Locking device

A technology of locking device and locking part, which is applied in the direction of quick-action fasteners, etc., can solve the problems of potential safety hazards, tool movement up and down, affecting the processing effect, etc., and achieve the effect of improving the relative fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

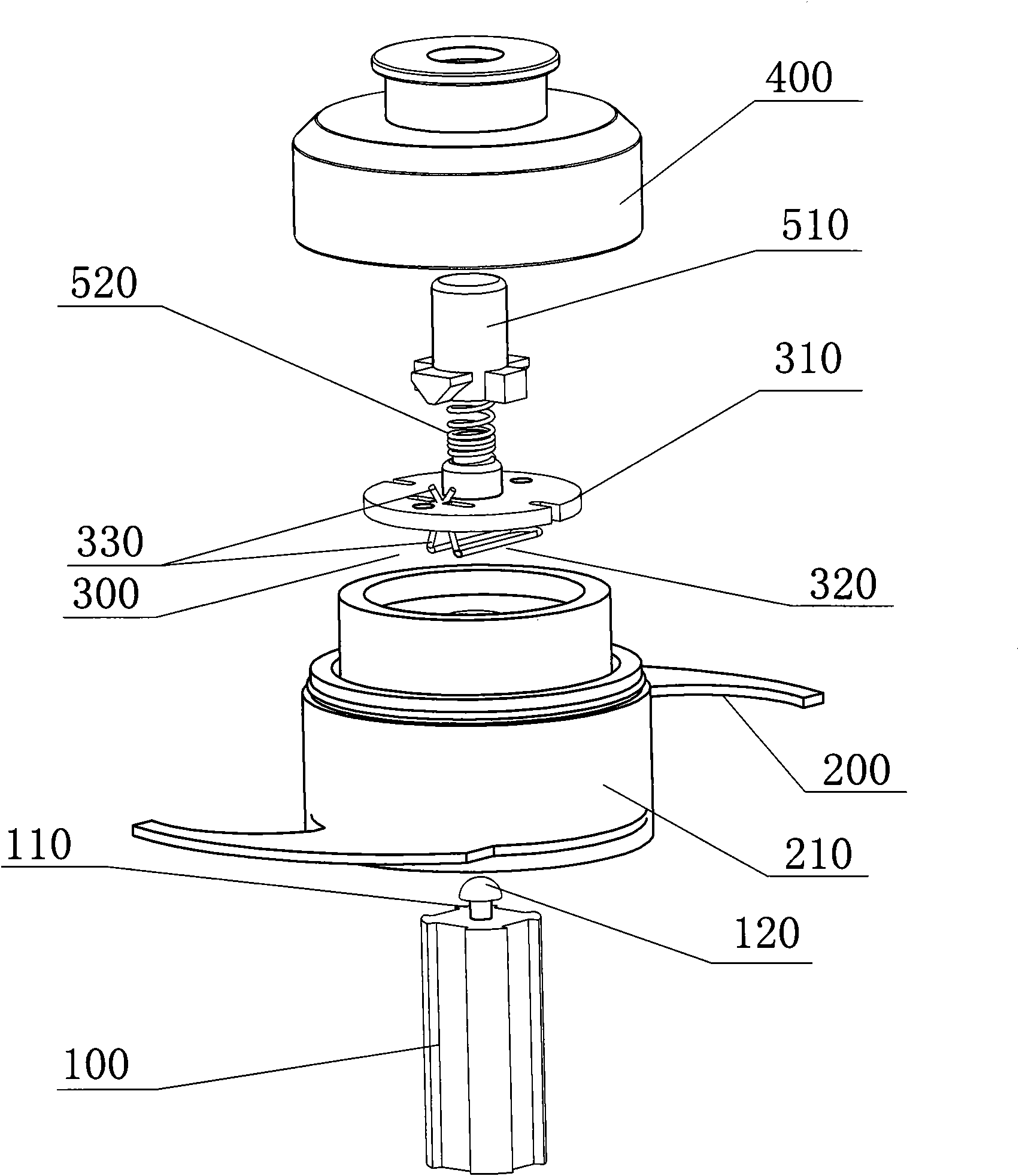

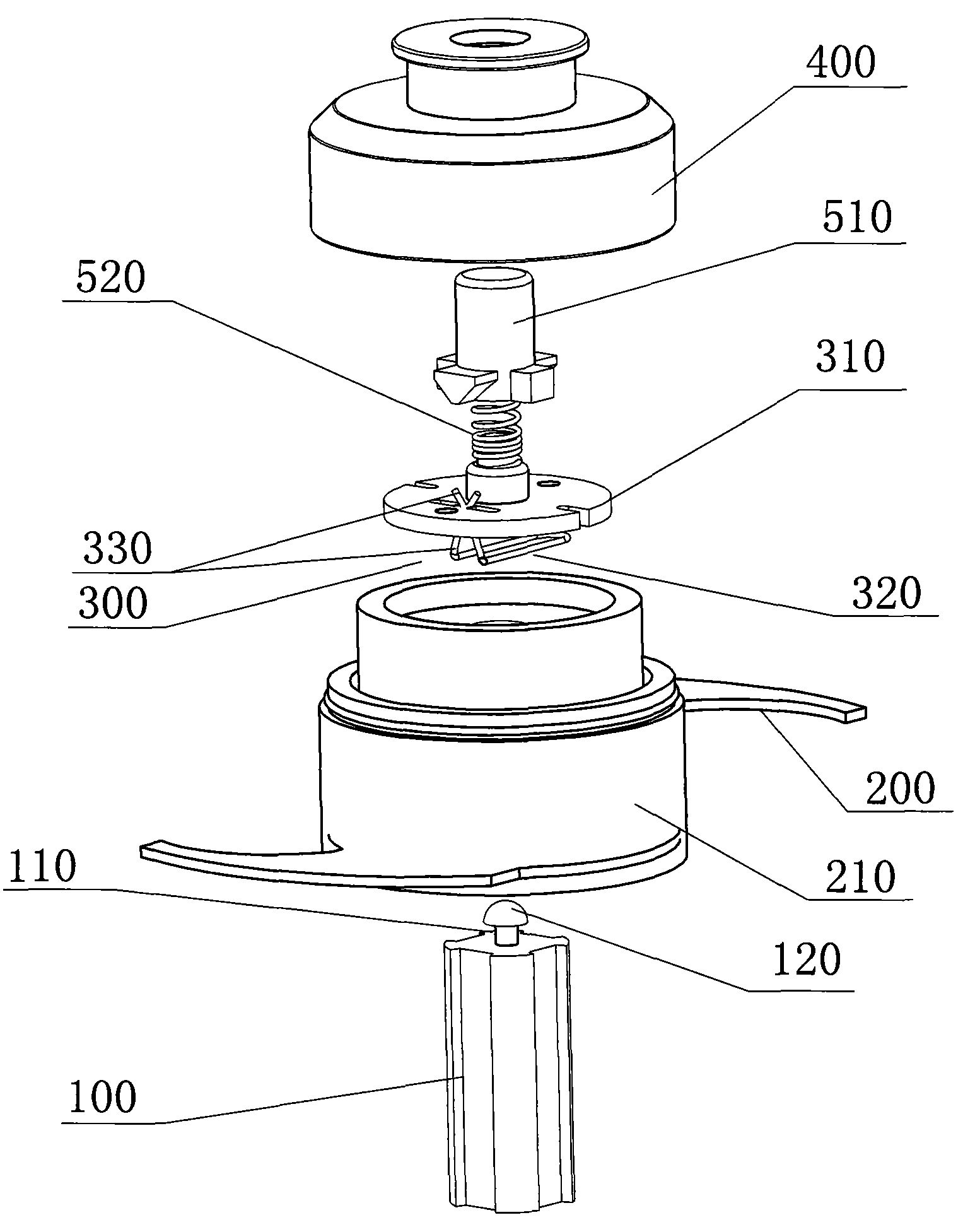

[0015] Such as figure 1 As shown, a locking device, specifically a knife locking device for a kitchen food mixer, includes a shaft, that is, a transmission shaft 100, and also includes a target part, that is, a knife 200. A locking groove 110 is provided on the transmission shaft 100, and the transmission The top 120 of the shaft 100 is a mushroom-shaped arc surface; it also includes a lock spring 300 matching the lock groove 110, the cutter 200 is arranged on the fixed frame 210, an upper cover 400 is arranged on the fixed frame, and the lock spring 300 is arranged on On the lock spring frame 310 , the lock spring frame 310 is embedded in the fixed frame 210 , so that the lock spring frame 310 is connected with the fixed frame 210 . The lock spring 300 is "L"-shaped, including a "U"-shaped locking part 320 at the bottom and an "X"-shaped fixing part 330 standing upright on the side. By opening the fixing part 330, the locking part 320 can also be opened. , the locking portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com