A 12v start-stop lithium-ion battery electrolyte

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of rising battery resistance, reducing battery low-temperature performance, unable to ensure normal battery operation, etc., to reduce viscosity, widen operating temperature range, and improve ion conductivity. and film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

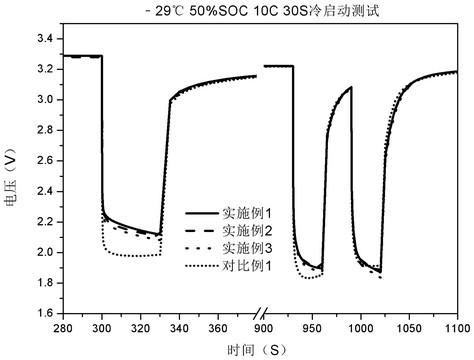

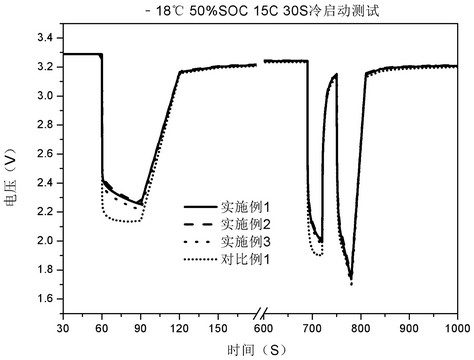

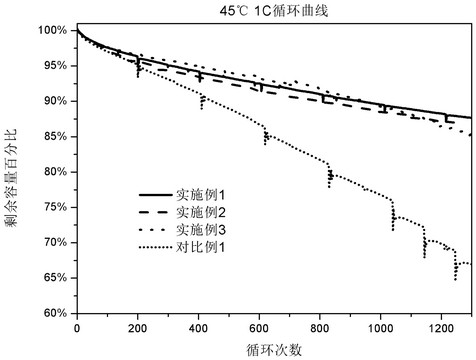

Embodiment 1

[0022] A 12V start-stop lithium-ion battery electrolyte, the components include lithium salts, organic solvents, and functional additives. The mass fractions of the components in the lithium salt in the electrolyte are: lithium hexafluorophosphate LiPF6 7.5%, lithium bisfluorosulfonyl imide LiFSI 8.4%. The mass fractions of the components of the organic solvent in the electrolyte are: 13% ethylene carbonate EC, 48% ethyl methyl carbonate EMC and 21% n-2,2,2-trifluoroethyl n-hexanoate TFENH. The mass fractions of functional additives in the electrolyte are: lithium difluorophosphate LiPO2F2 0.6%, vinylene carbonate VC 0.9% and beta-sulfopropionic anhydride SPA 0.6%.

Embodiment 2

[0024] A 12V start-stop lithium-ion battery electrolyte, the components include lithium salts, organic solvents, and functional additives. The mass fractions of the components in the lithium salt in the electrolyte are: lithium hexafluorophosphate LiPF6 8.8%, lithium bisfluorosulfonyl imide LiFSI 9%. The mass fractions of the components of the organic solvent in the electrolyte are: 12.5% ethylene carbonate EC, 47.5% ethyl methyl carbonate EMC and 20% n-hexanoic acid-2,2,2-trifluoroethyl ester TFENH. The mass fractions of functional additives in the electrolyte are: lithium difluorophosphate LiPO2F2 0.7%, vinylene carbonate VC 0.95% and beta-sulfopropionic anhydride SPA 0.55%.

Embodiment 3

[0026] A 12V start-stop lithium-ion battery electrolyte, the components include lithium salts, organic solvents, and functional additives. The mass fractions of the components in the lithium salt in the electrolyte are: lithium hexafluorophosphate LiPF6 7%, lithium bisfluorosulfonimide LiFSI 7.4%. The mass fractions of the components of the organic solvent in the electrolyte were: ethylene carbonate EC 13.5%, ethyl methyl carbonate EMC 49% and n-hexanoic acid-2,2,2-trifluoroethyl ester TFENH 21.5%. The mass fractions of functional additives in the electrolyte are: lithium difluorophosphate LiPO2F2 0.5%, vinylene carbonate VC 0.7% and beta-sulfopropionic anhydride SPA 0.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com