Organic-silicon composition, preparation and application thereof

A composition and silicone technology, applied in chemical/physical processes, foam dispersion/prevention, transportation and packaging, etc., can solve the problems of high content of defoaming agent and high turbidity, and achieve excellent clarity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

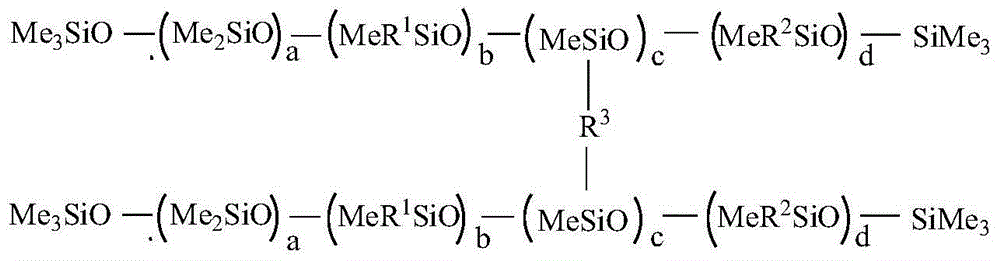

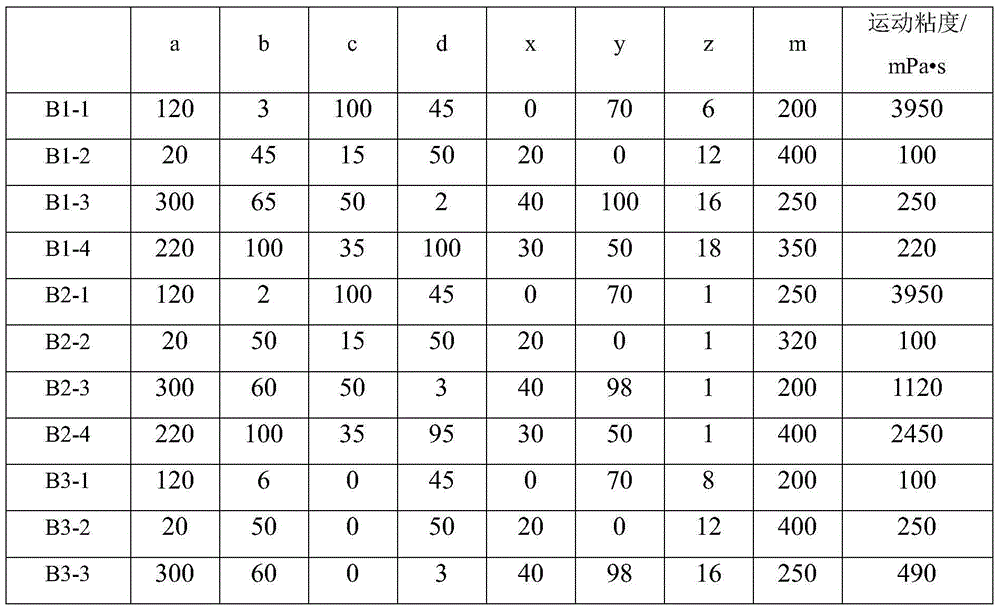

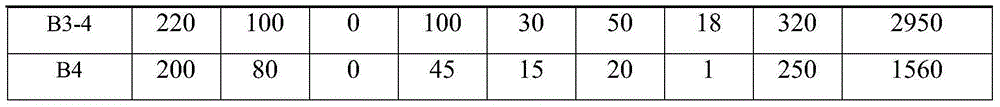

[0080] The preparation method of component B:

[0081] The corresponding modifying group R with unsaturated double bonds shown in Table 1 1 , R 2 and R 3 It is obtained by reacting with hydrogen-containing polyorganosiloxane under the action of isopropanol solution of chloroplatinic acid with a platinum content of 1-20ppm, in which various modified groups are grafted to hydrogen-containing polyorganosiloxane through random polymerization on the oxane backbone. The hydrogen-containing polyorganosiloxane is at least one hydrogen-containing polyorganosiloxane whose general structure is as follows: Me 3 SiO(MeHSiO) p (Me 2 SiO) q SiMe 3 , where the corresponding values are: Me is methyl, b+c+d=p, a=q; each molecule has at least 2 silicon-bonded hydrogen atoms; the kinematic viscosity at 25°C is 20~ 5,000mPa·s.

[0082] Component C: polyether polyol

[0083] Table 2 Values of variables of different polyether polyols

[0084]

Embodiment 1-10

[0086] The defoamer products of Examples 1-10 were prepared according to the formula in Table 3.

[0087] Table 3 Defoamer components and ratio

[0088]

Embodiment 1-2

[0089] The preparation method of embodiment 1-2:

[0090] Mix component A and component B prepared by the known technique shown in Table 3 and heat to 55°C. After stirring at 150rpm for 0.5h, keep the temperature constant and add C1. After stirring evenly, pass through a colloid mill to homogenize After chemical treatment, add C2 and C3 and stir evenly to obtain the defoamer composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com