Method for preparing porous oxide film on metal carrier surface

A technology of porous oxide and metal carrier, which is applied in the coating process of metal materials, coating, etc., can solve the problems of shortening the drying process time of the film layer and reducing the sintering temperature of the film layer, so as to shorten the process time, reduce the sintering temperature, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

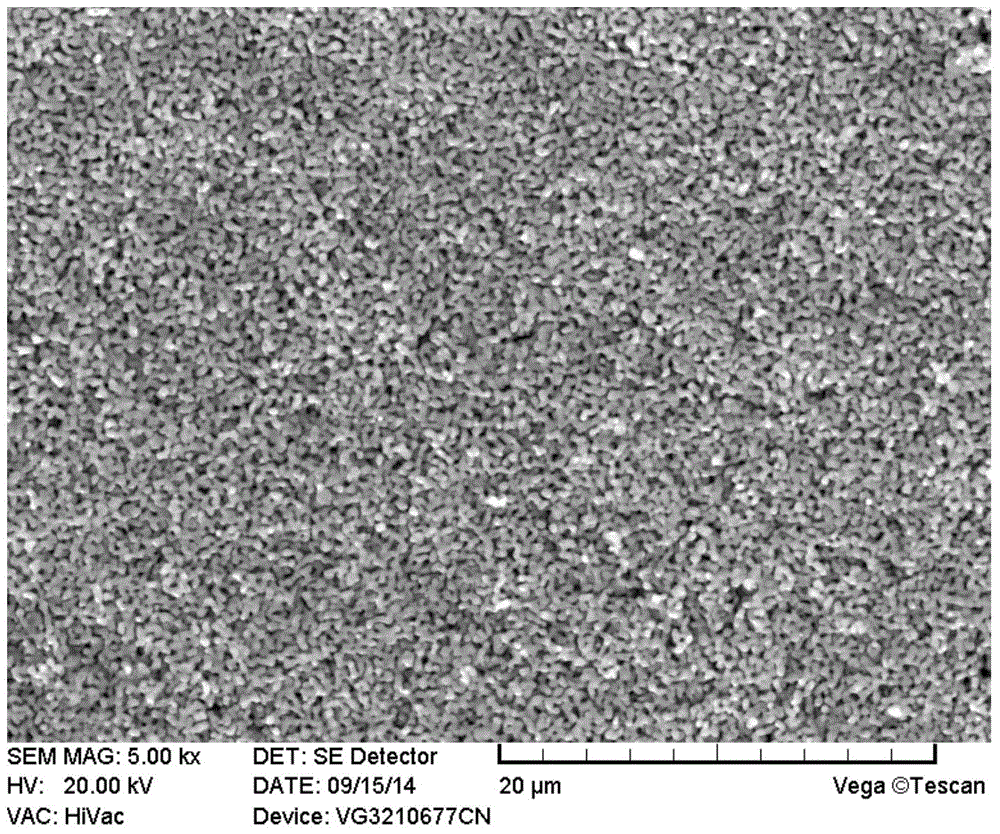

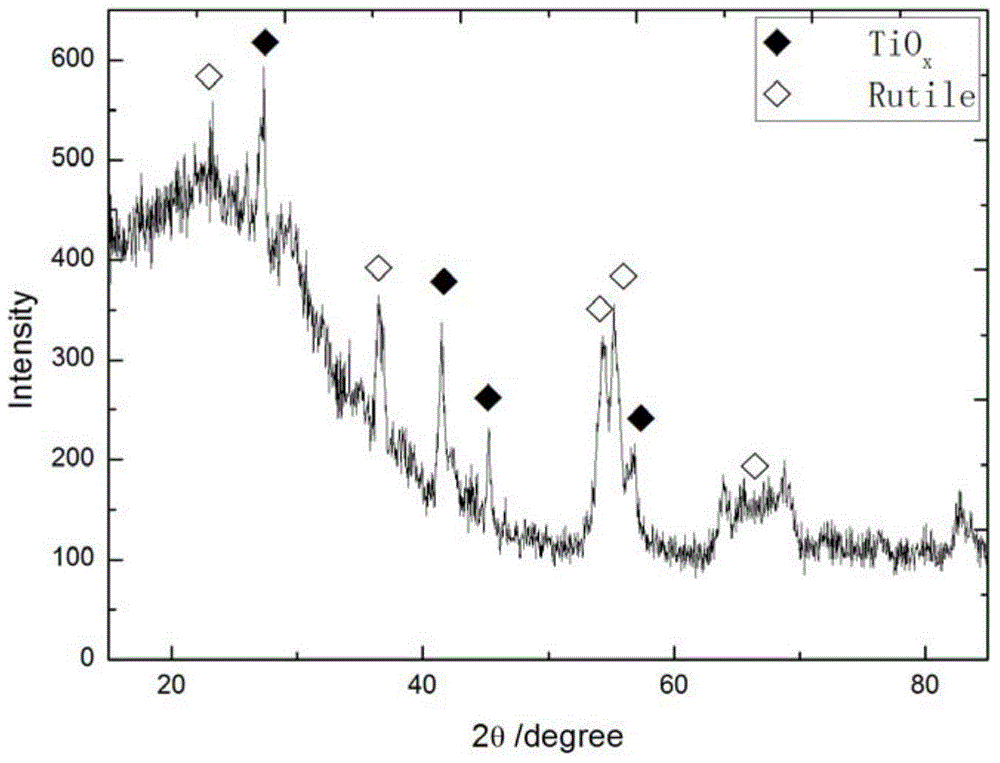

[0036] Prepare a porous titanium oxide film on the surface of porous titanium with a porosity of 20%. The specific method comprises the following steps:

[0037] Step 1, performing conventional pickling treatment on the porous titanium to remove scale and impurities on the surface of the porous titanium;

[0038]Step 2, select oxide (titanium dioxide) and oxide sol (titanium dioxide sol) according to the porous titanium oxide film to be prepared, then mix the following raw materials by mass percentage to make slurry: titanium dioxide 20%, titanium dioxide sol 45% , polyethylene glycol (PEG2000) 25%, mass percent concentration is 0.2% PVB ethanol solution 8%, volume percent concentration is 5% glycerol ethanol solution 1.5%, boron oxide 0.5%; in the titanium dioxide sol The concentration of titanium dioxide is 0.5mol / L;

[0039] Step 3, coating the slurry described in step 2 on the surface-treated porous titanium surface in step 1 by spraying;

[0040] Step 4. Dry the porous ...

Embodiment 2

[0044] Prepare a porous aluminum oxide film on the surface of 316L stainless steel with a porosity of 30%, and the specific method includes the following steps:

[0045] Step 1. Carry out conventional sandblasting (shot) treatment to 316L stainless steel to remove scale and impurities on the surface of 316L stainless steel;

