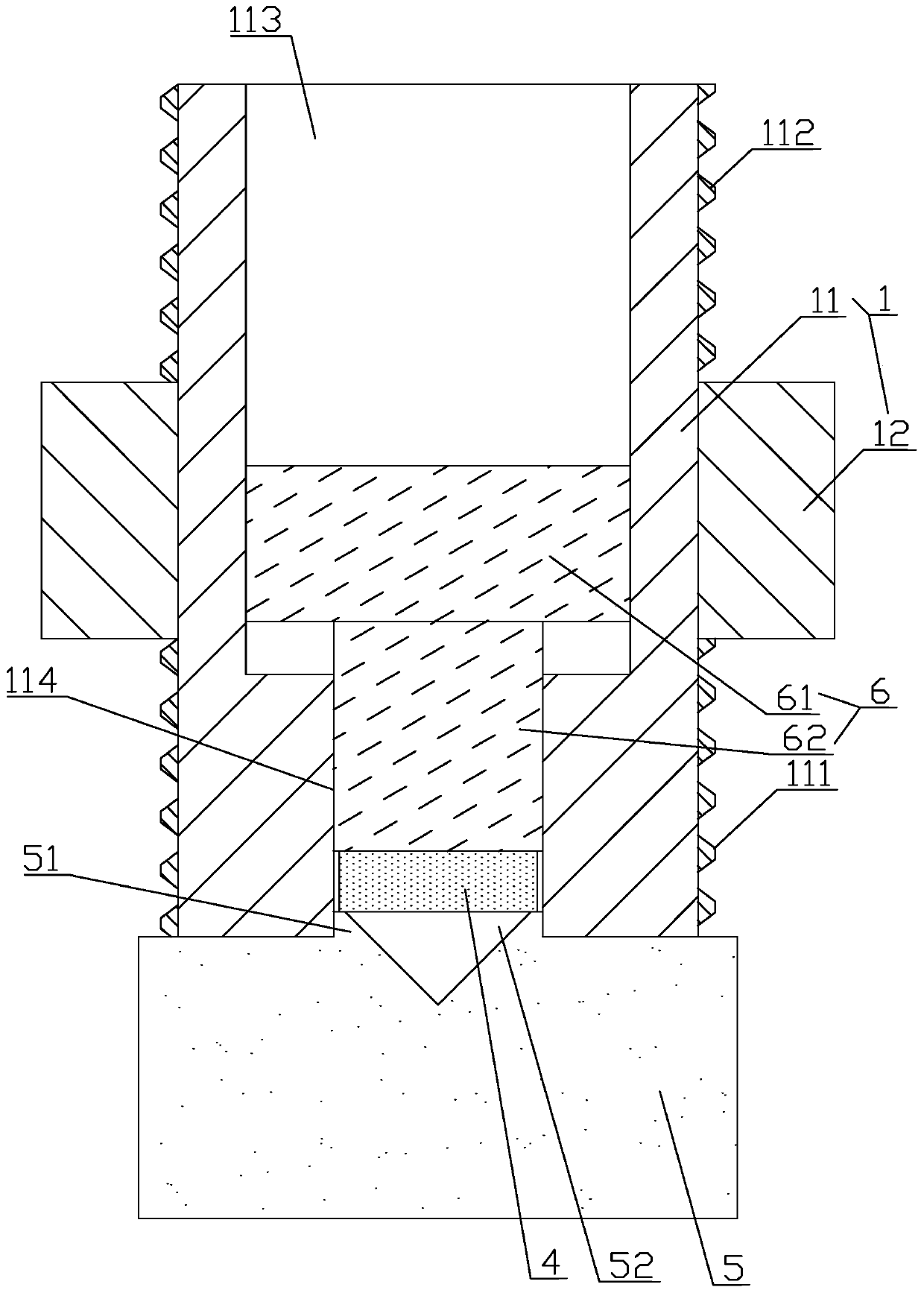

[0032]S1. Process the detection shell 1. Such as figure 2 As shown, the detection housing 1 includes a mounting tube 11 and a mounting nut 12. The mounting tube 11 is in the shape of a round tube with a vertical axis, and the mounting tube 11 is made of 20# steel. The mounting nut 12 is a hexagon head nut. The mounting nut 12 is sheathed on the mounting pipe 11 and fixed to the outer wall of the mounting pipe 11 . The mounting nut 12 is arranged in the middle of the mounting pipe 11 . An installation thread 111 and a fastening thread 112 are provided on the outer wall of the installation pipe 11 , and the installation thread 111 is provided on the lower side of the installation nut 12 for installing the photoelectric liquid level gauge. The fastening thread 112 is provided on the upper side of the mounting nut 12 for mounti...

