Forward extrusion forging apparatus and forward extrusion forging method

An extrusion direction and extruded technology, applied in forging/pressing/hammer devices, manufacturing tools, metal extrusion, etc., can solve the confusion of orientation, differences in ease of extrusion, and difficulty in manufacturing high anisotropic rare earths Magnets, etc., to achieve the effects of uniform extrusion, suppression of strain distribution, and suppression of uneven strain distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

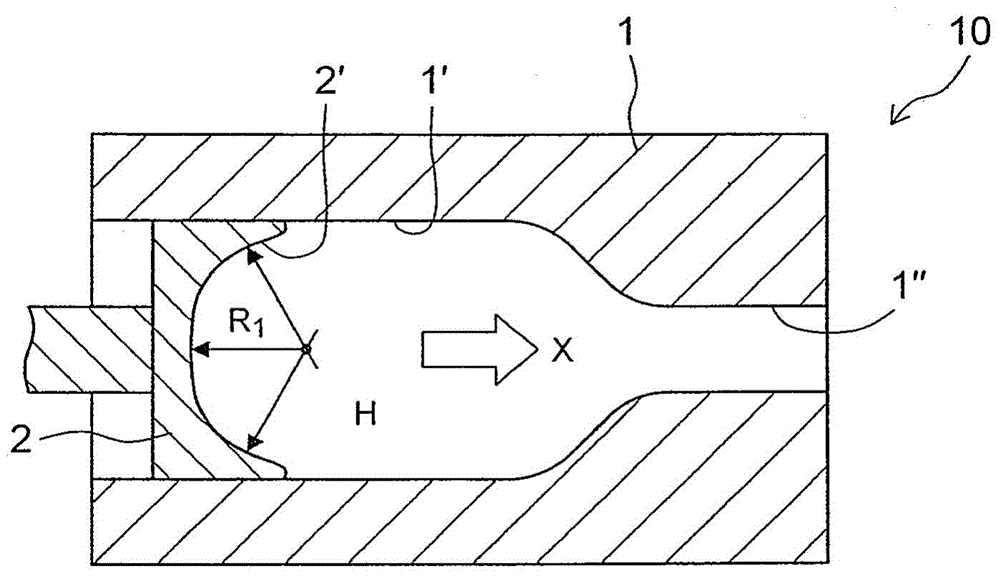

[0063] (forward extrusion forging method in embodiment 1) Figure 3A and 3B so Figure 3A and Figure 3B The order of is showing the flowchart of the forward extrusion forging method according to Embodiment 1 of the present invention.

[0064] First, if Figure 3A shown, ready figure 1 The forging device 10 is shown, and the workpiece W is placed in the hollow portion H of the die 1 of the forging device 10 (first step).

[0065] Next, if Figure 3B As shown, in a state where the inside of the hollow portion H is heated to a predetermined temperature, the punch 2 is slid in the hollow portion H, and the workpiece W is extruded forward to be forged by the extrusion surface 2' of the punch 2. As a result, producing Figure 4 The forged product shown is WT (second step).

[0066] During extrusion by the punch 2, the outer peripheral portion of the workpiece W receives shear friction F from the inner peripheral portion 1' of the die 1 and is difficult to extrude smoothly tha...

Embodiment 2

[0075] (forward extrusion forging method in embodiment 2) Figure 7A and 7B so Figure 7A and Figure 7B The sequence of 1 is a flow chart showing the forward extrusion forging method according to Embodiment 2 of the present invention, that is, the relay extrusion forging method in which a plurality of forged products are manufactured while being continuously added.

[0076] First, if Figure 7A shown, ready figure 1 The forging device 10 is shown, and the workpiece W is placed in the hollow part H of the die 1 of the forging device 10, and the punch 2 is slid. As a result, the first forged product WT1 is produced (first and second steps). Next, the punch 2 is returned backward, and another workpiece W is placed in the hollow portion H. As shown in FIG.

[0077] Next, the workpiece W is extruded forward to be forged by sliding the punch 2 again, and the second forged product WT2 is continuously added behind the first forged product WT1 (third step).

[0078] Here, an ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com