Device for pressing flat material

A technology of extrusion processing and flattening, which is applied in the direction of flat products, wood processing appliances, applications, etc., can solve the problems of not being disclosed, and achieve the effect of increasing the pressure application time and increasing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

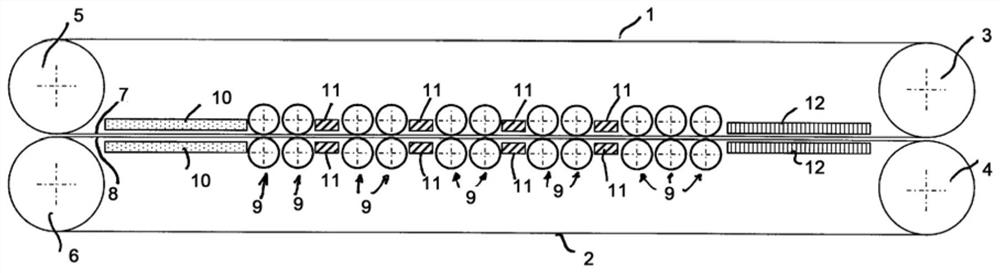

[0037] figure 1 A double-belt press with an upper pressing belt 1 and a lower pressing belt 2 is schematically shown in lateral cross-section. The continuous pressing belt 1 or 2 is guided around an upper drive roller 3 or a lower drive roller 4 and around an upper guide roller 5 or a lower guide roller 6 , respectively. Between the working section 7 of the upper pressing belt 1 and the working section 8 of the lower pressing belt 2 is guided the flat material to be processed, not shown here, which is conveyed by the surrounding pressing belts 1 and 2 in the conveying direction. (exist figure 1 Guided together from left to right). Along the working legs 7 and 8 are arranged pressure roller pairs 9 with which the upper working leg 7 and the lower working leg 8 are pressed against the flat material to be processed, not shown here . In addition, in figure 1 Heating elements, not shown separately, are arranged along the working legs 7 and 8 in the main heating zone 10 and in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com