Application of boric acid ester coalescing agent in preparation of water-based paint

A technology of film-forming aids and borate esters, which is applied in the field of water-based paint preparation, can solve the problems of lack of good construction performance and difficult paint film, and achieves the effects of great commercial value, relatively low cost, and simple synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

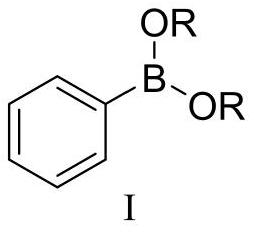

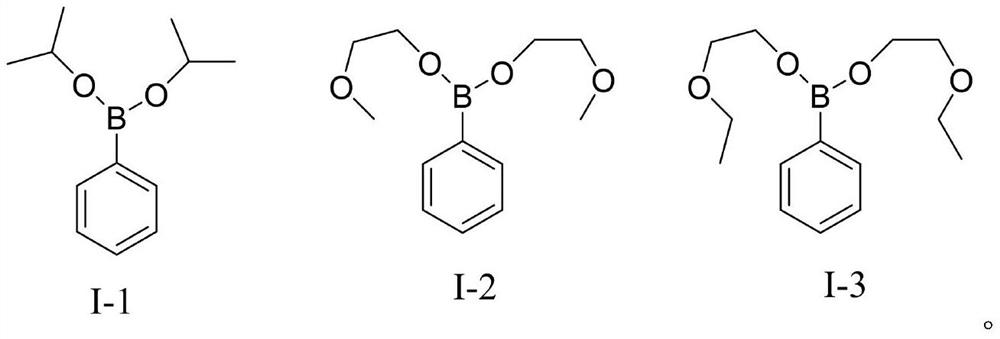

Image

Examples

Embodiment 1

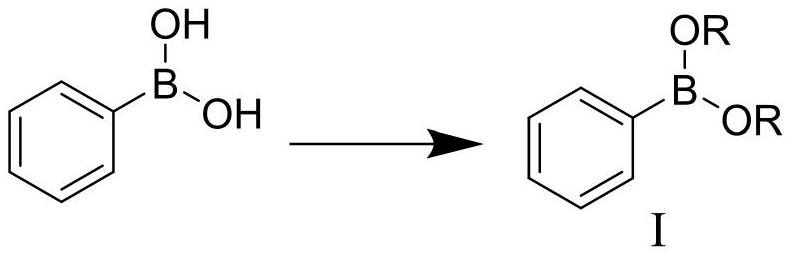

[0035] The preparation method of compound I-1:

[0036]

[0037] Mix phenylboronic acid and isopropanol with a molar ratio of 1:3, add catalyst anhydrous sodium sulfate that accounts for 0.1% by weight of the total amount of reactants, and place the above-mentioned substances in a four-wheeled container equipped with mechanical stirring, a condenser tube, and a thermometer. In an open flask, in the presence of an inert gas (such as nitrogen, etc.), the reaction system was slowly heated to 150°C, and kept under mechanical stirring for 5h at 150°C. After the reaction, the reaction solution was cooled to room temperature, filtered, and The clear liquid after suction filtration was transferred to a separatory funnel, and water was added for repeated extraction until the organic phase was neutral, and the organic phase was separated, and the organic phase was evaporated to remove low boilers to obtain a colorless and transparent compound I-1.

Embodiment 2

[0039] The preparation method of compound 1-2:

[0040]

[0041] Mix phenylboronic acid and ethylene glycol monomethyl ether with a molar ratio of 1:3, add catalyst anhydrous sodium sulfate that accounts for 0.1% by weight of the total amount of reactants, place the above-mentioned substances in a place equipped with mechanical stirring and a condenser, In a four-necked flask with a thermometer, in the presence of an inert gas (such as nitrogen, etc.), the reaction system was slowly heated to 150°C, and kept under mechanical stirring at 150°C for 5h. After the reaction, the reaction solution was cooled to room temperature, pumped After filtration, the clear liquid after suction filtration was transferred to a separatory funnel, water was added and extracted repeatedly until the organic phase was neutral, the organic phase was separated, and the organic phase was evaporated to remove low boilers to obtain a colorless and transparent compound I-2.

Embodiment 3

[0043] The preparation method of compound 1-3:

[0044]

[0045] Mix phenylboronic acid and ethylene glycol monoethyl ether with a molar ratio of 1:3, add catalyst anhydrous sodium sulfate that accounts for 0.1% by mass of the total amount of reactants, place the above-mentioned substances in a In a four-necked flask, in the presence of an inert gas (such as nitrogen, etc.), the reaction system was slowly heated to 150°C, and kept under mechanical stirring for 5 hours at 150°C. After the reaction was completed, the reaction solution was cooled to room temperature, and suction filtered , the clear liquid after suction filtration was transferred to a separatory funnel, water was added and extracted repeatedly until the organic phase was neutral, the organic phase was separated, and the organic phase was evaporated to remove low boilers to obtain a yellow transparent compound I-3.

[0046] The VOC test of the compound that embodiment 1~3 prepares:

[0047] The testing procedu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com