Air flotation treatment method for high-concentration salt-making brine

A treatment method and high-concentration technology, which are applied in seawater treatment, water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of large bubble size, large energy consumption and high salt content in brine, etc. To achieve the best effect and reduce the load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: When this technology is used in the production of food salt, it is required to prohibit the addition of chemical agents in the process flow. In this case, the dosage of coagulant is 0 ppm.

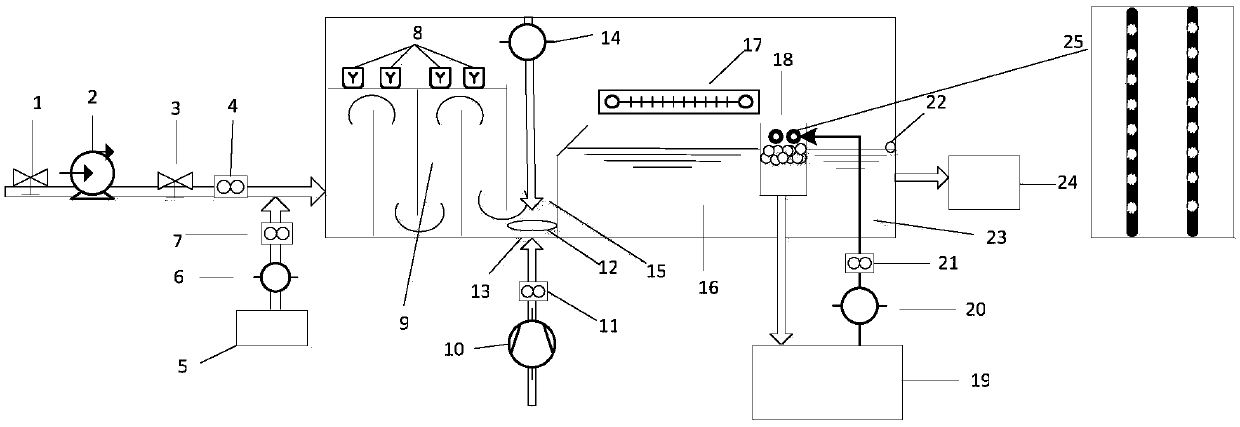

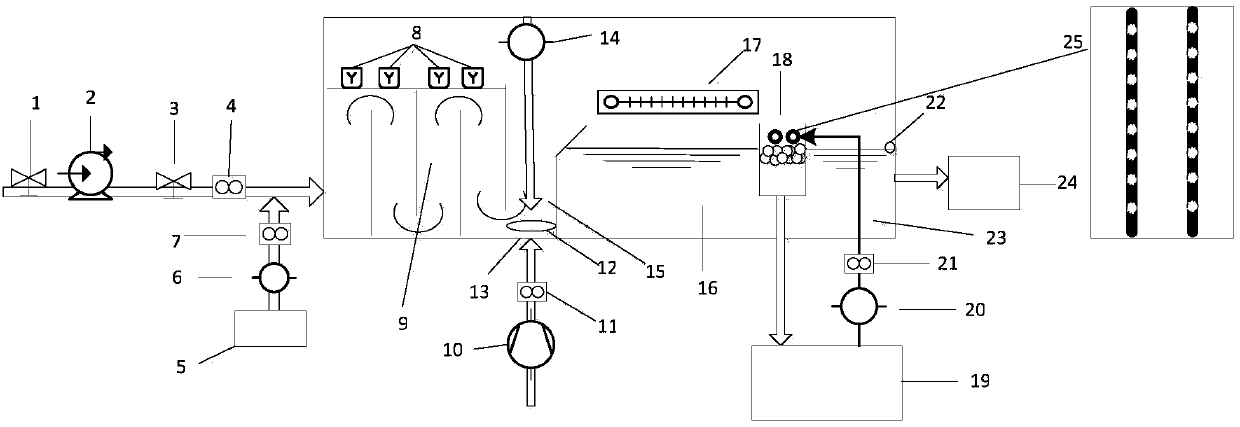

[0034] 1) Water intake stage: open the manual valve 1 in front of the water intake pump, heat the high-concentration salt-making brine with a Baume degree of 18-24°Bé to 25-35°C within its suitable range, then enter the water intake pump 2, and turn on the water intake The water manual valve 3 makes the salt-making brine enter the air flotation contact zone 15, and the water inlet flowmeter 4 monitors the water inlet flow rate simultaneously.

