Polymer-graphene-polyaniline electromagnetic shielding composite material and preparation method thereof

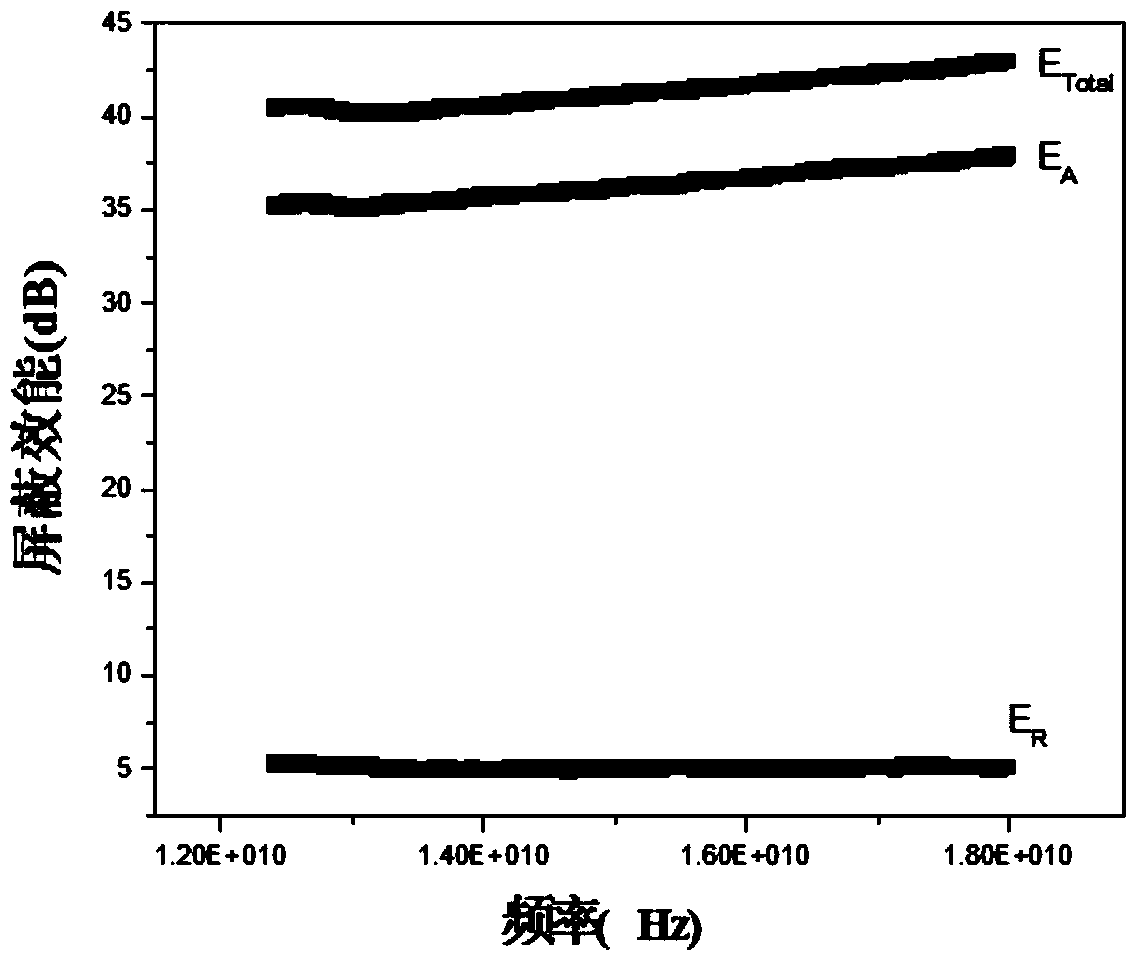

A graphene composite, electromagnetic shielding technology, applied in the field of functional polymer materials, can solve the problems of narrow shielding band, affecting the overall performance of composite materials, poor shielding effectiveness, etc., achieving excellent conductivity and electromagnetic shielding performance, and adjustable electromagnetic shielding effectiveness. Controllable and easy to process and form the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The polymer-graphene-polyaniline electromagnetic shielding composite material of this embodiment is mainly made of the following raw materials in weight percentage: 5% polyurethane, 15% modified expanded graphite, 10% aniline, N-phenyl maleamide 3% lanthanum (III) acid radical, 2% stearic acid, and the balance is polyvinyl chloride; the modified expanded graphite is after interface treatment with a titanate coupling agent (such as NDZ-311 or NTC-131, etc.) Expanded graphite, the mass of titanate coupling agent is 4% of the mass of expanded graphite, and the interface treatment time is 15min. Expanded graphite is made of expandable graphite with an expansion ratio higher than 220 and expanded by microwave irradiation for 8s.

[0040] The preparation method of the polymer-graphene-polyaniline electromagnetic shielding composite material of the present embodiment comprises the following steps:

[0041] Step 1. Mix polyvinyl chloride, polyurethane, N-phenylmaleamatolanthanu...

Embodiment 2

[0049] The polymer-graphene-polyaniline electromagnetic shielding composite material of this embodiment is mainly made of the following raw materials in percentage by weight: chlorinated polyethylene 10%, modified expanded graphite 15%, aniline 5%, and the balance is poly Propylene; the modified expanded graphite is expanded graphite after interface treatment with a titanate coupling agent (such as NDZ-311 or NTC-131, etc.), and the quality of the titanate coupling agent is 3% of the expanded graphite quality, The interface treatment time is 20 minutes, and the expanded graphite is made of expandable graphite with an expansion ratio higher than 220, which is expanded by microwave irradiation for 15 seconds.

[0050] The preparation method of the polymer-graphene-polyaniline electromagnetic shielding composite material of the present embodiment comprises the following steps:

[0051] Step 1. After uniformly mixing polypropylene and chlorinated polyethylene, use a disc-shaped me...

Embodiment 3

[0058] The polymer-graphene-polyaniline electromagnetic shielding composite material of this embodiment is mainly made of the following raw materials in weight percentage: 8% polyurethane, 10% modified expanded graphite, 20% aniline, and the balance is polycarbonate; The modified expanded graphite is expanded graphite after interface treatment with a titanate coupling agent (such as NDZ-311 or NTC-131, etc.), the quality of the titanate coupling agent is 5% of the expanded graphite mass, and the interface treatment The time is 10 minutes, and the expanded graphite is made of expandable graphite with an expansion ratio higher than 220, which is expanded by microwave irradiation for 3s.

[0059] The preparation method of the polymer-graphene-polyaniline electromagnetic shielding composite material of the present embodiment comprises the following steps:

[0060] Step 1. After uniformly mixing polycarbonate and polyurethane, use a disc-shaped mechanochemical reactor to grind for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com