[0046] Step 2, select oxide (Al2O3) and oxide sol (Al2O3 sol) according to the porous alumina film to be prepared, then mix the following raw materials by mass percentage to make slurry: 30% aluminum, 50% aluminum oxide sol, 15% polyethyleneimine, 5% PVB ethanol solution with a mass percentage concentration of 0.2%; the concentration of aluminum oxide in the aluminum oxide sol is 0.025mol / L;

[0047] Step 3, coating the slurry described in step 2 on the surface-treated 316L stainless steel surface in step 1 by dipping and pulling;

[0048] Step 4. Dry the 316L stainless steel covered with slurry in step 3 at 80°C for 24 hours, then place it in a sinter...

Embodiment 3

[0052] Prepare a porous zirconia film on a porous copper surface with a porosity of 25%, and the specific method comprises the following steps:

[0053] Step 1, carrying out conventional pickling treatment to the porous copper to remove oxide skin and impurities on the surface of the porous copper;

[0054] Step 2, select oxide (zirconia) and oxide sol (zirconia sol) according to the porous zirconia film to be prepared, then mix the following raw materials by mass percentage to make slurry: zirconium dioxide 20 %, 50% of zirconium dioxide sol, 15% of stearic acid, 10% of ethanol solution of phenolic resin with a mass percent concentration of 10%, 5% of copper oxide; the concentration of zirconium dioxide in the zirconium dioxide sol is 1mol / L;

[0055] Step 3, coating the slurry described in step 2 on the surface-treated porous copper surface in step 1 by spraying;

[0056] Step 4. Dry the porous copper covered with slurry in step 3 at 80°C for 24 hours, then place it in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com