Hole connecting device

A connecting device and a technology for holes, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of difficult and impossible connection of holes, and achieve the effects of convenient control, easy processing, and good guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

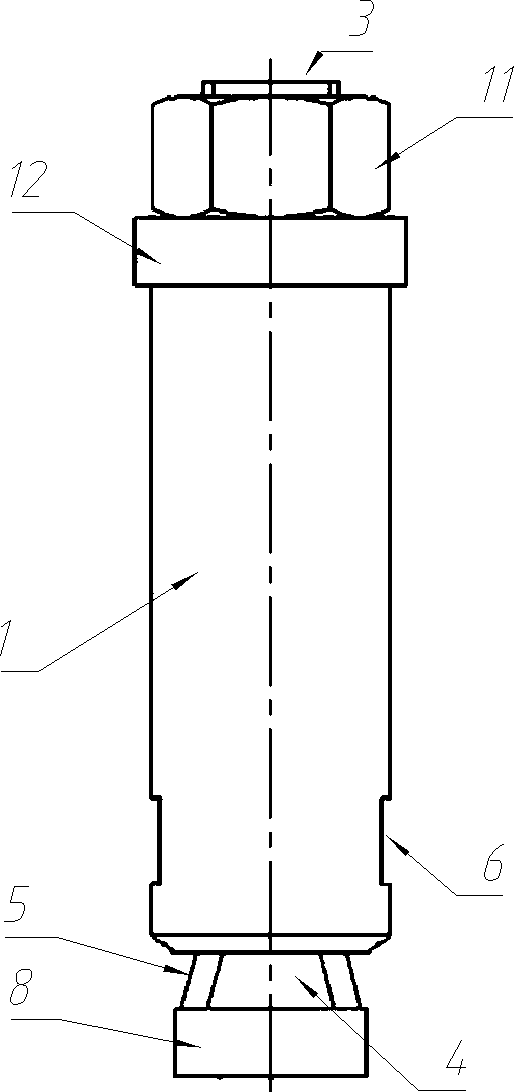

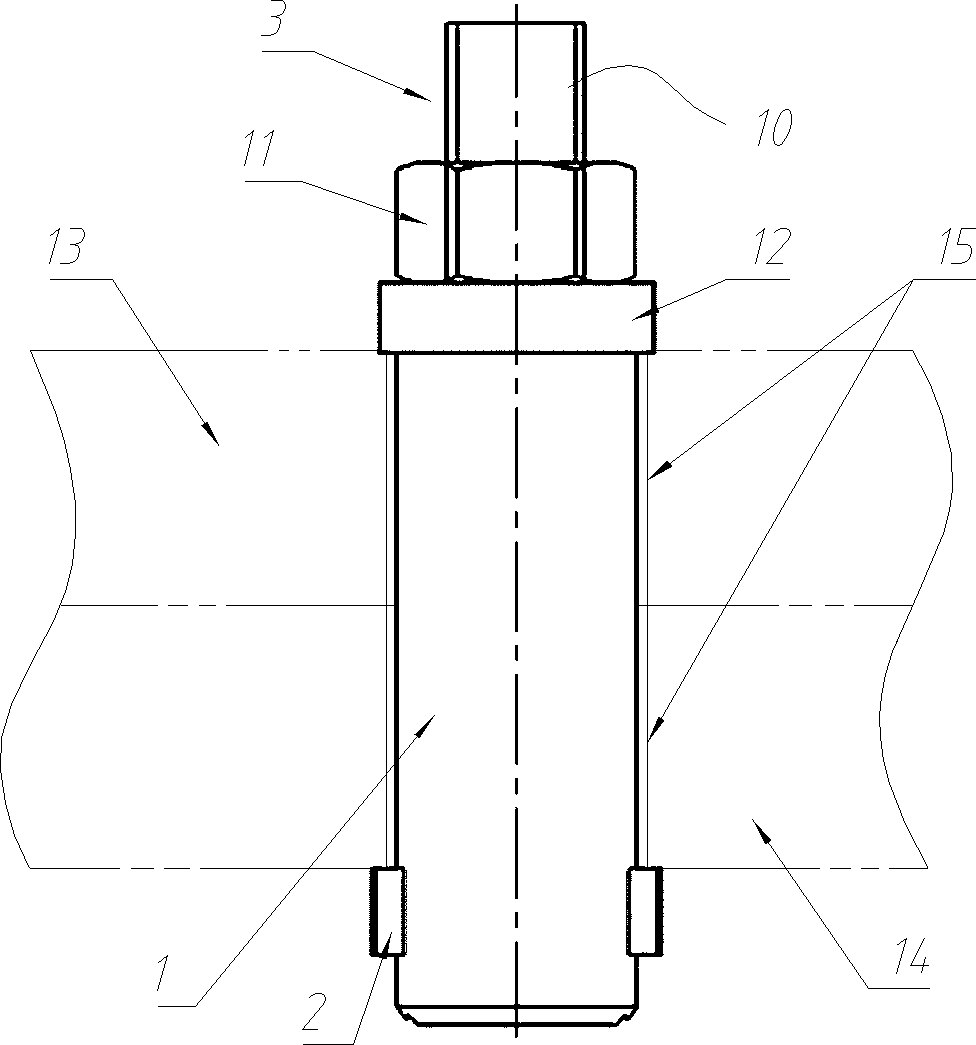

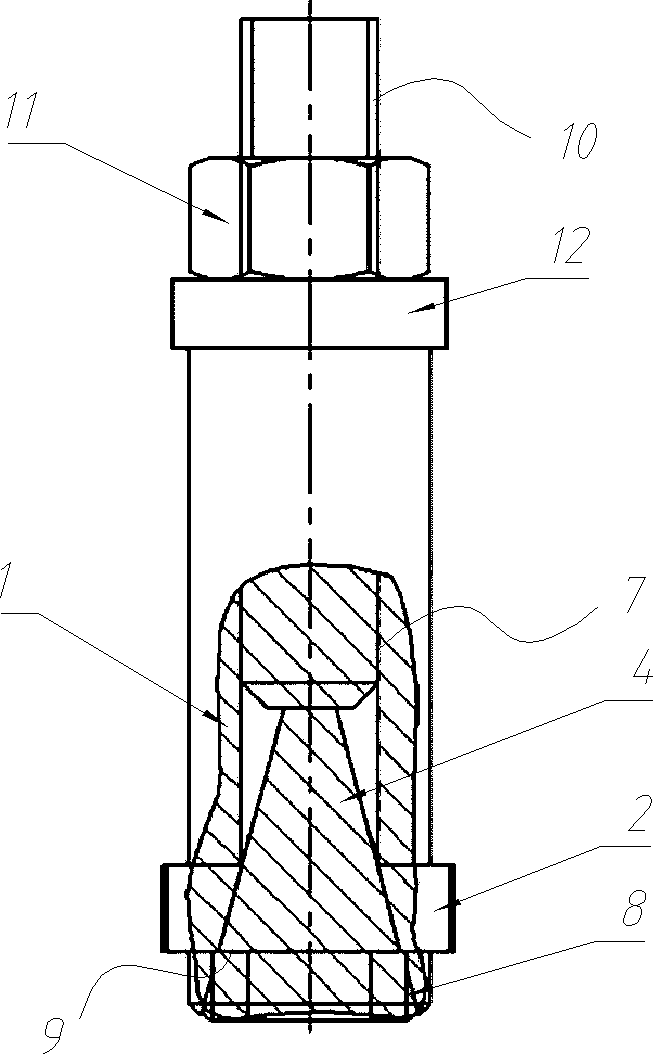

[0037] Embodiments of the hole connecting device of the present invention are as Figure 1~Figure 3 As shown, it is a hole connection device for large workpieces, including a connecting cylinder 1, a fastening rod 3 pierced into the connecting cylinder 1 from bottom to top, a stop ring 12 sleeved on the upper end of the fastening rod 3, A slide block 2 movably arranged along the radial direction of the connecting cylinder 1 and a lock nut 11 adapted to the threaded section 10 at the top of the fastening rod 3 .

[0038] The connecting cylinder 1 is a vertical through-hole structure, and its lower end is a plug-in end for inserting into the connected through-hole and positioning and matching with the through-hole in the radial direction. Square guide holes 6, each square guide hole 6 is respectively provided with a square slider 2, the inner end of the slider 2 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com