Laundry liquid and preparation method thereof

A technology for laundry detergent and foam control agent, applied in the field of detergents, can solve problems such as unsatisfactory results and difficult removal, and achieve the effects of strong anti-fouling redeposition ability, improved detergency, and reduced production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The present embodiment is comparative example, what adopt is prior art, and the composition of its laundry detergent is as shown in table 1, and the preparation step of laundry detergent is as follows:

[0079] (1) Pour deionized water into the stirring pot, start stirring, and heat to 40°C-60°C;

[0080] (2) Add alkylbenzenesulfonate anionic surfactant and AES to the stirring pot until the dissolution is complete;

[0081] (3) drop into the fatty alcohol polyoxyethylene ether nonionic surfactant to the stirring pot until completely dissolving;

[0082] (4) drop into fatty acid salt, sodium citrate, sodium borate, calcium chloride, sodium formate, propylene glycol to stirring pot;

[0083] (5) adjust the pH value to 7-9;

[0084] (6) Put protease, amylase, cellulase, lipase, mannanase, flavor, silicone defoamer, whitening agent, preservative into the stirring pot, stir for 5 minutes, take a sample and test it, and it can be released if it passes the test material pac...

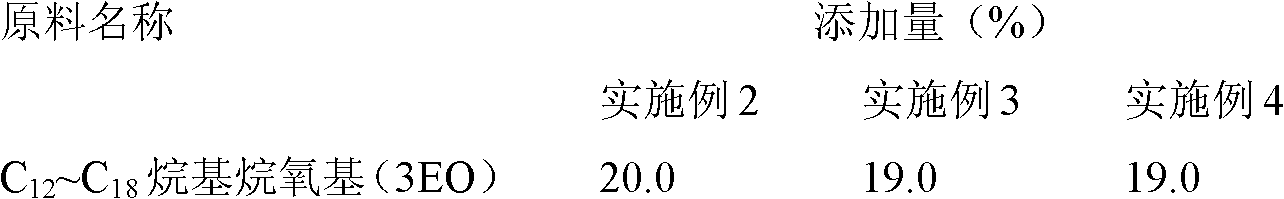

Embodiment 2~4

[0112] Examples 2-4 are specific examples of the present invention. The composition of the laundry detergent contains a polymer system, and the preparation method provided by the present invention is adopted, which reduces production time and improves production efficiency.

[0113] The composition of embodiment 2~4 washing liquid is as shown in table 2, and the preparation step of washing liquid is as follows:

[0114] (1) Pour deionized water into the stirring pot, start stirring, and heat to 40°C;

[0115] (2) Add AES to pre-dissolving pot A, add 1.5% lipophilic modified polymer, and stir evenly;

[0116] (3) Add fatty alcohol polyoxyethylene ether nonionic surfactant in pre-dissolving pot B, then add remaining lipophilic modified polymer, carboxylic acid polymer and stir evenly;

[0117] (4) Add the AES and the fatty alcohol polyoxyethylene ether nonionic surfactant in the predissolved pot to the stirring pot, and stir evenly;

[0118] (5) drop into fatty acid salt, sodi...

