Plate type and two surface filtration type micro-porous ceramic structure

A microporous ceramic and two-sided technology, applied in filtration separation, chemical instruments and methods, separation methods, etc., can solve the problems of reduced reliability, large equipment volume, easy damage during installation and use, etc., to maintain filtration accuracy and effluent water quality constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

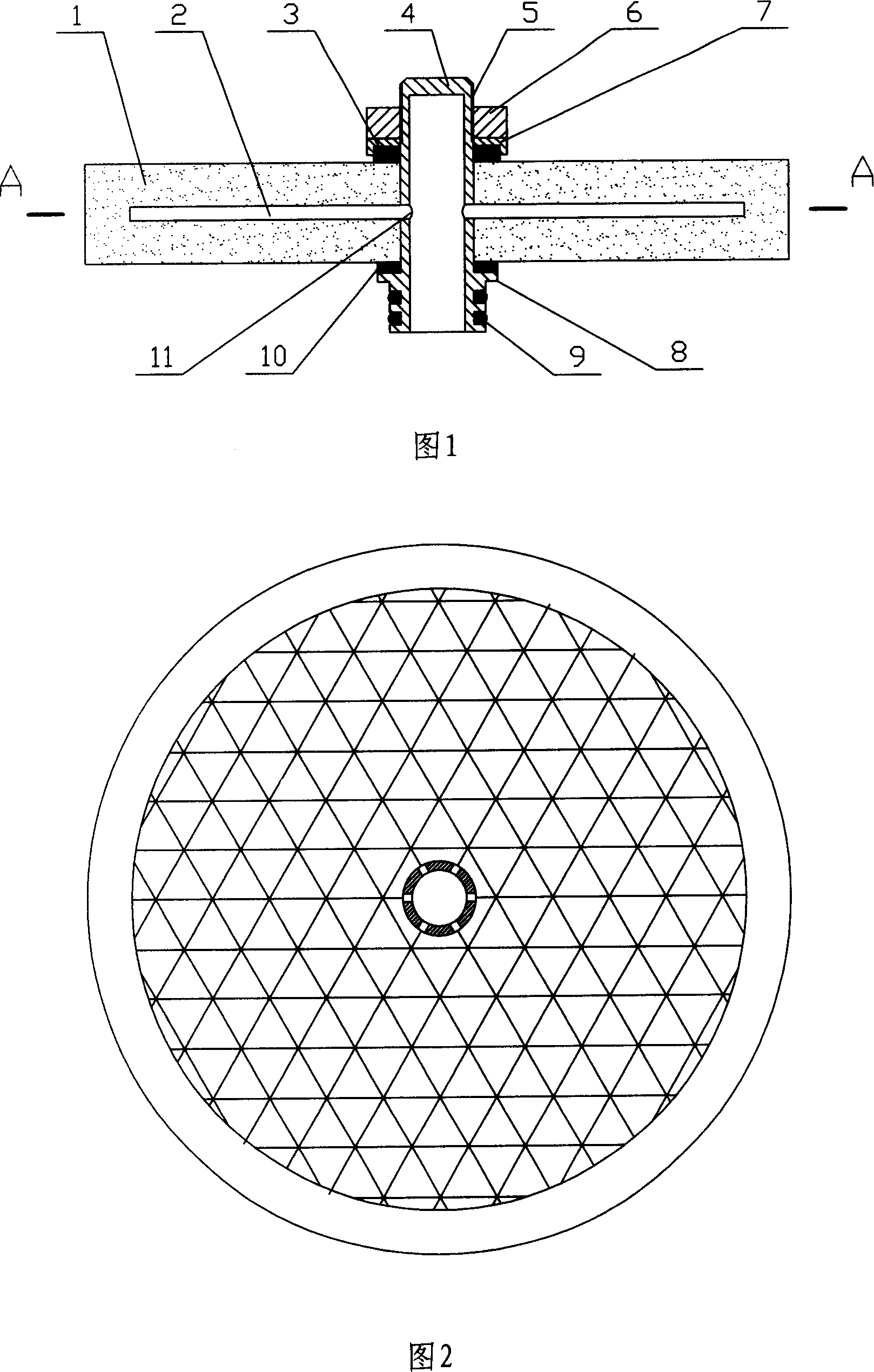

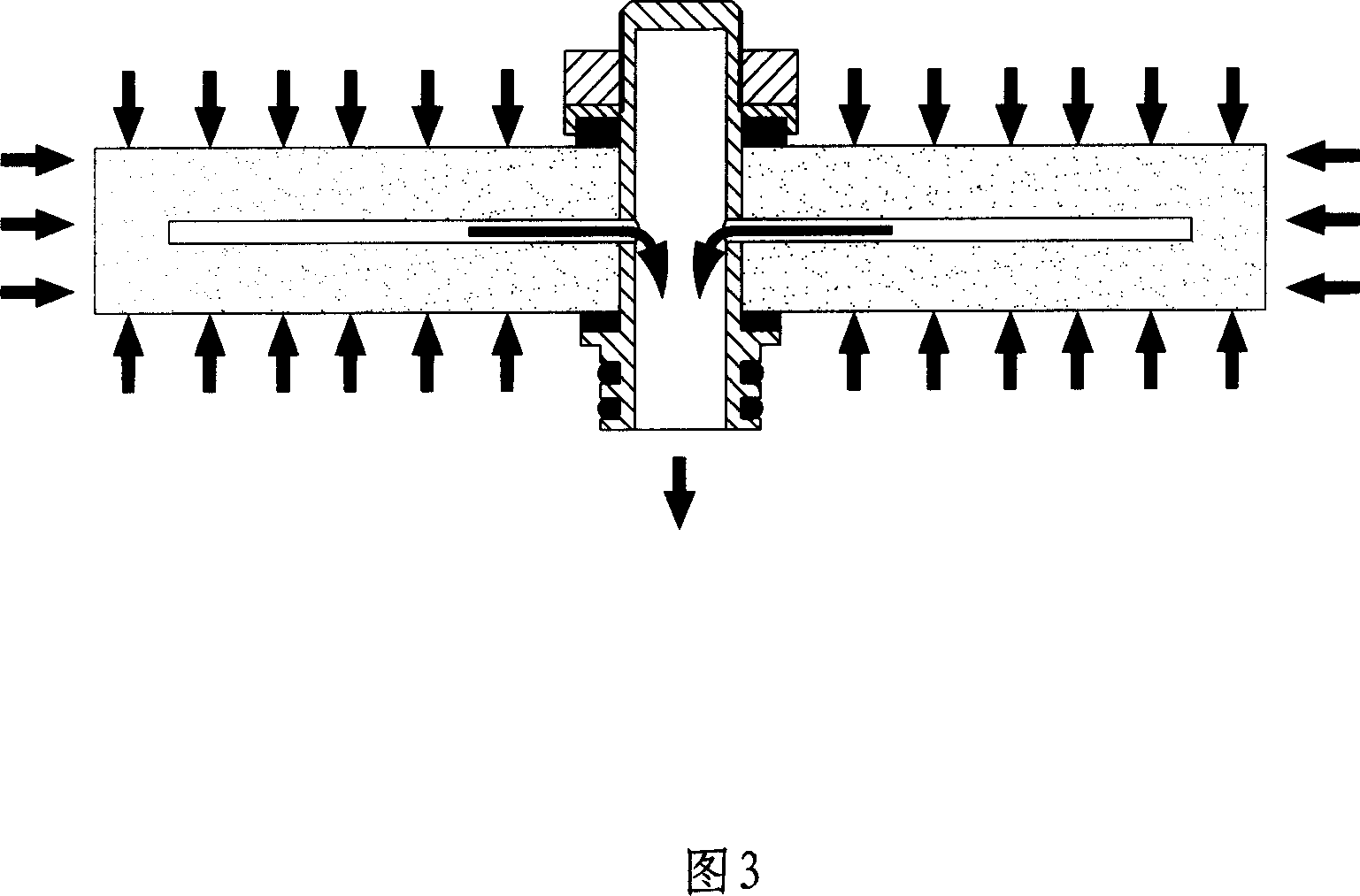

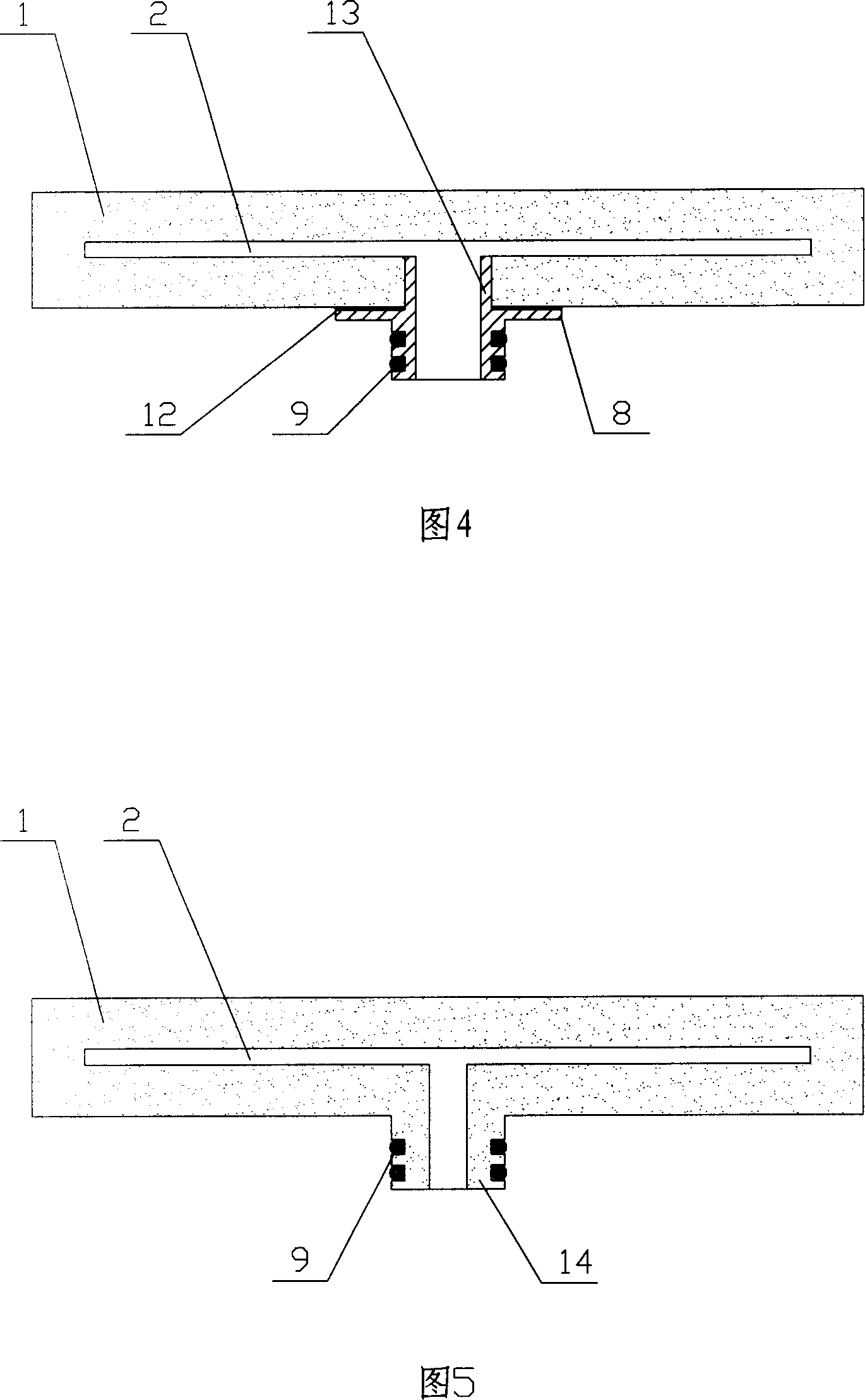

[0026] Embodiment 1: As shown in Fig. 1, Fig. 2 and Fig. 3, the plate-shaped double-sided filter microporous ceramic structure (1) of the present invention is connected to each other in the middle of the thickness direction and has a certain distance from the upper surface, the lower surface and the periphery. The mesh guide channel (2) has a through hole in which a guide core tube (4) can be assembled. The