Preparation method of nanometer tungsten trioxide crystallite

A technology of nano-tungsten trioxide and microcrystals, applied in chemical instruments and methods, tungsten oxide/tungsten hydroxide, crystal growth, etc., can solve problems such as complex process, achieve short process flow, continuous and stable operation, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

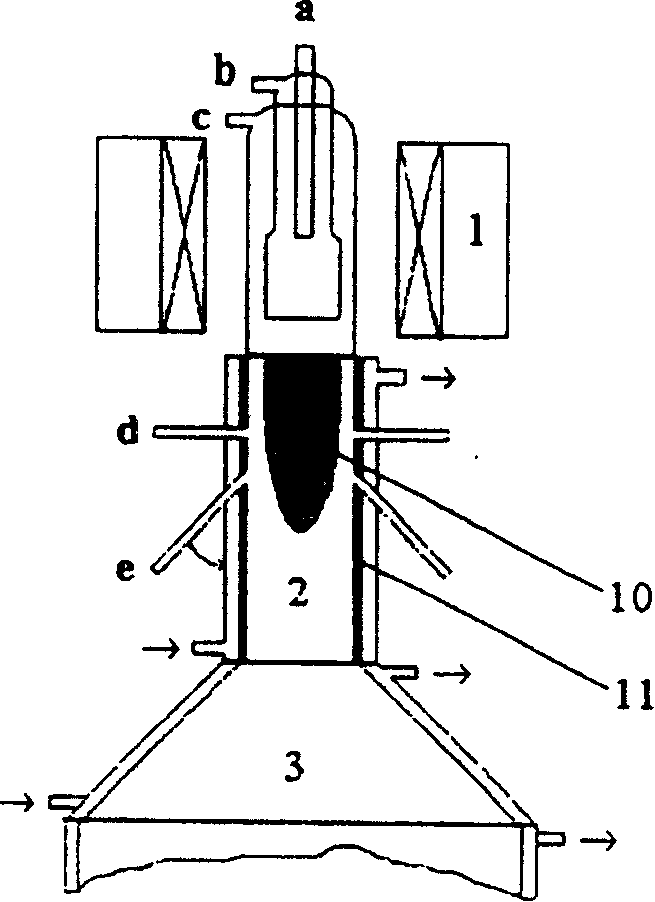

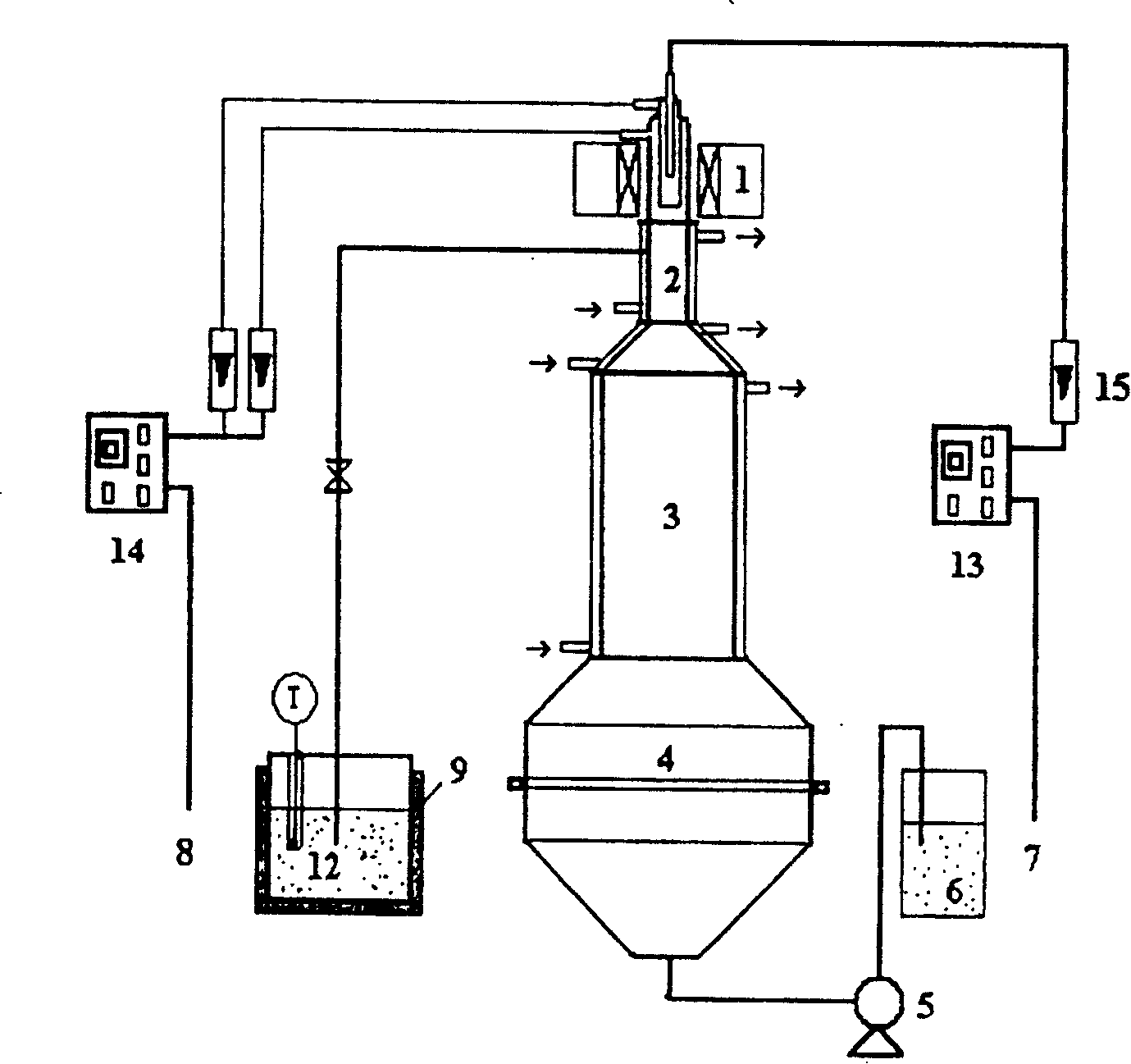

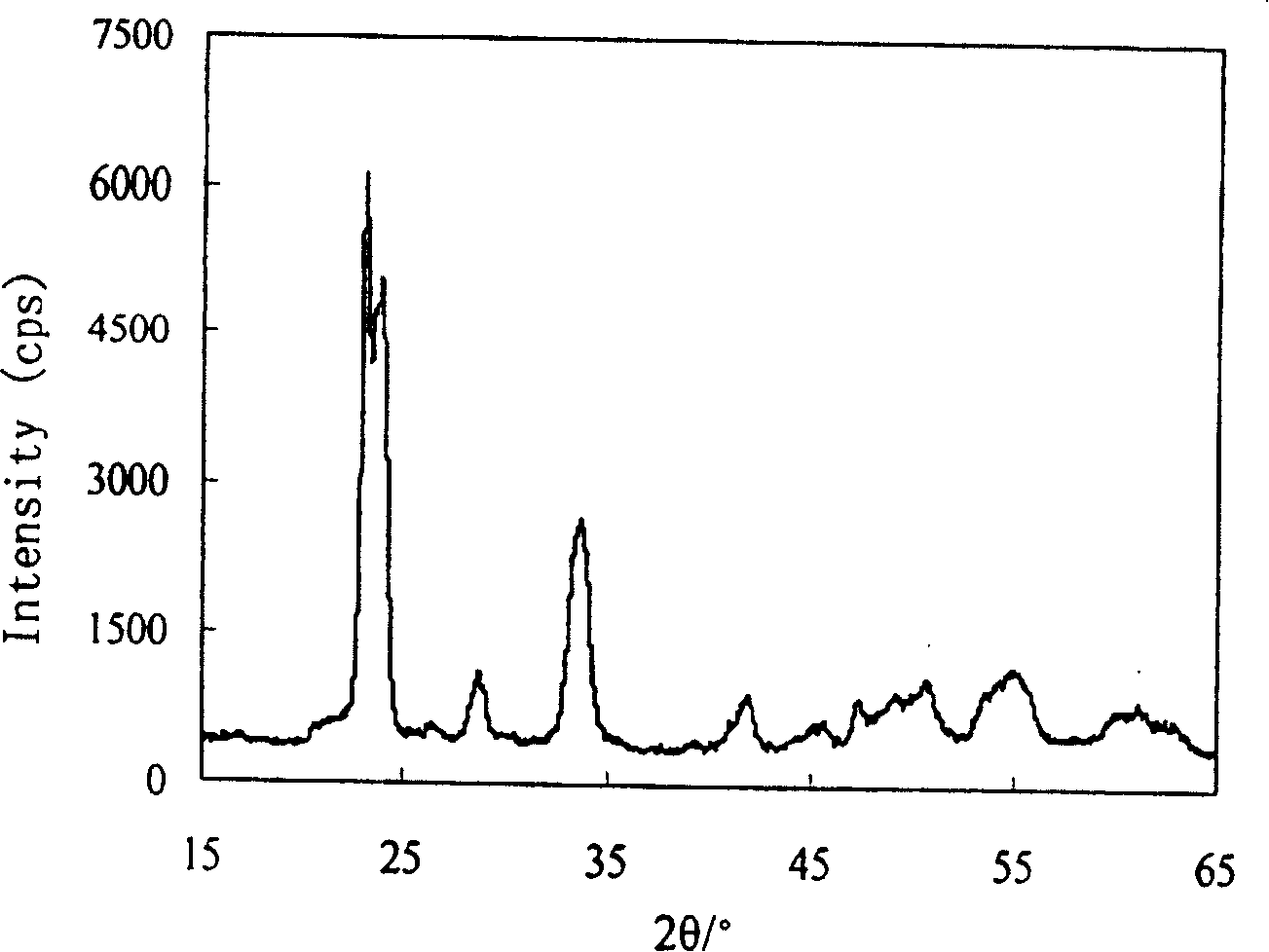

[0028]Tungsten chloride is used as the basic raw material. The power of the high-frequency plasma generator 1 is 2.5KW; the inner diameter of the high-frequency plasma reactor 2 is 20mm, and the ratio of the length to the inner diameter is 4:1; the inner diameter of the cooler 3 is 75mm, and the ratio of the length to the inner diameter is 4: 1; The stainless steel wire mesh in the product collector 4 is 200 mesh, and the power of the induced draft fan 5 is 250W. The cooling water flows of the upper and lower sections of the high-frequency plasma reactor 2 and cooler 3 are 20l / h, 50l / h and 100l / h respectively; argon is used as the plasma working gas, and the volume flow rates of the gas