Embodiment 2

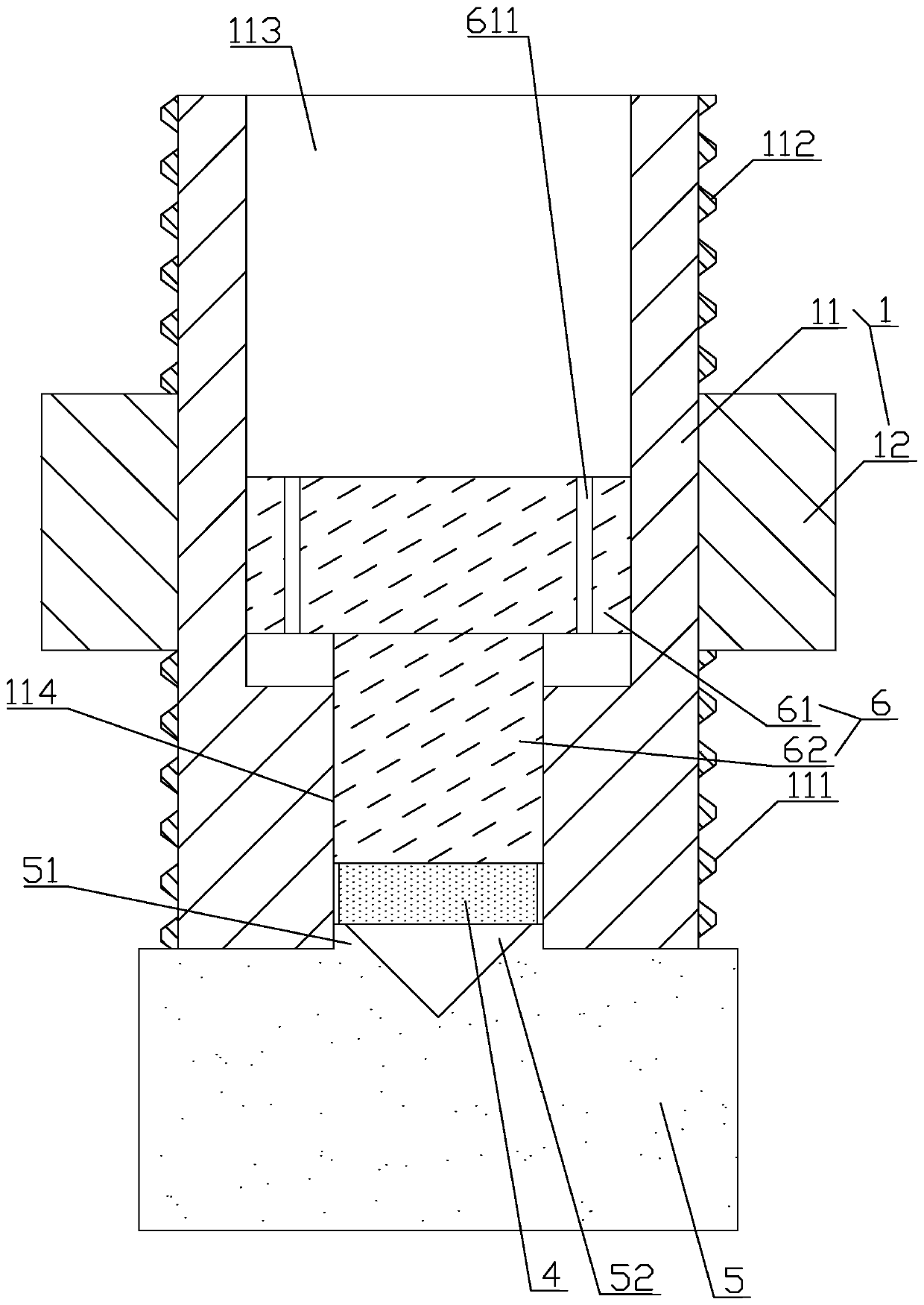

[0040] Embodiment 2 is the manufacturing process of another kind of photoelectric liquid level gauge disclosed by the present invention, such as image 3 As shown, compared with Embodiment 1, the difference of this embodiment is that the bottom surface of the gravity round block 6 is also provided with a ventilation microhole 611, the opening of the ventilation microhole 611 is circular, and the ventilation microhole 611 runs through the gravity round block 6 and is connected with the gravity round block 6. The upper surface of gravity round block 6 is connected.

[0041] In step S4, when the detection housing 1 is heated in the sintering furnace, the glass block 4 is heated and melted, and the gravity round block 61 drives the lower pressure column 62 to move down under the action of gravity. The air between the inner bottom surface of the groove 113 is discharged from the detection housing 1 through the ventilation microhole 611, thereby preventing this part of the air from ...

Embodiment 3

[0042] Embodiment 3 is the manufacturing process of another kind of photoelectric liquid level gauge disclosed by the present invention, such as Figure 4 As shown, compared with Embodiment 2, the difference of this embodiment is that a glass ring 612 is fixed on the bottom surface of the gravity circle block 6, and the glass ring 612 is a circular ring, which is sleeved on the lower pressure column 62, and the inner wall of the glass ring 612 and the lower The side wall of the pressure column 62 is attached, and the outer wall of the glass ring 612 is consistent with the outer diameter of the gravity circle 61 . In addition, the glass ring 612 is made of glass whose melting point is lower than the melting point of the material of the glass block 4 .

[0043] In step S4, when the detection housing 1 is heated in the sintering furnace, the glass block 4 is first heated and melted. At this time, the glass ring 612 has a supporting effect on the gravity circle block 61, and the gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com