Extruding and edge cutting equipment for rubber product

A rubber product and edge trimming technology, applied in metal processing and other directions, can solve the problems of uneven extrusion effect, uncontrollable extrusion strength, unsuitable for large batches, etc., to achieve uniform extrusion effect and good bonding effect. , the effect of convenient operation

Active Publication Date: 2017-09-01

惠州市卓普科技有限公司

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Traditionally, if you want to bond two rubber products together, in addition to sprinkling the joint with glue, you can also bake the surface of the rubber to a state that is liquid but not flowing, and then The other is also operated in the same way, a group of baking surfaces are effectively bonded, squeezed with professional tools, and air-dried, and the two rubber products are combined. If the baking time is too long, the gap will be squeezed There will be excess rubber squeezed out, usually after drying, it is cut manually, the strength is relatively high, it is not suitable for mass production, if you want to change the size of the combined rubber, you need to transport the rubber to a professional cutting tool In the middle, because the weight of the rubber is relatively large, it is more troublesome during the moving process. If there is no solidified gap and dust is stuck, it will affect the final bonding result. The traditional extrusion strength is not good. Control, the effect of extrusion is not uniform, so in order to solve these problems, it is more important to design an equipment that integrates extrusion and trimming for the production of rubber products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

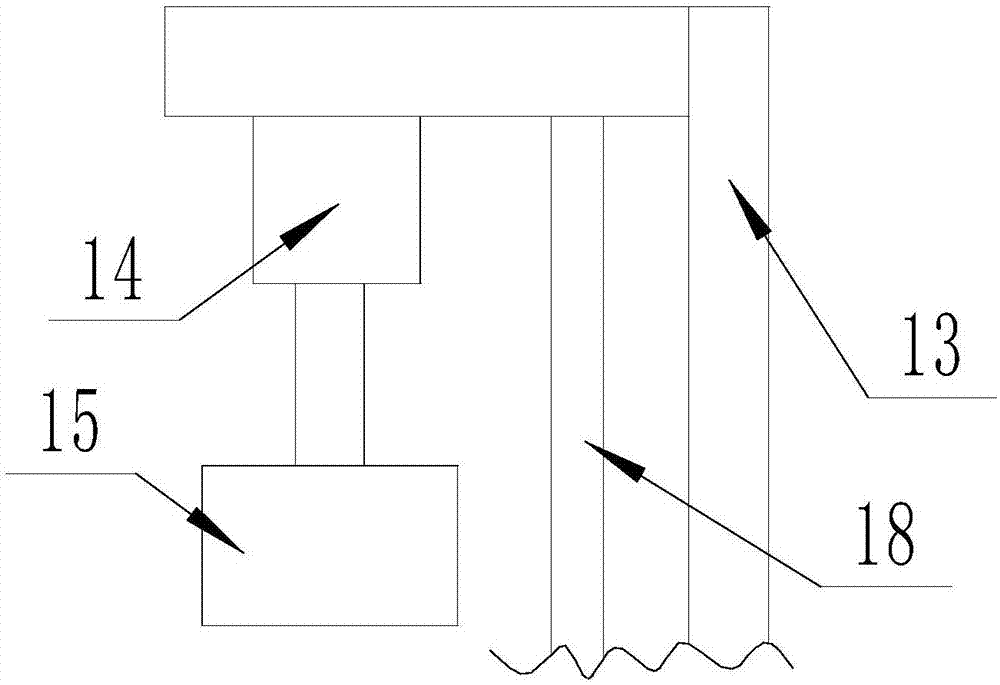

[0024] Embodiment 2: The hydraulic push rod 14 can be replaced by a linear motor, which can also achieve the telescopic effect, and other structures are the same as in Embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

