A conformal cooling channel with hydrophobic effect and its manufacturing method

A technology of conformal cooling and hydrophobic effect, which is applied in the field of mold manufacturing, can solve the problems of easy corrosion of surface metal, easy blockage of conformal cooling channels, and low cooling efficiency of the mold cooling system, so as to avoid blockage of cooling channels and avoid metal The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

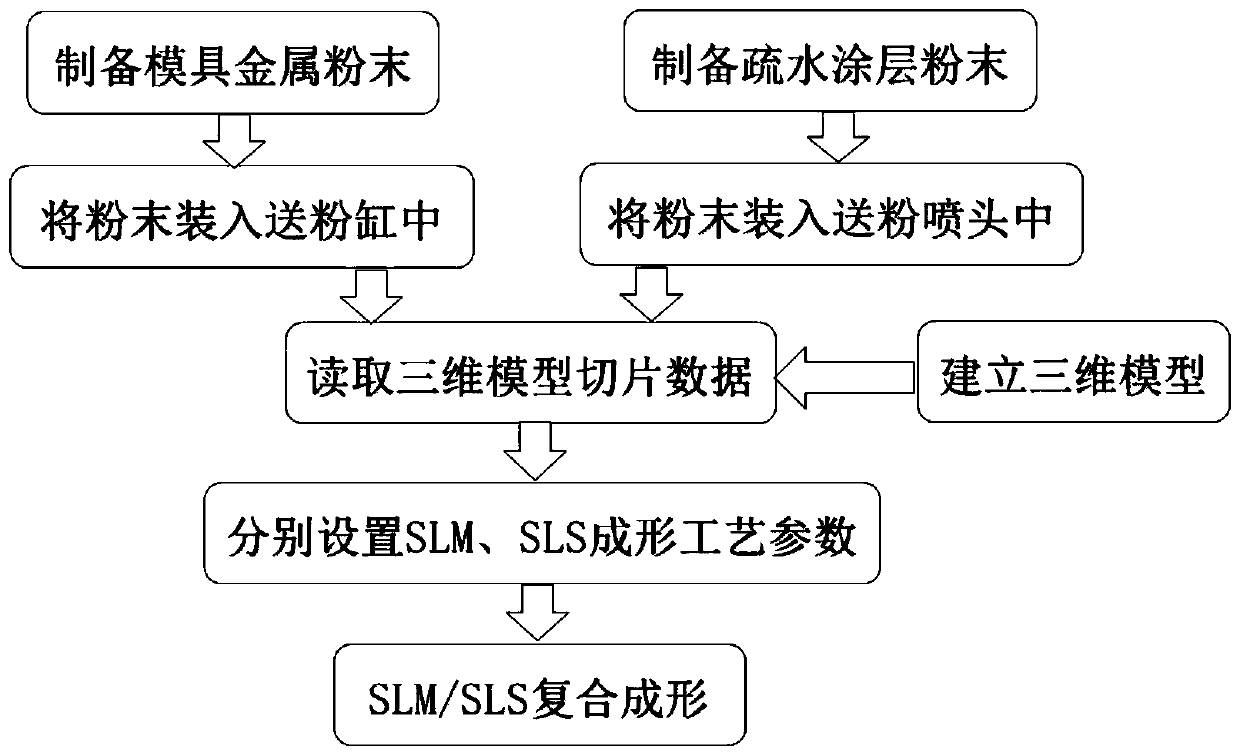

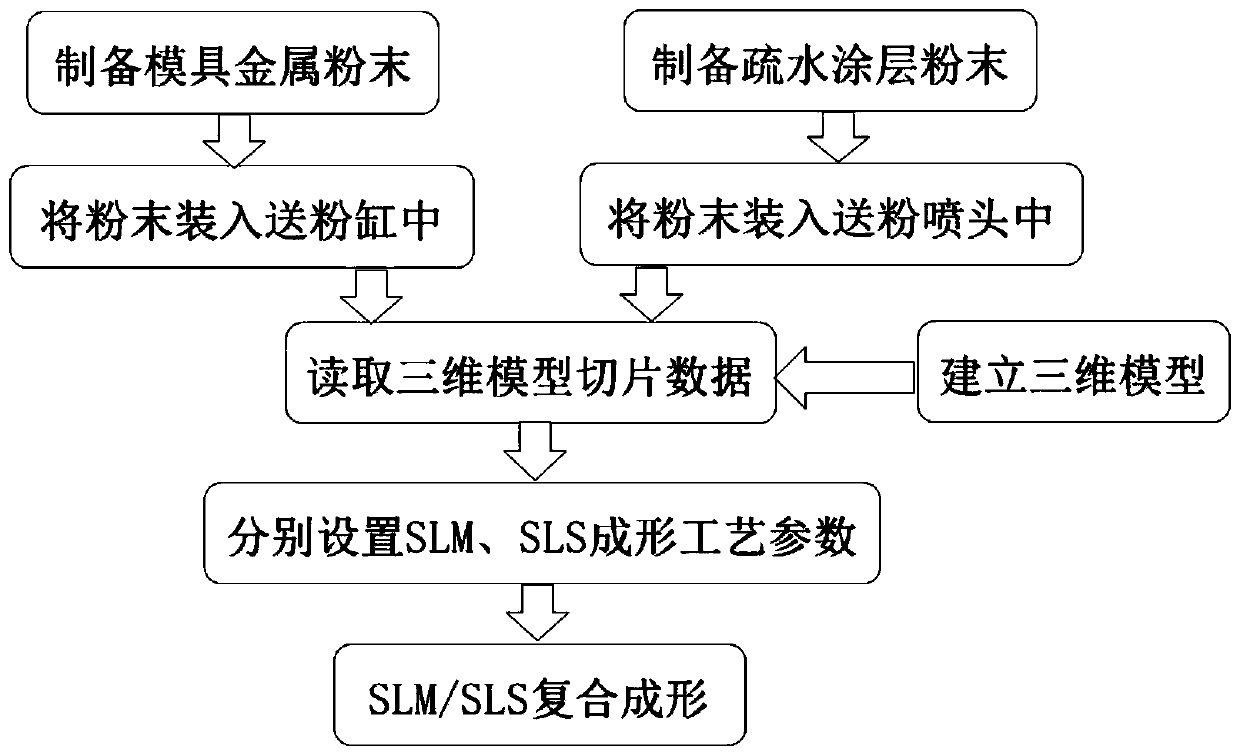

[0035] This embodiment comprises the following steps:

[0036] (1) the monodisperse positively charged polymethyl propylene methyl ester (PMMA) microsphere of 20 microns is prepared by dispersion polymerization method, adds water and dilutes to solid content 10%, adds 5% particle diameter again and is 50 Nano-siloxane modified silica sol (SiO 2 ), stirred at 80°C for 20 hours to obtain PMMA / SiO 2 Complex emulsion. Take 5g of polycarbonate plastic flow enhancer, 5g of acrylate adhesive, 0.2g of dispersant and PMMA / SiO2 composite emulsion and mix thoroughly, stir at room temperature for 2 hours, then separate, wash, and bake the product in an oven at 70°C After drying for 100 hours, the hydrophobic PMMA / SiO2 micro-nano structure composite powder can be obtained;