[0035] 2) Air flotation stage: open the aeration pump 10 and the intake flow meter 11 to monitor the aeration rate, and the aeration enters the brine through the microporous aerator 12, wherein the microporous aerator is a plurality of groups of aeration units, the described The aeration unit includes a central pipe communicated wi...

Embodiment 2

[0037] Example 2 is the same as Example 1, except that the aperture of the aeration head in the air flotation stage of step 2) is 0.08 μm, and the aeration intensity is 3Nm 3 / (m 2 / h), the water velocity in the aeration zone is 9m / h, and the contact time is 20min.

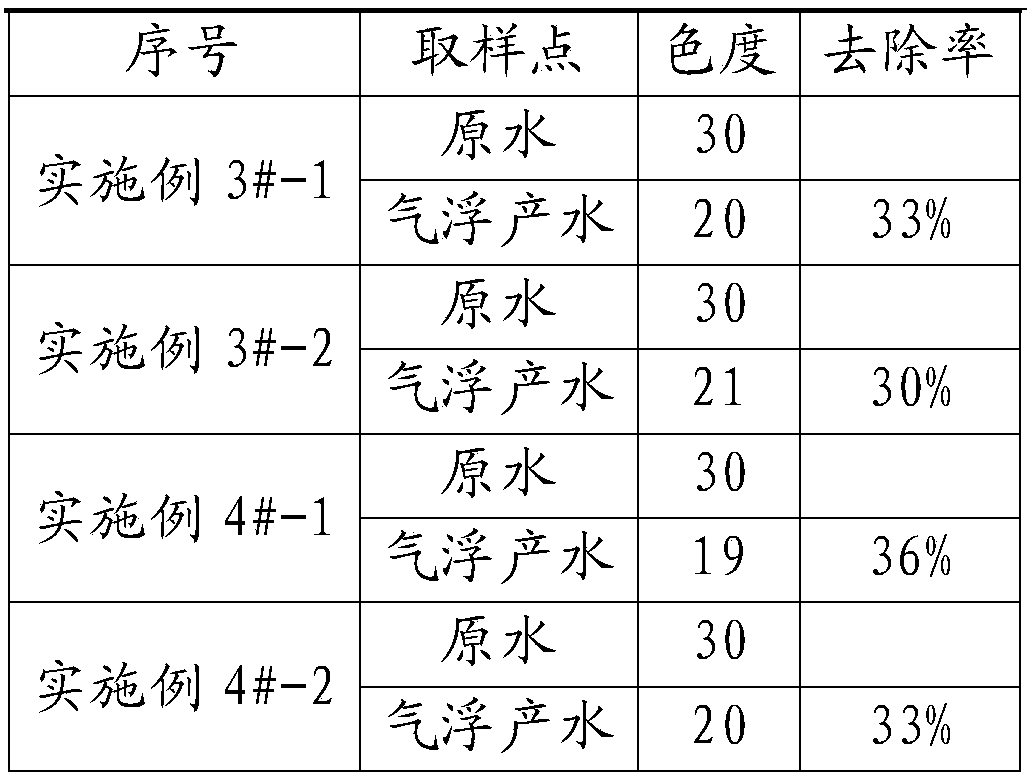

Embodiment 3

[0038] Example 3 is the same as Example 1, except that the aperture of the microporous aerator in the air flotation stage of step 2) is equal to 0.1 μm, and the aeration intensity is 2Nm 3 / (m 2 / h), the water flow rate in the aeration zone is 7m / h, and the contact time is 15min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com