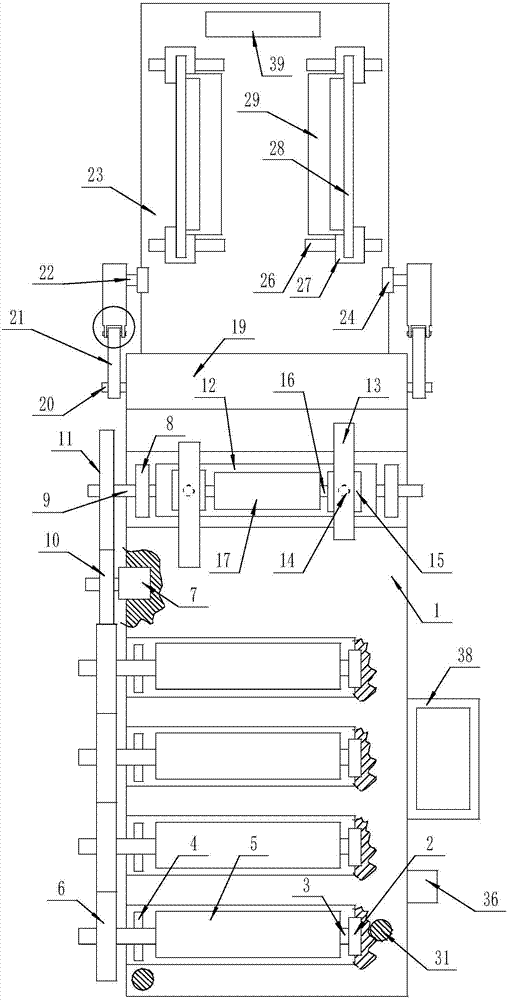

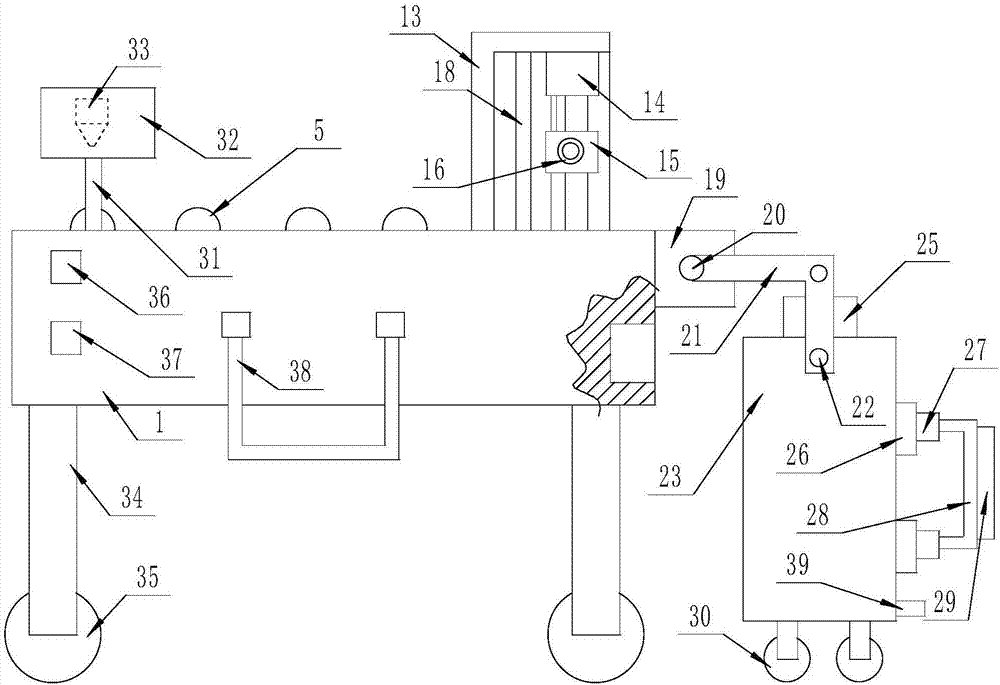

The invention discloses extruding and edge cutting equipment for a rubber product. The extruding and edge cutting equipment comprises a strip-shaped bearing plate; an extruding mechanism is arranged on the upper surface of the strip-shaped bearing plate; and a swinging edge cutting mechanism is arranged in the position, close to the extruding mechanism, of the strip-shaped bearing plate. The extruding and edge cutting equipment has the beneficial effects that operation is convenient, it is convenient to control the extruding degree, the extruding effect is even, the attaching effect is good, cutting in the fixed length is conveniently conducted on extruded spare rubber, assembly line production is achieved, the situation that operation is conducted in large volumes is facilitated, and the labor intensity is relieved.

Description

technical field [0001] The invention relates to the electromechanical field, in particular to an extrusion trimming device for rubber products. Background technique [0002] Electromechanical is the common use of machinery and electricity. Electricity is used to control the operation of machinery to work according to regulations. For rubber products, extrusion is required when laminating, and the strength of extrusion is controlled by circuits. [0003] Traditionally, if you want to bond two rubber products together, in addition to sprinkling the joint with glue, you can also bake the surface of the rubber to a state that is liquid but not flowing, and then The other is also operated in the same way, a group of baking surfaces are effectively bonded, squeezed with professional tools, and air-dried, and the two rubber products are combined. If the baking time is too long, the gap will be squeezed There will be excess rubber squeezed out, usually after drying, it is cut manua...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C65/28B29C65/80B26D1/02

CPCB26D1/025B29C65/28B29C65/80B29C66/41B29C66/81B29C66/90

Inventor 侯新源

Owner 惠州市卓普科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com