Method for producing biodiesel by utilizing immobilized lipase and adopting static emulsion method

A technology of immobilized lipase and biodiesel, which is applied in the fields of immobilized on/in organic carriers, biofuel, chemical industry, etc., can solve the problems of poor activity of free lipase, difficult recovery of esterification products, high cost, etc. Achieve good mechanical stability, easy recycling and good swelling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

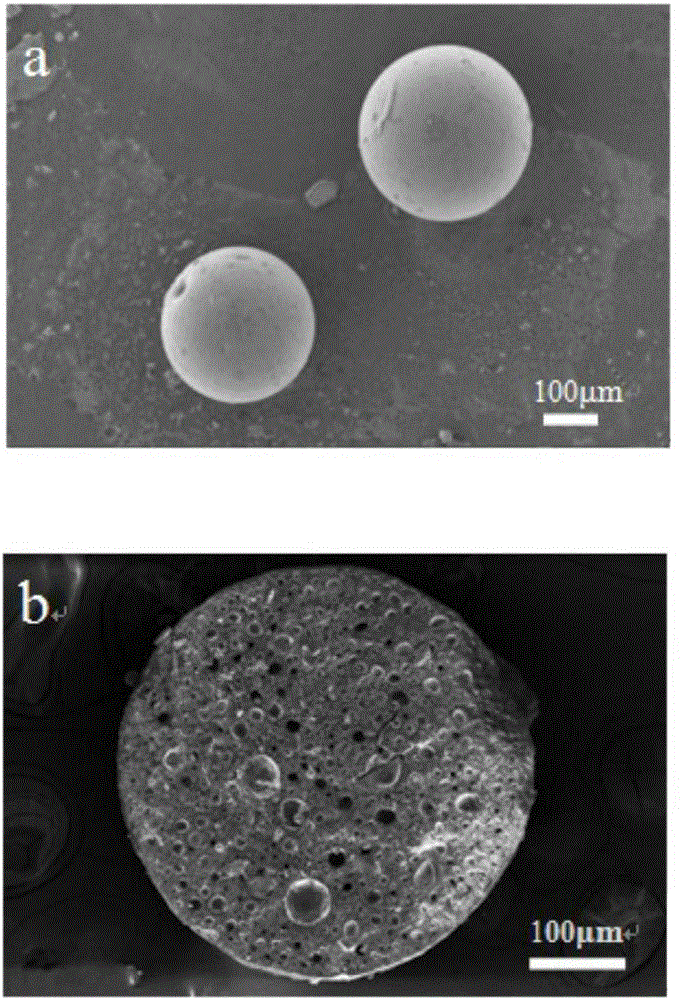

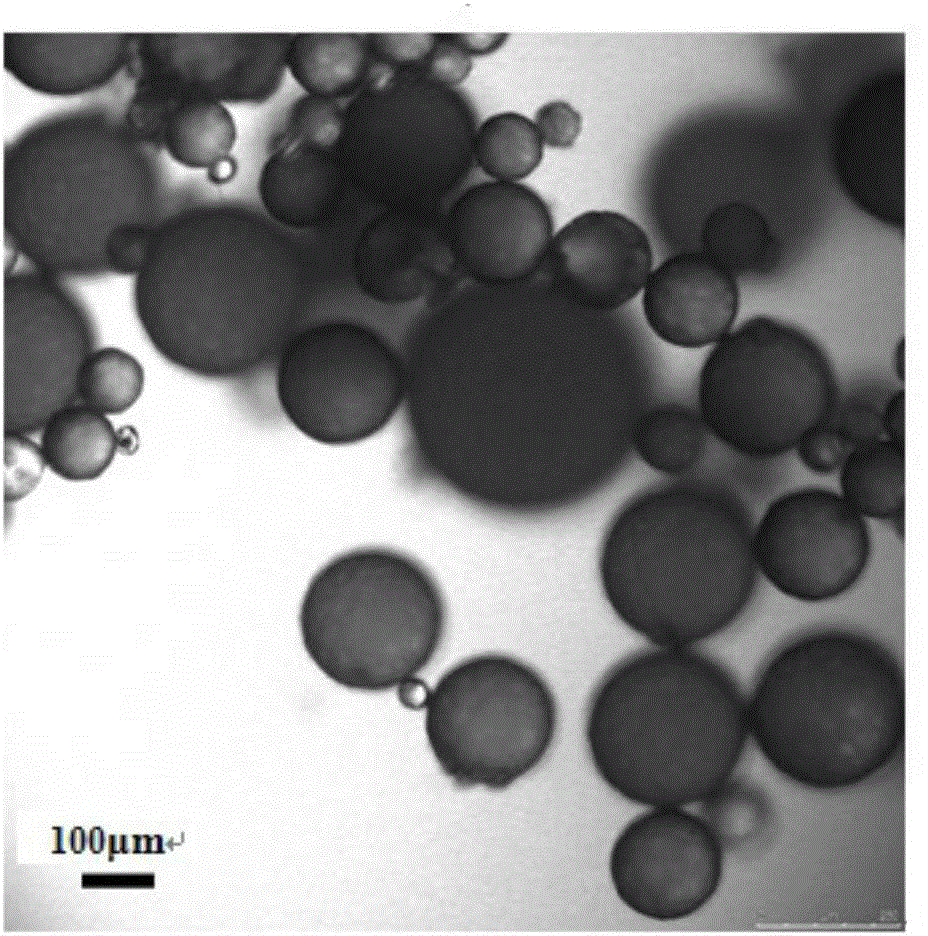

[0038] Immobilized lipase: Candida antarctica lipase B was dissolved in phosphate buffered saline solution of pH 7.0, configured into a 20 mg / mL lipase solution, polydimethylsiloxane (Dow Corning DC184, the same as in the following examples) This) 2g, (volume 1.9mL), lipase liquid 0.5g, platinum catalyst 4g join in the Erlenmeyer flask, vacuumize (0.09Mpa) magnetic stirring 0.5 hour, form emulsion; In Erlenmeyer flask, add dispersion agent PVA ( The degree of polymerization is 1000, the degree of alcoholysis is 98%; the following examples are the same as this) solution 200mL, magnetically stirred for 0.5 hour to make the PVA solution evenly adsorbed on the surface of the oil droplet to form a composite emulsion. Place the Erlenmeyer flask containing the complex emulsion in a constant temperature water bath, mechanically stir at 30°C, solidify for 3 hours, and use a water circulation vacuum pump to filter and separate the immobilized enzyme from the system to obtain the immobili...

example 2

