Automatic filter cloth scraping filter

A technology of filter cloth and filter machine, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc. It can solve the problems of easy blockage of filter cloth, waste of filter cloth, and easy overflow of liquid, so as to achieve the goal of not being wasteful. Cloth, high degree of automation, large filtration flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

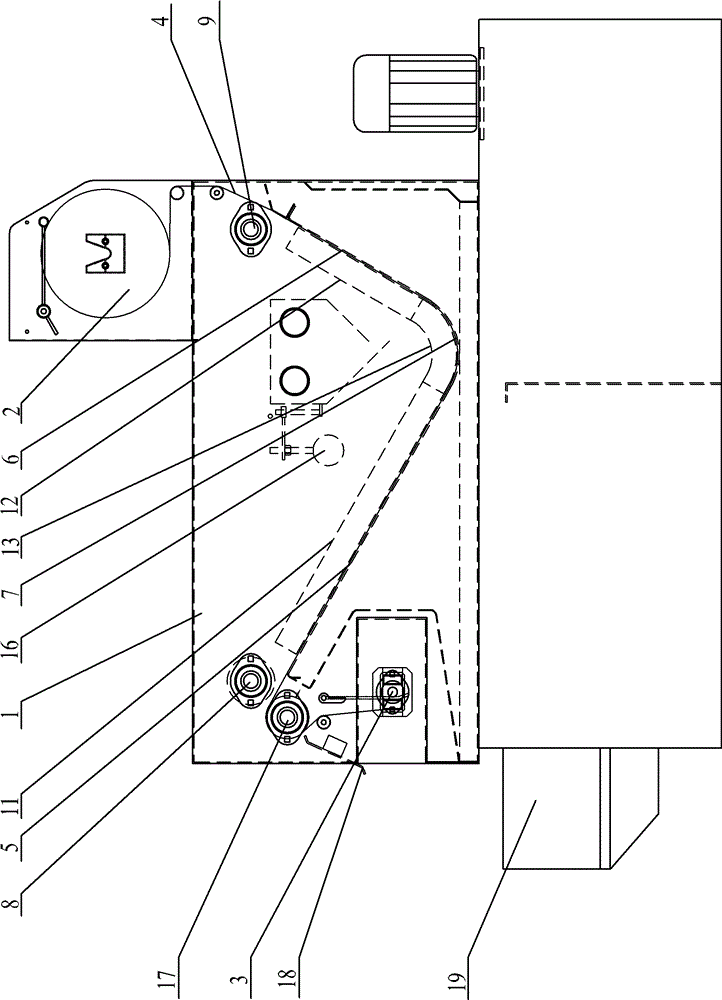

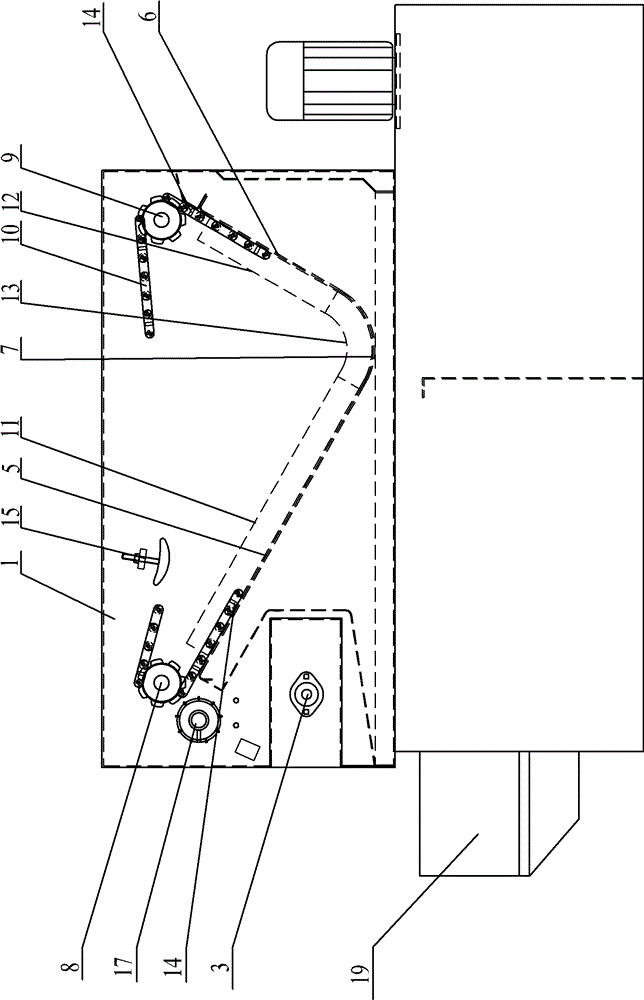

[0017] As shown in the figure: the filter cloth automatic scraping filter machine includes a feeding mechanism 2 and a winding mechanism 3 installed on the casing 1, and a filter cloth 4 is wound on the feeding mechanism 2 and the winding mechanism 3; The first screen 5, the second screen 6 and the curved connecting screen 7 are fixedly installed on the casing 1. The first screen 5 forms an acute angle with the horizontal plane, and the second screen 6 forms an acute angle with the horizontal plane. One end of the arc connecting net plate 7 is connected with the bottom end of the first net plate 5, and the other end of the arc connecting net plate 7 is connected with the bottom end of the second net plate 6, so that the first net plate 5, the second net plate 6. Connect with the arc-shaped connecting screen 7 to form a V-shaped filter cloth support leakage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com