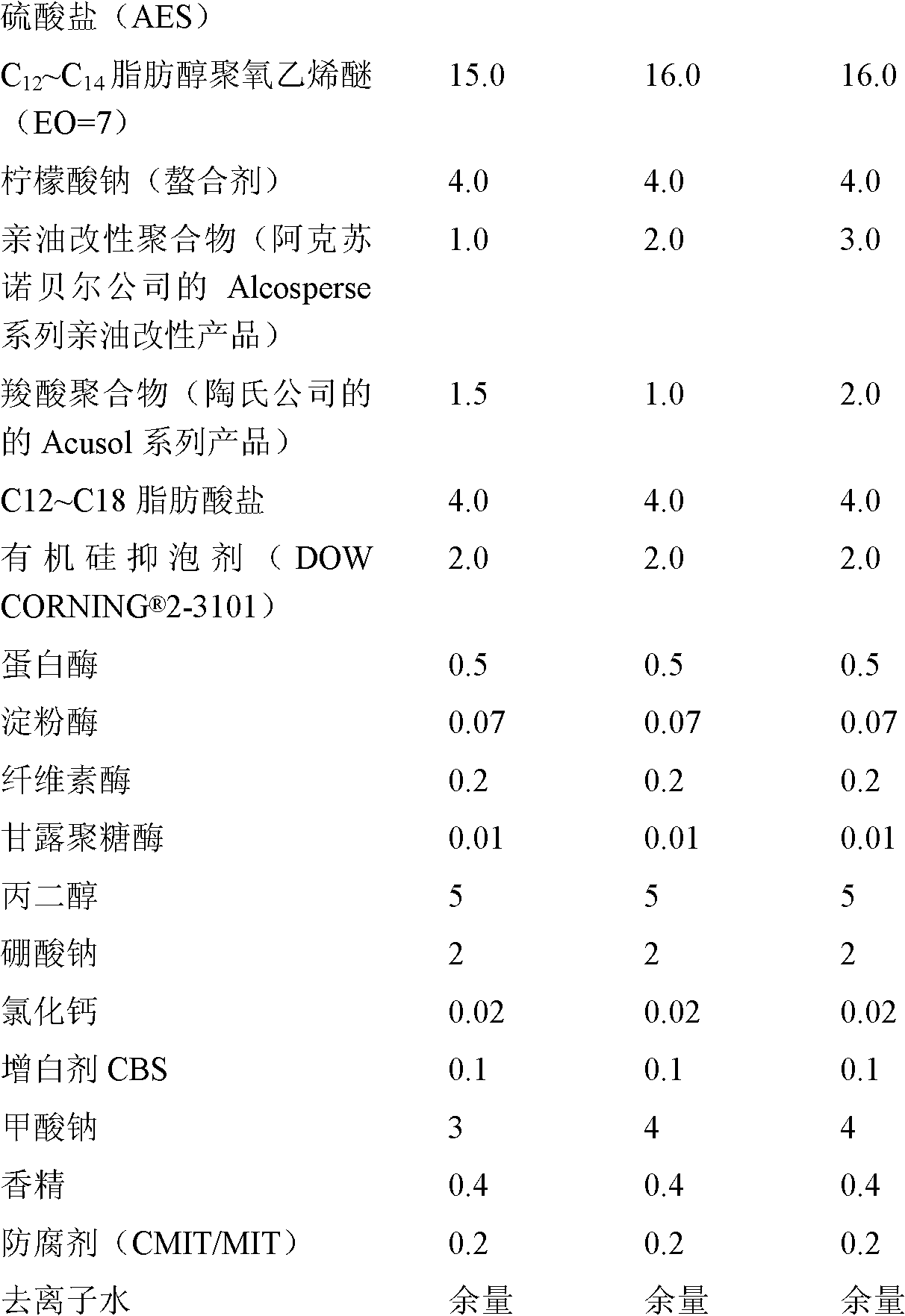

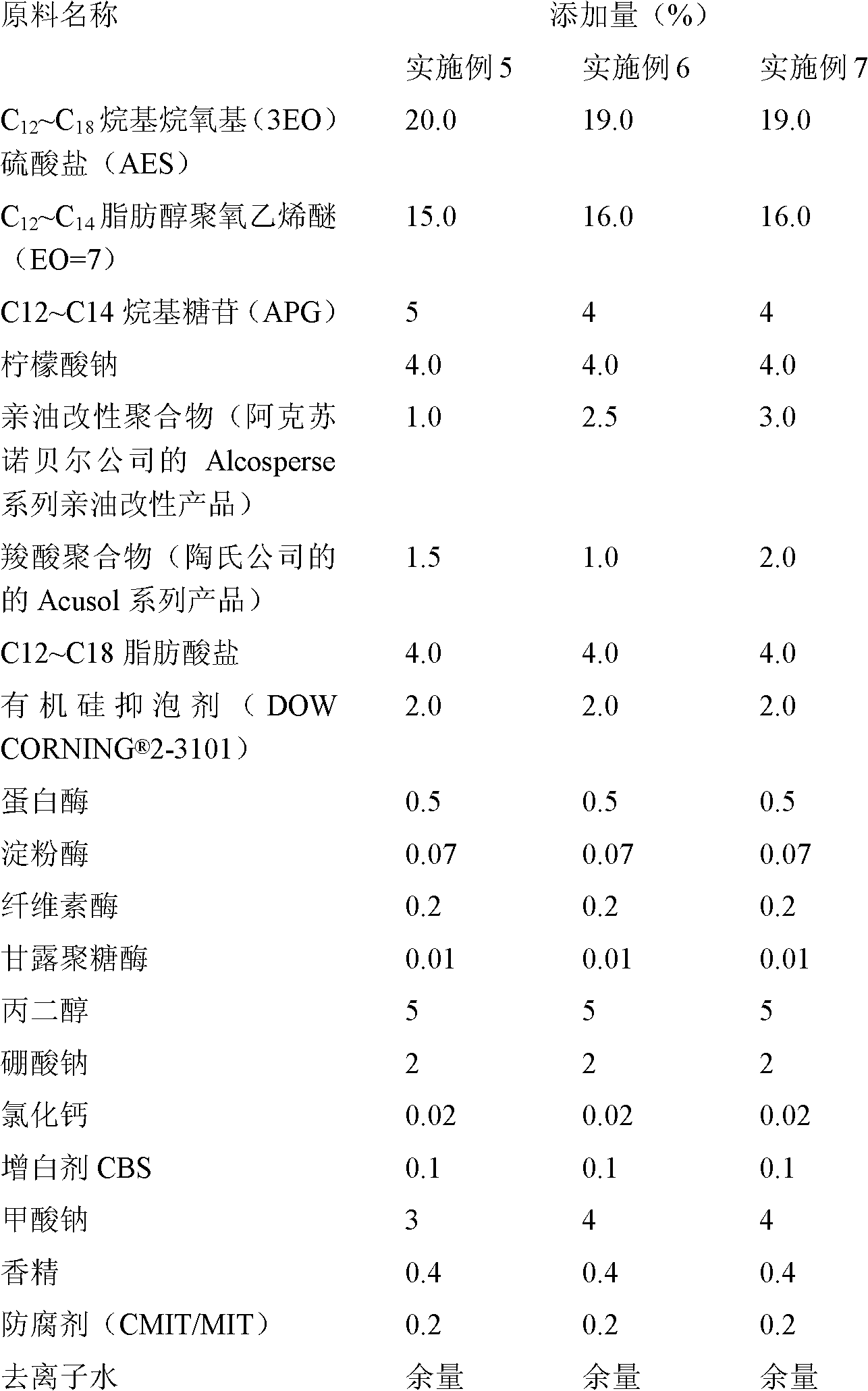

Embodiment 5~7

[0126] Embodiments 5 to 7 are specific examples of the present invention, and the composition of the laundry detergent of Embodiments 5 to 7 is as shown in Table 3, and the preparation steps of the laundry detergent are as follows:

[0127] (1) Pour deionized water into the stirring pot, start stirring, and heat to 60°C;

[0128] (2) Add AES in pre-dissolving pot A, add 0.5% lipophilic modified polymer and stir evenly;

[0129] (3) Add fatty alcohol polyoxyethylene ether and APG nonionic surfactant in predissolving pot B, then put remaining lipophilic modified polymer, carboxylic acid polymer into and stir;

[0130] (4) Add the anionic surfactant and the nonionic surfactant of the pre-dissolved pot in the stirring pot, and stir evenly;

[0131] (5) drop into fatty acid salt, sodium citrate, sodium borate, calcium chloride, sodium formate, propylene glycol to stirring pot;

[0132] (6) adjust the pH value to 9;

[0133] (7) Put protease, amylase, cellulase, mannanase, essenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com