[0044] Immobilized lipase: Dissolve Burkholderia cepacia lipase in phosphate buffered saline solution with pH 7.0 to prepare 40 mg / mL enzyme solution, add 2 g of polydimethylsiloxane (volume 1.9 mL), fat Enzyme liquid 1g, platinum catalyst 1g join in the Erlenmeyer flask, vacuumize (0.09Mpa) magnetic stirring and stirring for 1 hour, form emulsion; Add dispersant PVP solution 300mL in Erlenmeyer flask, magnetic stirring 0.5 hour makes PVP (K value 30; the following examples are the same) the solution is evenly adsorbed on the surface of the oil droplet to form a composite emulsion. Place the Erlenmeyer flask containing the complex emulsion in a constant temperature water bath, mechanically stir at 40°C, solidify for 1 hour, and use a water circulation vacuum pump to filter and separate the immobilized enzyme from the system to obtain the immobilized lipase;

[0045] Preparation of biodiesel: 0.60g of peanut oil (the volume of peanut oil is 0.63mL, and the molar weight is 0.67m...

example 3

[0048] Immobilized lipase: Dissolve Candida columnar lipase in phosphate buffered saline solution with pH 7.0 to make 50mg / mL enzyme solution, add polydimethylsiloxane 2g (volume 1.9mL), lipase solution Add 0.2g and 5g of platinum catalyst into the Erlenmeyer flask, vacuumize (0.09Mpa) and magnetically stir for 0.5 hours to form an emulsion; add 300mL of dispersant PVA solution to the Erlenmeyer flask, and magnetically stir for 1 hour to make the PVA solution evenly adsorbed on the oil Drops on the surface to form a complex emulsion. Place the Erlenmeyer flask containing the complex emulsion in a constant temperature water bath, mechanically stir at 60°C, solidify for 1 hour, and use a water circulation vacuum pump to filter and separate the immobilized enzyme from the system to obtain the immobilized lipase;

[0049] Preparation of biodiesel: jatropha oil 0.60g (jatropha oil volume is 0.6mL, molar weight is 0.66mmol), methanol 0.24g, (methanol volume is 0.30mL; molar weight i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com