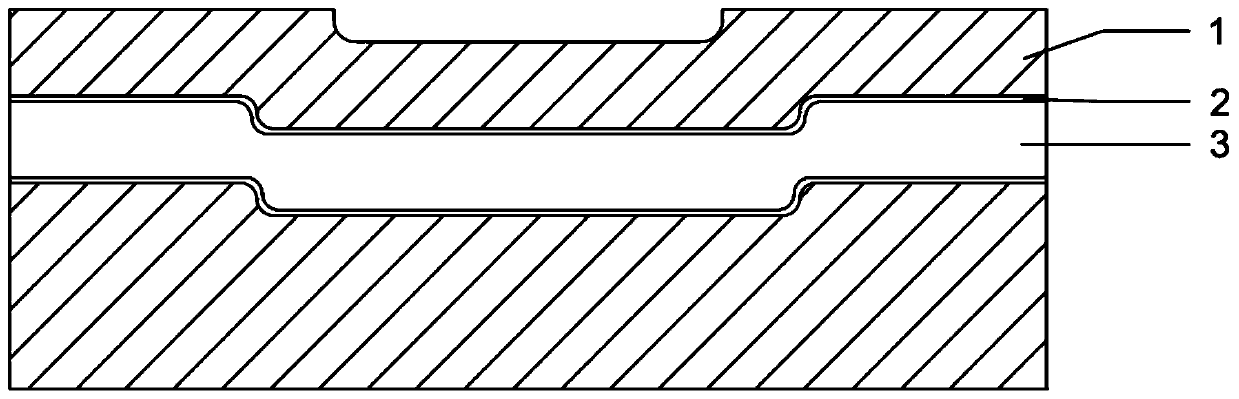

[0037] (2) Use 3D design software to design such as figure 2 The 3D model of the conformal cooling channel in , where 1 is the mold metal, 2 is the hydrophobic coating, and 3 is the conformal cooling channel. Imp...

Embodiment 2

[0043] This embodiment comprises the following steps:

[0044] (1) the monodisperse positively charged polymethyl propylene methyl ester (PMMA) microsphere of 20 microns is prepared by dispersion polymerization method, adds water and dilutes to solid content 10%, adds 5% particle diameter again and is 50 Nano-siloxane modified silica sol (SiO 2 ), stirred at 80°C for 15 hours to obtain PMMA / SiO 2 Complex emulsion. Take 5g of polycarbonate plastic flow enhancer, 5g of acrylate adhesive, 0.2g of dispersant and PMMA / SiO2 composite emulsion and mix thoroughly, stir at room temperature for 2 hours, separate, wash, and dry the product in an oven at 70°C 80 hours. Hydrophobic PMMA / SiO can be obtained 2 Micro-nano structure composite powder;

[0045] (2) Use 3D design software to design such as figure 2 The 3D model of the conformal cooling channel in , where 1 is the mold metal, 2 is the hydrophobic coating, and 3 is the conformal cooling channel. Import the 3D model into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com