Underground optical fiber vortex-shedding flowmeter and underground flow measuring method

A vortex flowmeter and optical fiber technology, applied in the field of optical fiber vortex flowmeter and flow measurement, downhole optical fiber vortex flowmeter and downhole flow measurement, can solve the problems of low measurement accuracy, unusable, poor stability, etc., and achieve improvement The effect of sensitivity, accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

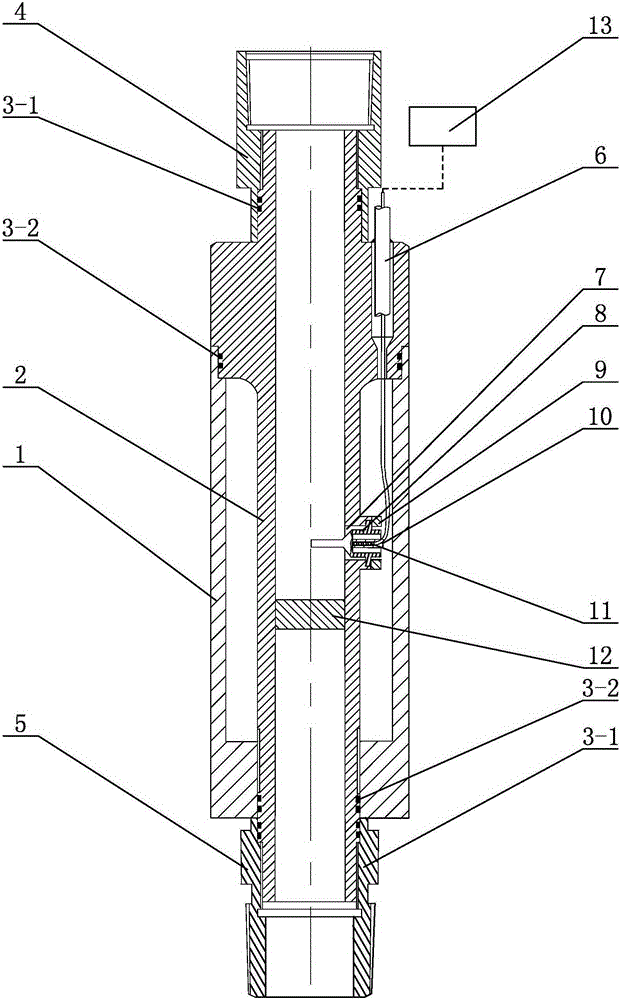

[0028] Specific implementation mode one: combine figure 1 Describe this embodiment, a downhole fiber optic vortex flowmeter described in this embodiment includes a fiber grating demodulator 13, and this embodiment also includes a housing 1, a central tube 2, an upper joint 4, a lower joint 5, and an armored optical cable 6. The probe 8, the pressure plate 9, the central axis 10, the fiber grating 11 and the vortex generator 12, the upper joint 4, the central tube 2, and the lower joint 5 are connected sequentially from top to bottom, and the shell 1 is set on the outer wall of the central tube 2 Above, the vortex generator 12 is arranged in the center tube 2, and the middle part of the outer wall of the center tube 2 has a through hole 7, the probe 8 is installed in the through hole 7 through the pressure plate 9, and the neutral axis 10 is inserted in the probe 8, The fiber grating 11 is arranged in the neutral axis 10 , one end of the armored optical cable 6 is connected to ...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 Describe this embodiment. The downhole fiber optic vortex flowmeter described in this embodiment also includes two first sealing rings 3-1 and two second sealing rings 3-2. Two first sealing rings 3-1 are provided, and two second sealing rings 3-2 are provided at the connection between the lower joint 5 and the lower end of the housing 1 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the cross-section of the vortex generator 12 of a downhole fiber optic vortex flowmeter in this embodiment is a polygon with three corners removed from an isosceles triangle, and the vortex generator 12 is made of 316L stainless steel.

[0031] In this embodiment, the bottom surface of the triangular column of the vortex street generating body 12 is the upstream surface, and the vertical bisector of the upstream surface is in the same plane as the flat part of the probe. The vortex street generating body 12 plays the role of generating and separating the vortex, and the triangular column structure The vortex signal generated by the vortex generator 12 is both strong and stable, and can also reduce other disturbances and noises of the fluid. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com