Novel sludge resource gradient utilization method

A technology of recycling and sludge, applied in the field of comprehensive utilization of resources, can solve the problems of low cost of use, achieve low cost of use, avoid equipment corrosion, and achieve good quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

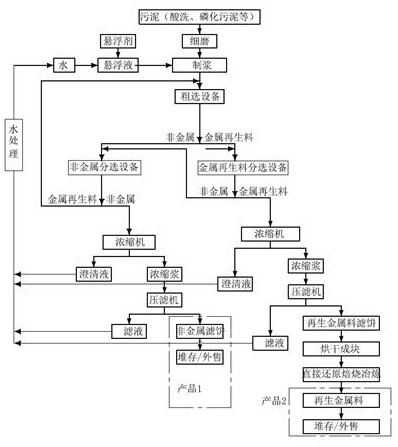

[0014] Such as figure 1 As shown, a new cascade utilization method of sludge resource utilization, which adopts a new processing method, can efficiently and thoroughly treat sludge in a cascade treatment method and step-by-step processing method, and can efficiently obtain recycled metal materials And silicate non-metallic materials, and can guarantee the quality of the separated recycled metal materials and silicate non-metallic materials, the whole process can complete the sludge treatment at a lower cost, compared with the traditional The processing cost is lower, the processing effect is better, the whole process is pollution-free, and the equipment can avoid problems such as equipment corrosion during transportation, so that the equipment has a longer service life and lower cost during processing. It includes: 1) finely grinding the sludge collected from the sludge, with a particle size of -100 mesh ≥ 75%. Through this step, the overall fine grinding of the sludge can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com