Sanitary faucet with improved flow restriction feature and foam control feature

a flow restriction and faucet technology, applied in the field of faucets, can solve the problems of unsatisfactory foaming, unfavorable bacterial growth in the valve, and alter the taste and appearance of certain fluids, so as to reduce foam and facilitate cleaning of valve elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

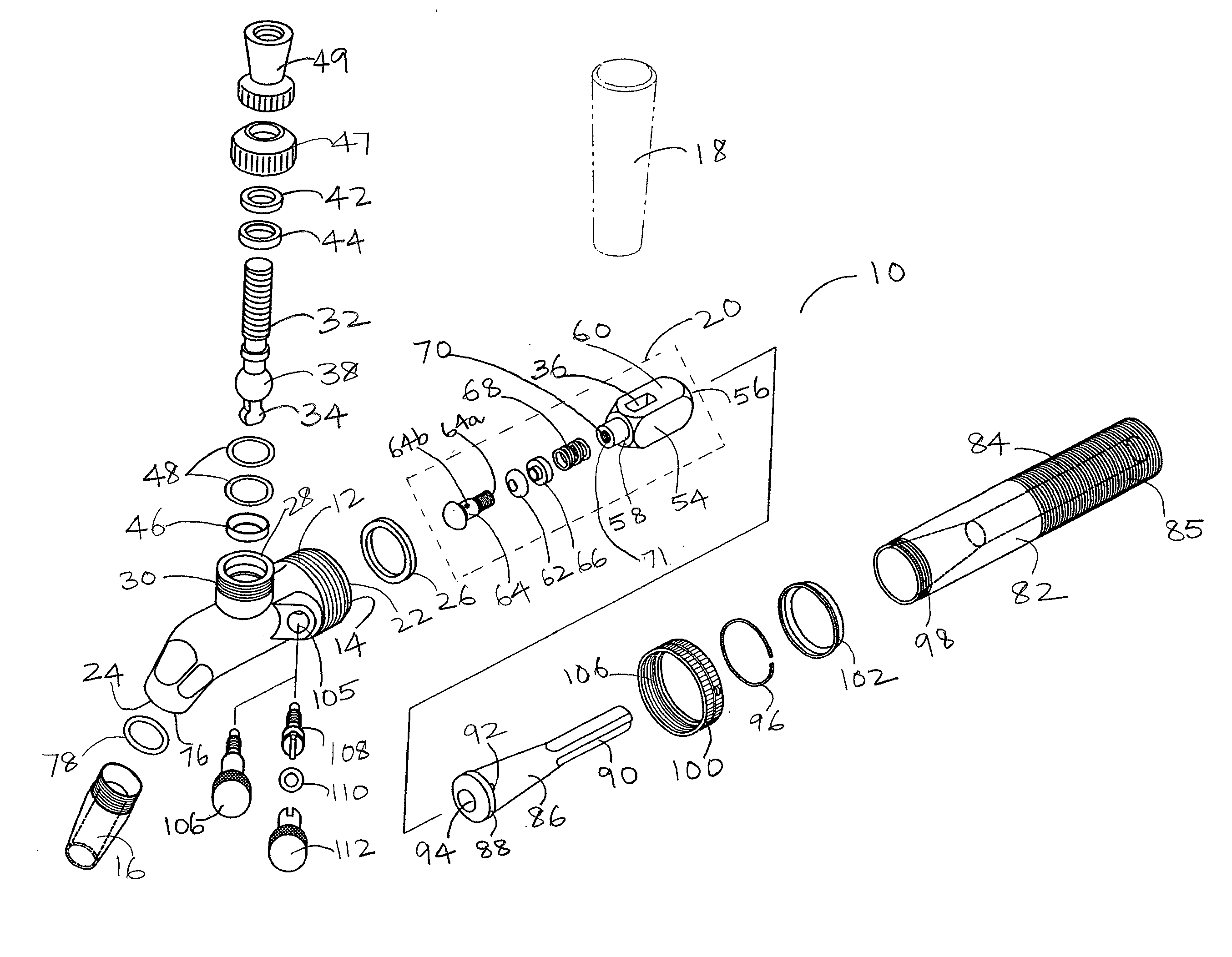

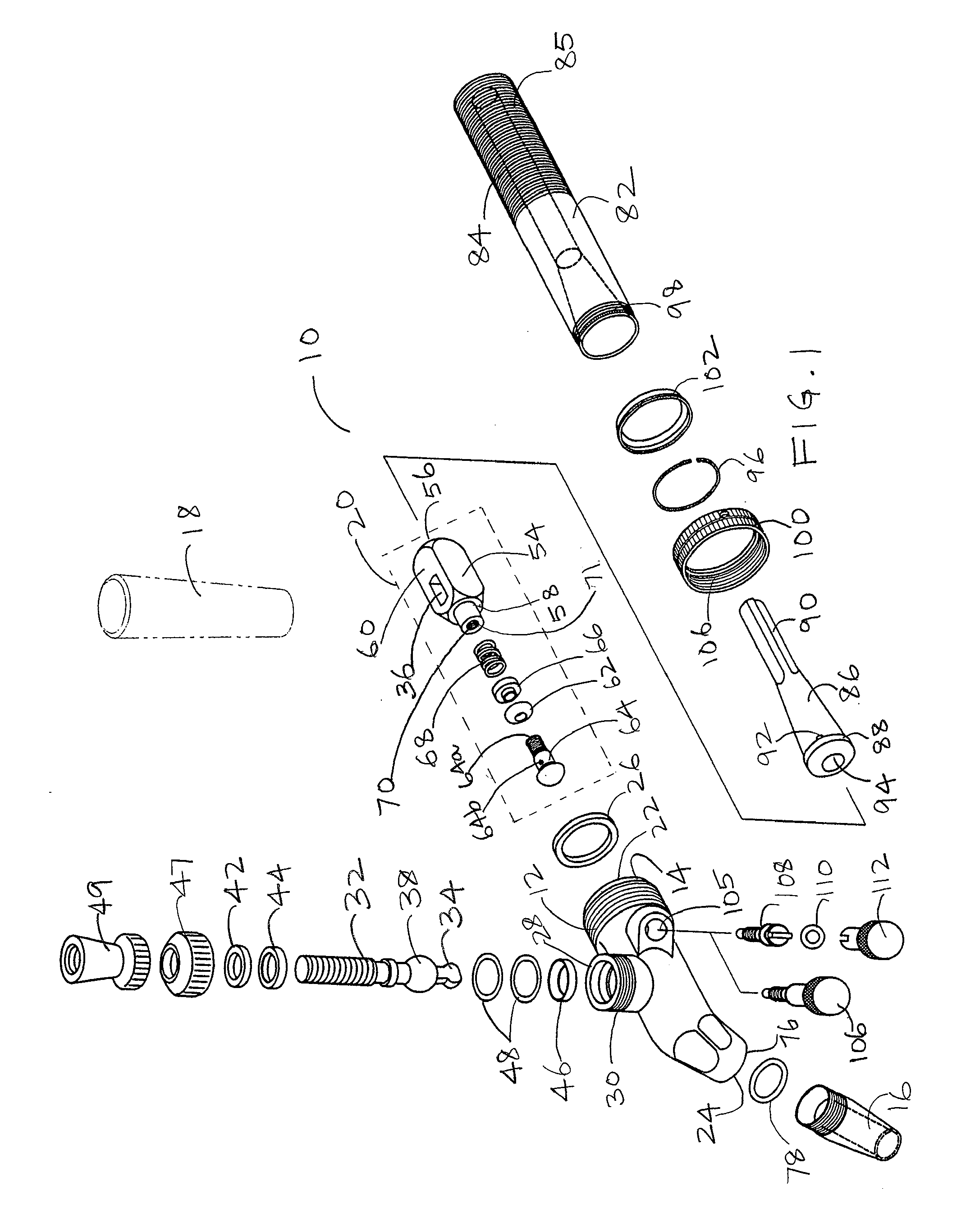

[0024] A dispensing faucet is provided that is usable in any system in which a faucet is selectively operated to dispense materials from a pressurized source. For instance, it is applicable to “tapper” faucets configured to dispense beer or another pressurized liquid from a keg or another pressurized container. It is also applicable to condiment faucets configured to dispense ketchup, mustard or relish from a container. For the purposes of describing this invention, both non-viscous and viscous materials, such as beer and hot dog relish, shall be considered fluids or liquids.