and cooling gas are 4l / h respectively. min and 12l / min; the flow rate of oxygen in inlet a and inlet c is 1.5l / min and 8l / min respectively; the operating pressure of the regulating system is the vacuum degree of 8mm water column; the setting of tungsten chloride raw material vaporizer The temp...

Embodiment approach 2

[0030] Tungsten chloride is used as the basic raw material. The power of the high-frequency plasma generator 1 is 3KW; the inner diameter of the high-frequency plasma reactor 2 is 25mm, and the ratio of the length to the inner diameter is 3:1; the inner diameter of the cooler 3 is 75mm, and the ratio of the length to the inner diameter is 4:1 ; The stainless steel wire mesh in the product collector 4 is 160 orders, and the power of the induced draft fan 5 is 300W. The cooling water flows of the upper and lower sections of the high-frequency plasma reactor 2 and cooler 3 are 25l / h, 75l / h and 200l / h respectively; with argon as the plasma working gas, the volume flow rates of gas and cooling gas are 5l / h respectively min and 15l / min; the flow rate of oxygen in inlet a and inlet c is 2l / min and 12l / min respectively, and the operating pressure of the regulating system is the vacuum degree of 15mm water column; the set temperature of the tungsten chloride raw material vaporizer is ...

Embodiment approach 3

[0032] Tungsten bromide is used as the basic raw material. The power of the high-frequency plasma generator 1 is 10KW; the inner diameter of the high-frequency plasma reactor 2 is 40mm, and the ratio of the length to the inner diameter is 4:1; the inner diameter of the cooler 3 is 150mm, and the ratio of the length to the inner diameter is 6:1 ; The stainless steel wire mesh in the product collector 4 is 120 orders, and the power of the induced draft fan 5 is 1200W. The cooling water flows of the upper and lower sections of the high-frequency plasma reactor 2 and cooler 3 are 100l / h, 250l / h and 500l / h respectively; with argon as the plasma working gas, the volume flow rates of gas and cooling gas are 20l / h respectively min and 100l / min; the flow rate of oxygen at inlet a and inlet c is 5l / min and 25l / min respectively; the operating pressure of the regulating system is the vacuum degree of 30mm water column; the set temperature of the tungsten bromide raw material vaporizer Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com