Binary oil displacement system containing bio-based surfactant and biopolymer and application of binary oil displacement system

A technology of biopolymers and surfactants, applied in the preparation of organic compounds, drilling compositions, chemical instruments and methods, etc., can solve the problems of not being able to fundamentally change the effect of reservoir development and not involving crude oil, etc. Anti-Ca2+ properties, viscosifying and reducing interfacial tension, widening application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Further, the preparation method of biopolymer HS-EPS comprises the following steps:

[0039] 1) Inoculate the Aminomonas strain into the seed medium, and vibrate at 30±5°C for 18±2 hours to obtain the seed liquid;

[0040] Among them, the seed medium includes the following components and mass concentrations: sucrose 30±2g / L, peptone 3±1g / L, K 2 HPO 4 1±0.5g / L, MgSO 4 0.2±0.1g / L, KCl 0.5±0.2g / L, CaCl 2 0.2±0.1g / L;

[0041] 2) Inoculate the seed liquid into the fermentation medium with an inoculation amount of 5 ± 1%, and obtain the fermentation liquid after vibrating at 30 ± 5°C for 72 ± 6 hours;

[0042] Among them, the fermentation medium includes the following components and mass concentrations: maltose 40±2g / L, yeast powder 5±1g / L, K 2 HPO 4 5±1g / L, MgSO 4 0.5±0.2g / L, KCl 2±1g / L, CaCl 2 0.2±0.1g / L;

[0043] 3) Mix the fermented liquid with (2-6) times the volume of 95% ethanol aqueous solution, and let it stand at 4±1°C for 12±2h, after centrifugation, r...

Embodiment 1

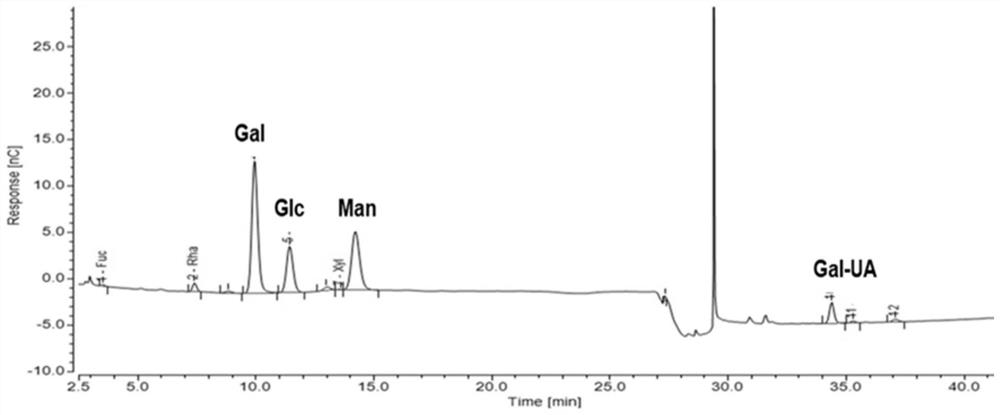

[0053] A kind of biopolymer HS-EPS, its preparation method comprises the following steps:

[0054] 1) In the ultra-clean bench, inoculate the Sphingomonas sp.HS strain preserved on the slope into the seed medium with an inoculation loop, and then vibrate at 30°C and 150rpm for 18 hours to obtain the seed solution;

[0055] Wherein, the seed culture medium includes the following components and mass concentrations: sucrose 30g / L, peptone 3g / L, K 2 HPO 4 1g / L, MgSO 4 0.2g / L, KCl 0.5g / L, CaCl 2 0.2g / L, pH≈7.5; Seed medium filling volume: 50mL (250mL container);

[0056] 2) In the ultra-clean bench, inoculate the seed liquid into the fermentation medium with an inoculum amount of 5%, and then vibrate at 30°C and 180rpm for 72h to obtain the fermentation liquid;

[0057] Wherein, the fermentation medium includes the following components and mass concentrations: maltose 40g / L, yeast powder 5g / L, K 2 HPO 4 5g / L, MgSO 4 0.5g / L, KCl 2g / L, CaCl 2 0.2g / L; Fermentation medium ...

Embodiment 2

[0062] A binary oil displacement system, the preparation method comprising:

[0063] Using Daqing simulated formation water as base fluid, prepare 6.0g / L surfactant mother liquor and 9.0g / L biopolymer mother liquor, then mix surfactant mother liquor, biopolymer mother liquor, and Daqing simulated formation water to obtain biological A binary flooding system with a polymer concentration of 3.0 g / L and a surfactant concentration of 0.5 g / L, and a binary flooding system with a biopolymer concentration of 3.0 g / L and a surfactant concentration of 3.0 g / L system.

[0064] Among them, the Daqing simulated formation water includes the following components and mass fractions: NaCl 1588.3mg / L, CaCl 2 112.2mg / L, MgCl 2 42.9mg / L, Na 2 SO 4 17.1mg / L, NaHCO 3 3176.0mg / L, Na 2 CO 3 381.6mg / L.

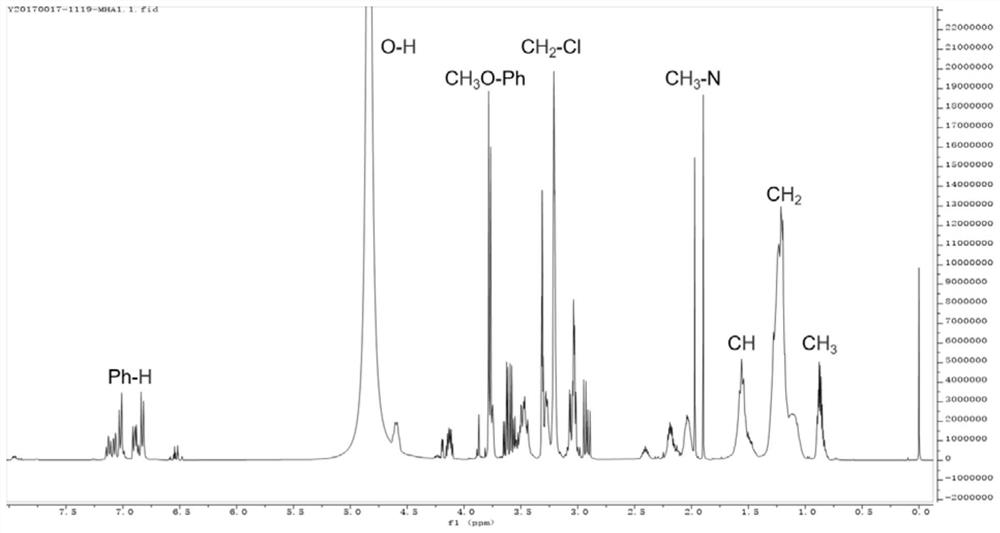

[0065] Wherein, in the biopolymer mother liquor, the biopolymer used is the biopolymer HS-EPS prepared in Example 1; in the surfactant mother liquor, the surfactant used is the benzyloxy-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com