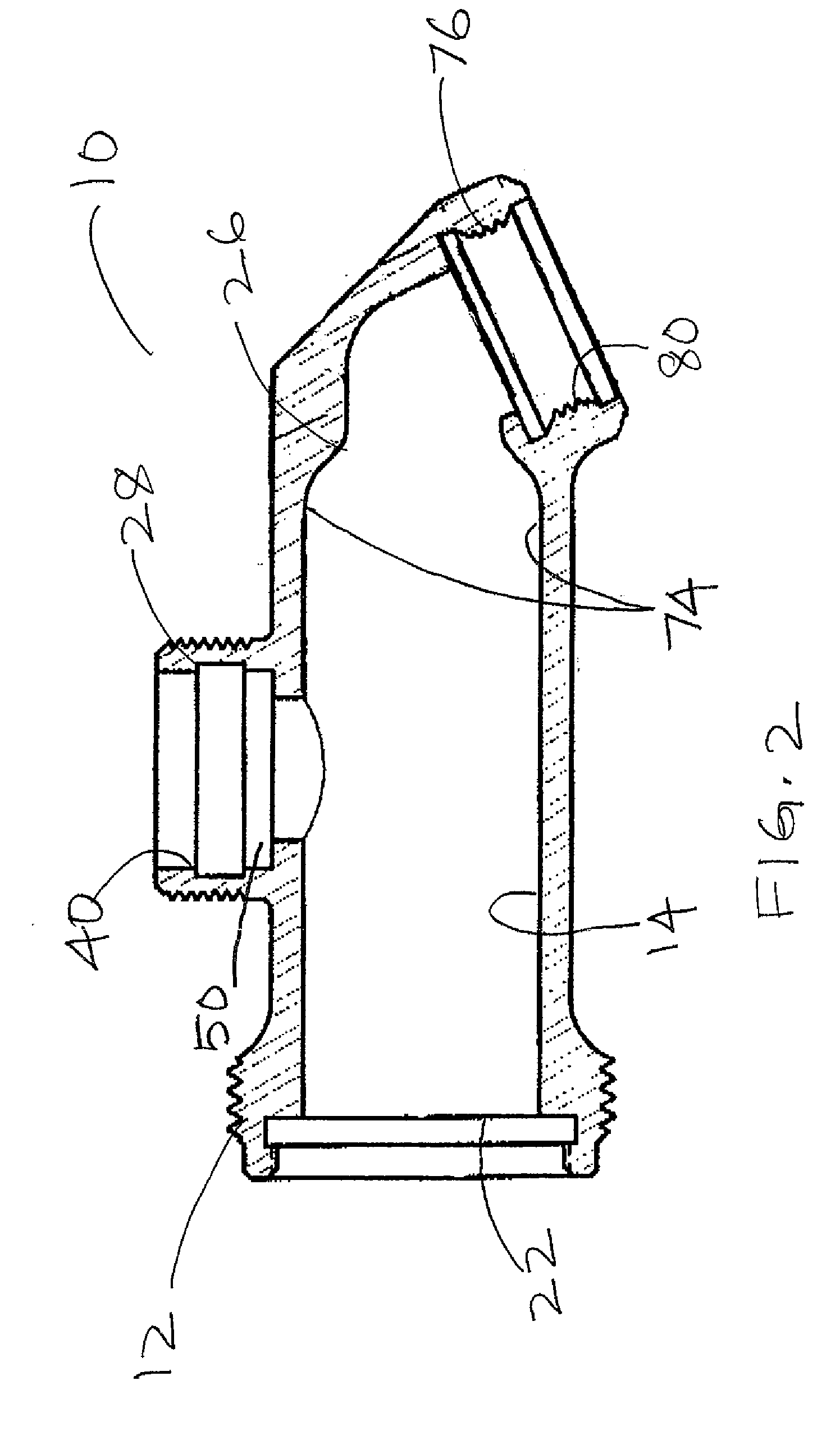

[0025] The faucet comprises a valve body and a plunger which is mounted in a bore in the valve body for reciprocating movement therein. The bore has an inlet port that opens into a passage adapted for connection to a pressurized container or other source of pressurized fluid, and an outlet port that opens into a dispensing spout adapted to deliver the fluid from the faucet. A handle having a pivotable lever is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com