Lithium battery liquid injection head

A lithium battery injection, lithium battery technology, applied in battery pack parts, secondary battery gas removal, secondary battery repair/maintenance, etc., can solve the problem of low negative pressure rate, high injection volume, electrolyte waste, etc. problems, to achieve the effect of less component composition, high injection efficiency, and good injection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The lithium battery liquid injection head of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

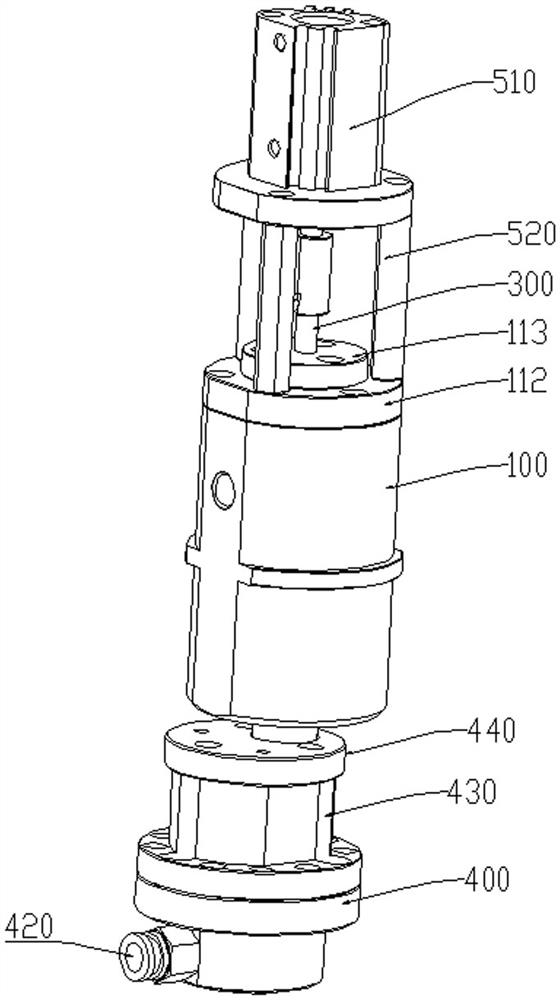

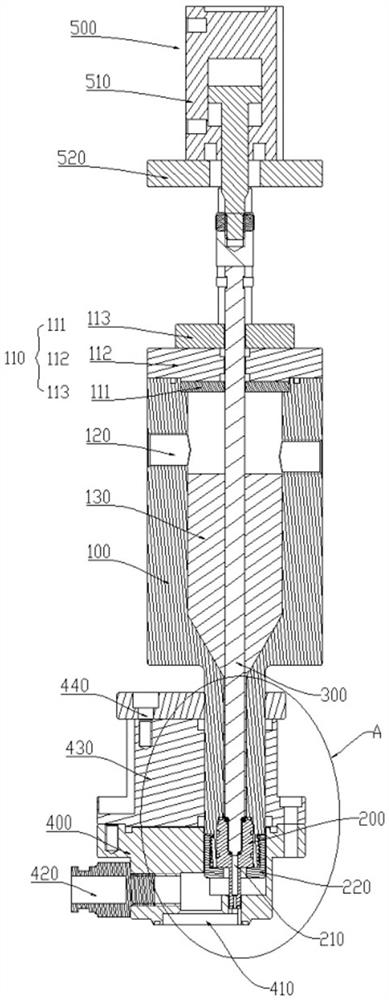

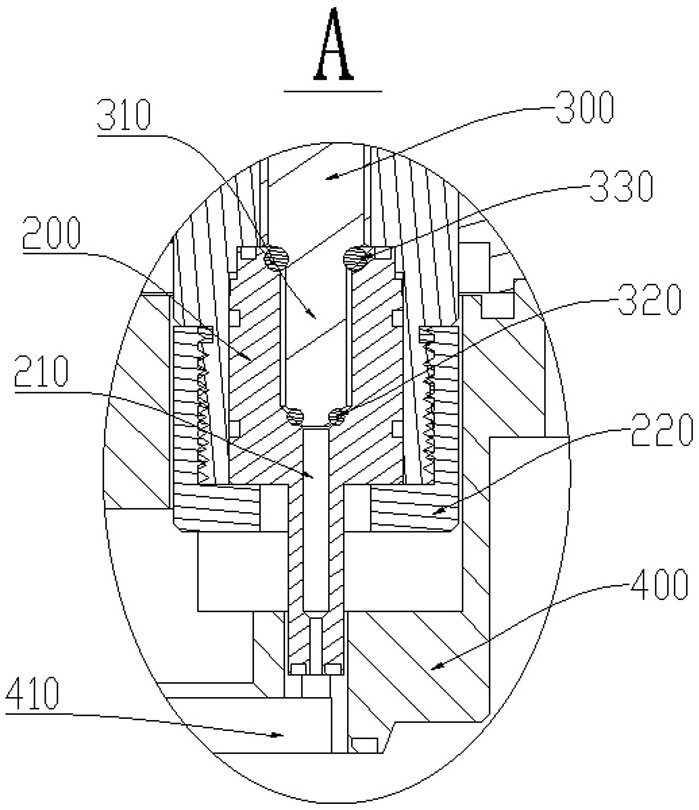

[0024] refer to Figure 1 to Figure 3 , a non-limiting embodiment of the present invention, a lithium battery liquid injection head, including a liquid injection cavity 100, one end of the liquid injection cavity 100 is a sealing end, the other end is a liquid injection end, and the inside of the liquid injection end Equipped with a liquid injection needle 200, the liquid injection needle 200 communicates with the liquid injection cavity 100, a vacuum cavity 400 is installed on the outside of the liquid injection end, and the outer end of the vacuum cavity 400 is provided with a lithium battery The battery tank 410 of the liquid injection needle 200 corresponds to the position of the liquid injection hole on the lithium battery, and the liquid injection needle 200 communicates with the vacuum c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com