triangular mesh figure in Fig. 2 is a schematic diagram of the mesh channel. The mesh line in the figure is a water flow channel with a certain space, and the mesh is a microporous ceramic. The shape of the mesh can be triangular, polygonal, circular or any shape, but must be connected to each other. The upper end of the guide core tube (4) is closed, the lower end is open, the upper part has a thread (5), and the lower part is provided with a shoulder (8) that can compress the gasket (10) and an O-ring (9) that can be assembled ), the middle pipe wall is provided with a s...

Embodiment 2

[0027] Embodiment 2: As shown in FIG. 4 , the plate-shaped double-sided filter microporous ceramic structure (1) of the present invention is provided with interconnected mesh-shaped flow guide channels (2) in the middle of the thickness direction, and the middle part is provided with an assembleable flow guide The blind hole of the core tube (13); the upper port of the guide core tube (13) communicates with the mesh guide channel (2), and the lower part is provided with a shoulder (8) and an O-shaped seal that can be assembled In the groove of the ring (9), there is a sealing adhesive layer (12) between the upper surface of the shoulder (8) and the plate-shaped double-sided filter microporous ceramic structure (1), which can firmly connect the two into one. The requirements of the mesh guide channel (2) are the same as those of the first embodiment.

Embodiment 3

[0028] Embodiment three: in conjunction with shown in Fig. 5, the present embodiment is to also adopt the same material as the described two-sided filter microporous ceramic structure (1) to make the guide core tube (14) It is integrated with the plate-shaped homogeneous microporous ceramic (1), and the core tube (14) is provided with a groove that can be assembled with an O-ring (9). (14) The setting position is all identical with embodiment two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com