Synthesis method of cerium-zirconium oxide nanomaterial dispersed in aqueous medium

A technology of cerium-zirconium oxide and nanomaterials, which is applied in the field of synthesis of rare earth cerium-based oxide nanomaterials, can solve the problems of monodispersion of nanoparticles, and achieve the effect of low synthesis cost and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

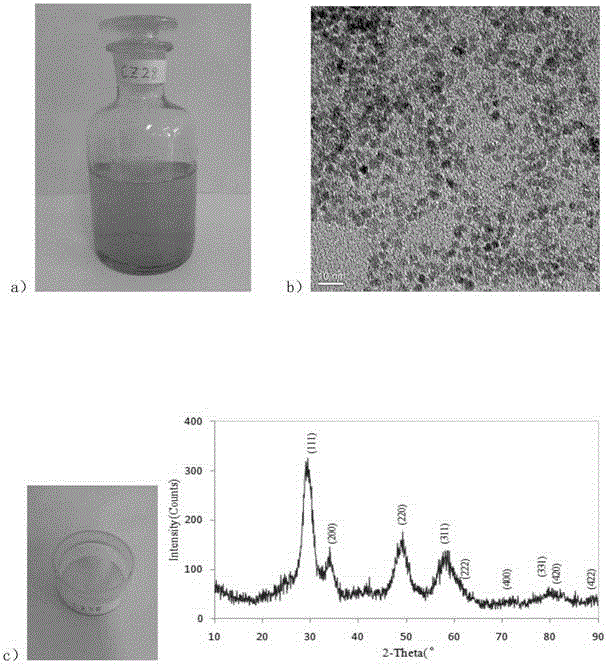

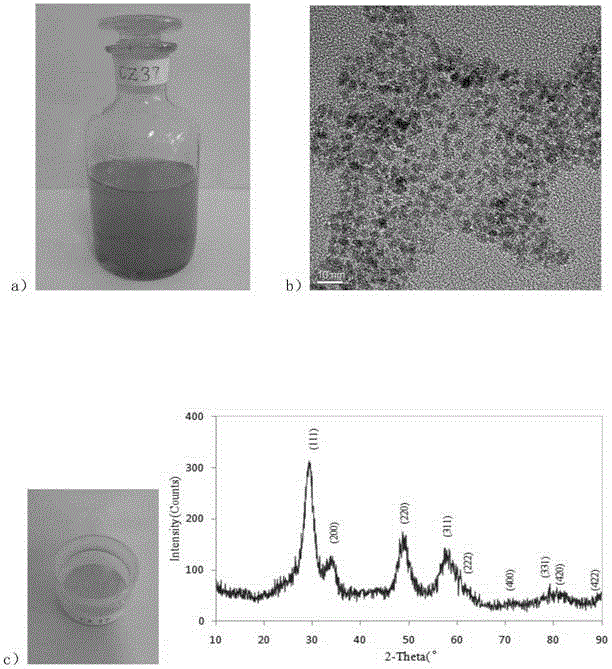

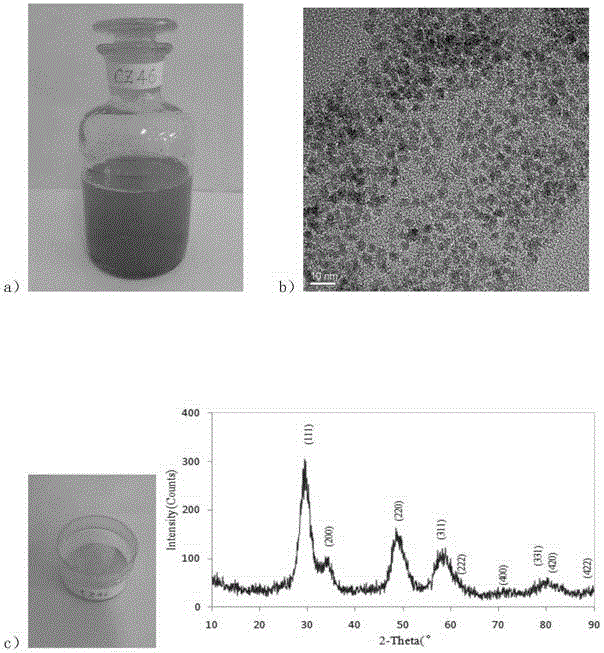

[0055] Aqueous medium dispersed cerium zirconium oxide nanomaterials are sols with water as the dispersion medium and solid solution nanoparticles composed of cerium oxide and zirconia as the dispersed phase. The nanoparticles are single crystals with a nanometer size of 2-8nm. The medium is monodisperse; solid solution nanoparticles composed of ceria and zirconia are also called cerium-zirconium oxide nanoparticles, and the general formula is denoted as Ce x Zr 1-x o 2 , x=0.2~0.8, represents the mass fraction of Ce; Ce x Zr 1-x o 2The mass (w / g) of the mass (w / g) accounts for 5-10% of the sol body volume (V / ml); the synthesis method of the aqueous medium dispersion cerium zirconium oxide nanomaterial comprises the following steps: (1) using Ce and Zr inorganic Precipitation reaction between salt aqueous solution and inorganic alkali aqueous solution to prepare Ce-Zr mixed hydroxide precipitate; (2) heating Ce-Zr mixed hydroxide precipitate to reflux to prepare Ce-Zr hydr...

Embodiment 1

[0106] Dispersion of cerium zirconium oxide Ce in water medium 0.2 Zr 0.8 o 2 Synthesis of Nanomaterials:

[0107] Take 0.010molCe(NO 3 ) 3 ·6H 2 O was added to deionized water and stirred to dissolve, and 0.040mol Zr(NO 3 ) 4 ·5H 2 Add O into deionized water and stir to dissolve, mix cerium and zirconium salt solutions and add 0.61ml of hydrogen peroxide (30w%), dilute to 80ml with deionized water, and record it as liquid A; take 7.49ml of concentrated ammonia water (25w%), 9.60 Add 1 g of ammonium carbonate to deionized water to form an alkaline solution, dilute to 80 ml with deionized water, and record it as liquid B. Stir the liquid A and heat it to 60° C., drop the liquid B into the liquid A until the pH of the liquid A is 8.3-8.5, and obtain a Ce-Zr mixed hydroxide precipitate suspension. Stir the suspension at 80°C for 2h, add 40ml of ethylene glycol, use a reflux device to reflux at a heating temperature of 105°C with stirring for 2h, and cool to room temperat...

Embodiment 2

[0110] Dispersion of cerium zirconium oxide Ce in water medium 0.3 Zr 0.7 o 2 Synthesis of nanomaterials:

[0111] Take 0.012molCe(NO 3 ) 3 ·6H 2 O was added to deionized water and stirred to dissolve, and 0.028mol ZrOCO 3 ·nH 2O (dissolved with nitric acid first) was added to deionized water and stirred to dissolve, mixed with cerium and zirconium salt solution, diluted to 80ml with deionized water, and recorded as solution A; take 3.32ml of concentrated ammonia water (25w%) and 1.77g of sodium hydroxide to add Make an alkaline solution in deionized water, add 0.73ml of hydrogen peroxide (30w%), dilute to 80ml with deionized water, and record it as solution B. Drop liquid A into liquid B under stirring, and adjust the pH to 8.5-8.8 with dilute ammonia water after dripping of liquid A to obtain Ce-Zr mixed hydroxide precipitate suspension. Let the suspension stand overnight, add 20ml of ethanol and 20ml of isopropanol, reflux at a heating temperature of 85°C with stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com