Double clutch transmission

A dual-clutch and transmission technology, applied in vehicle gearboxes, transmissions, transportation and packaging, etc., can solve problems such as structural length extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

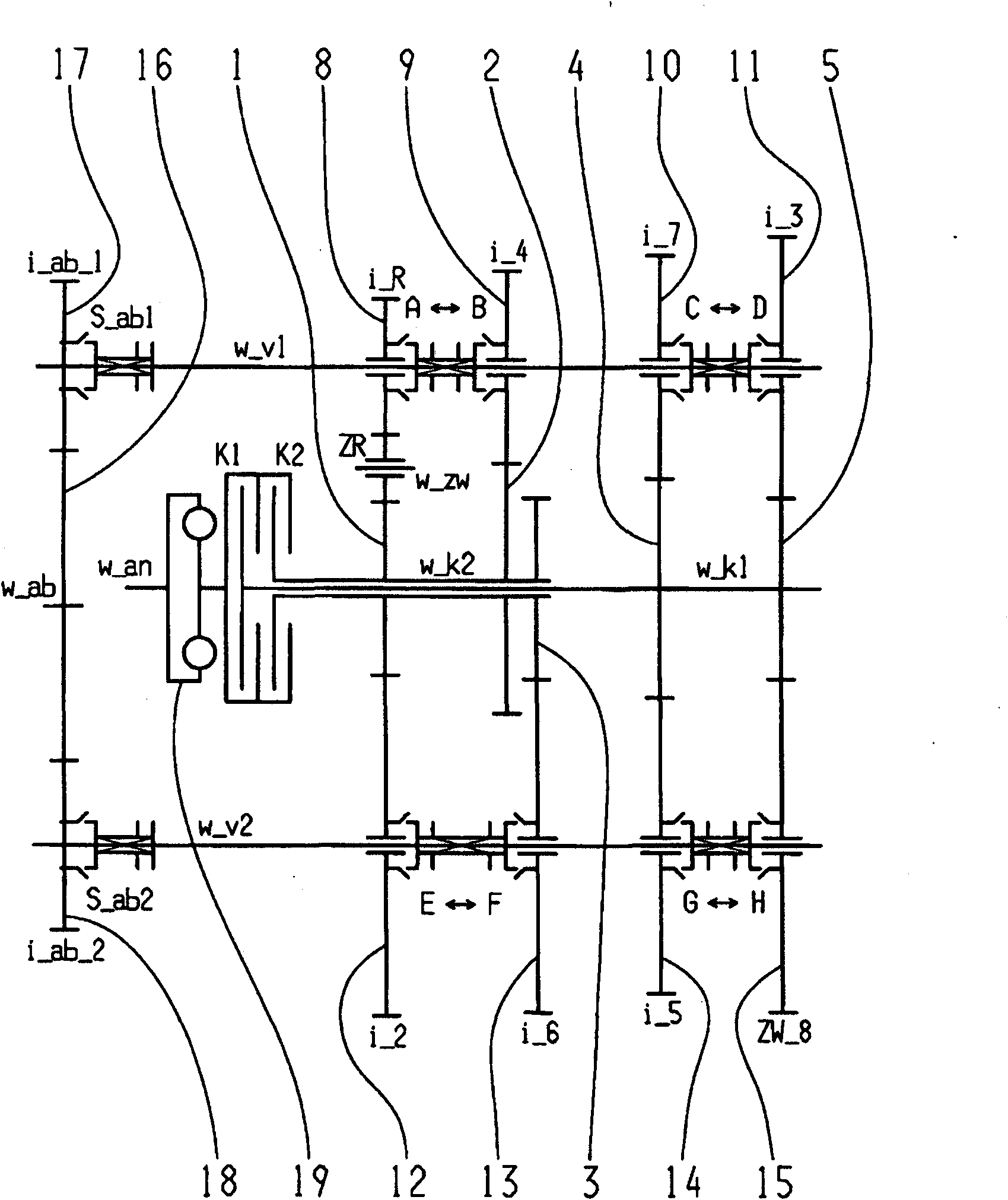

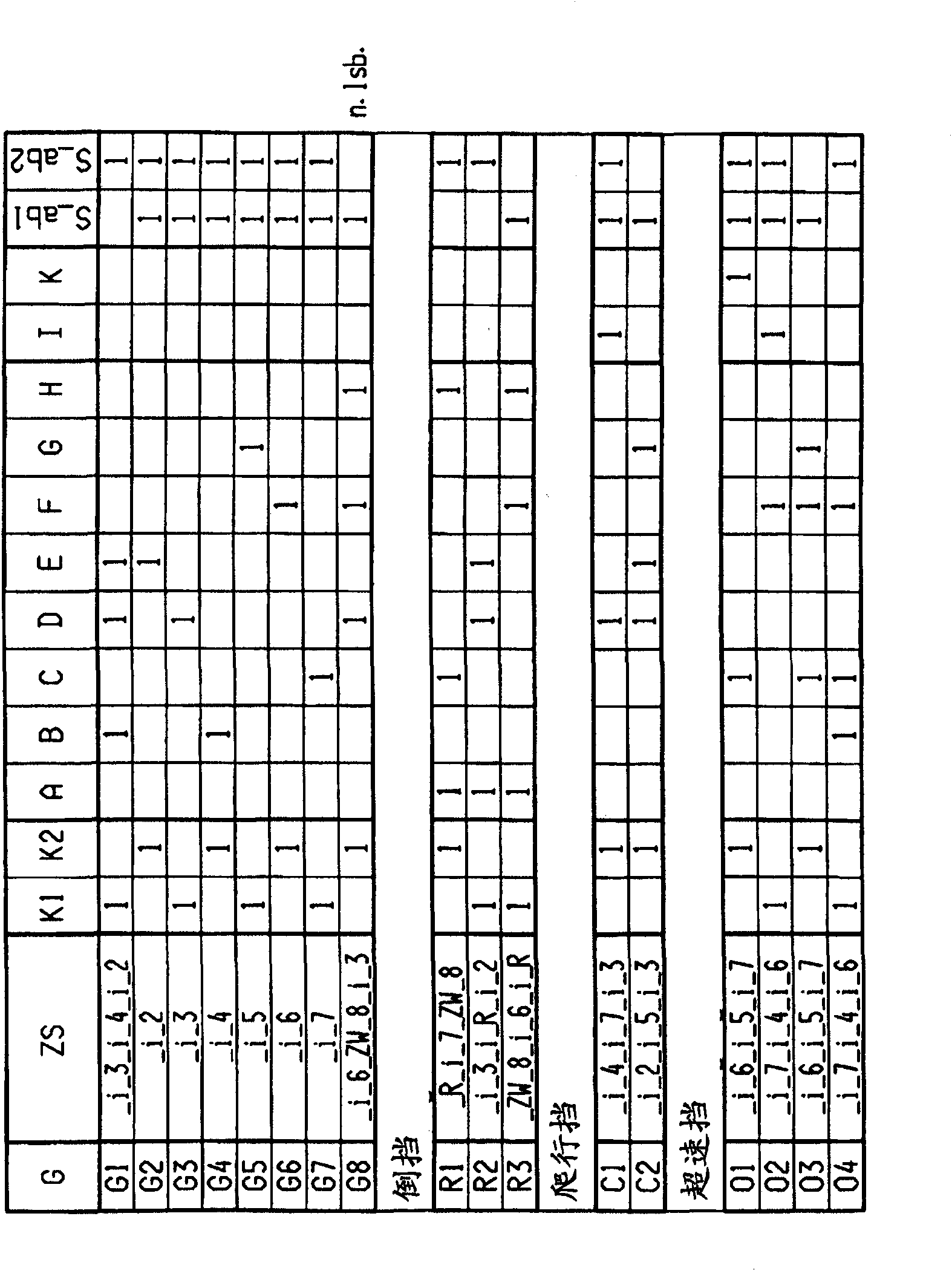

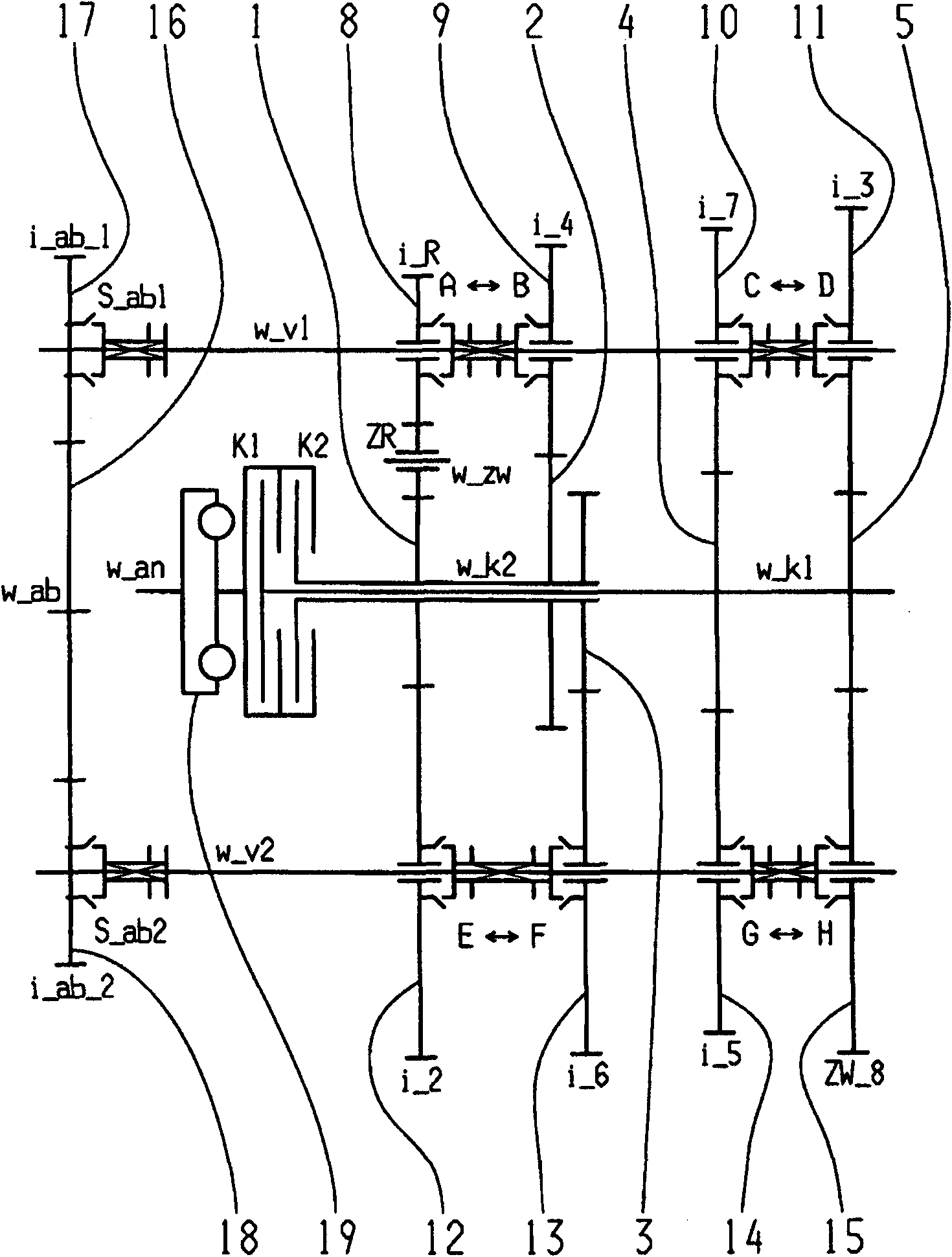

[0047] exist figure 1 , 3 , 5, 7, 9, 11 and 13 respectively show possible implementations of the eight-speed dual clutch transmission. The corresponding shift diagrams for different implementations are in figure 2 , 4 , 6, 8, 10, 12 and 14 are represented graphically.

[0048] The eight-speed dual-clutch transmission comprises two clutches K1, K2, the input side of which is connected to the drive shaft w_an and the output side of which is connected to one of two transmission input shafts w_k1, w_k2 arranged coaxially with each other. . Furthermore, a torsional vibration damper 19 can be arranged on the drive shaft w_an. In addition, two countershafts w_v1 , w_v2 are provided, on which gearwheels in the form of idler gears 8 , 9 , 10 , 11 , 12 , 13 , 14 , 15 are rotatably mounted. On the two transmission input shafts w_k1 , w_k2 , gearwheels in the form of fixed gearwheels 1 , 2 , 3 , 4 , 5 are arranged in a rotationally fixed manner, said fixed gearwheels being at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com