Condensable gaseous substance recycling method and condensable gaseous substance recycling system suitable for tail gas and exhaust gas

A gaseous substance and flue gas technology, applied in chemical instruments and methods, separation methods, steam condensation, etc., can solve the problems of large steam volume, waste, and lack, and achieve the effects of reducing pipeline systems, shortening transportation distance, and simplifying separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

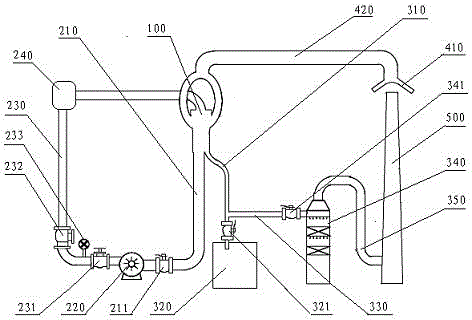

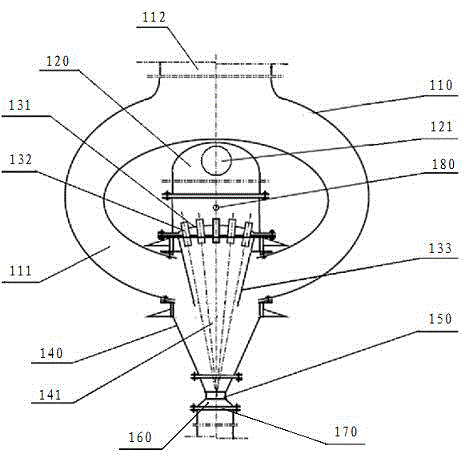

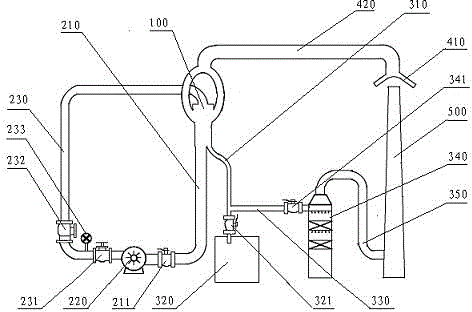

[0026] The recovery method of tail gas, steam component or other gaseous condensable substance components in industrial furnaces / towers that the present invention relates to passes through the gas collection hood above the tail gas discharge port or chimney, and the upper part of it is separated from smoke or dust. Naturally separated steam or other gaseous substances are introduced into the gas pipeline, and the steam from the gas pipeline is mixed with jet water through a liquid-gas mixer, or other gaseous substances are mixed with jets of other liquid fluids to convert steam into liquid water, and the Other gaseous substances are converted into other liquid fluids for recovery, and the liquid-gas mixer uses the negative pressure formed by liquid jets (water jets or other liquid jets) to suck the steam or other gaseous substances in the gas pipeline, and based on this as the The steam or other gaseous substances above the exhaust outlet or the chimney are drawn into the gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com