Vacuum drum filtering system

A filtration system and vacuum drum technology, applied in filtration and separation, moving filter element filters, separation methods, etc., can solve the problems of short service life, high-density accumulation of sediments, low work efficiency, etc., to improve the scope of application, High filtration efficiency, easy disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

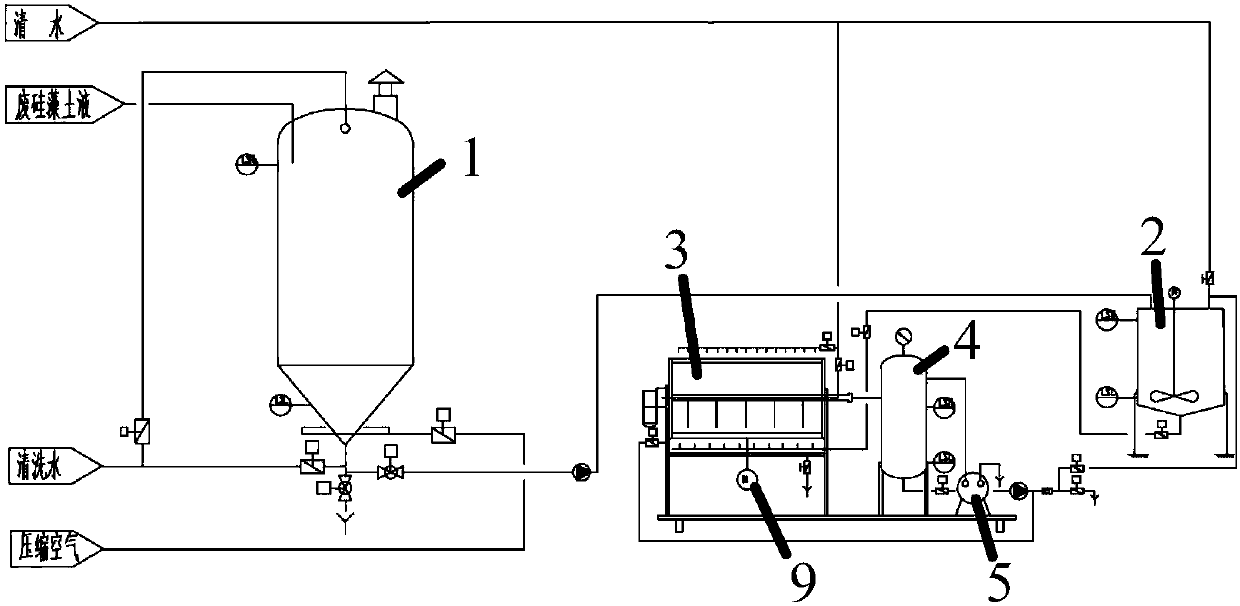

[0030] A vacuum drum filtration system is described as figure 1 As shown, it includes a waste diatomite storage tank 1, a mixing tank 2, a vacuum drum filter 3, a raw material temporary storage cylinder 4 and a vacuum pump 5 connected in sequence, and it is characterized in that the vacuum drum filter 3 includes:

[0031] The bracket 6 is arranged in the filter tank 7;

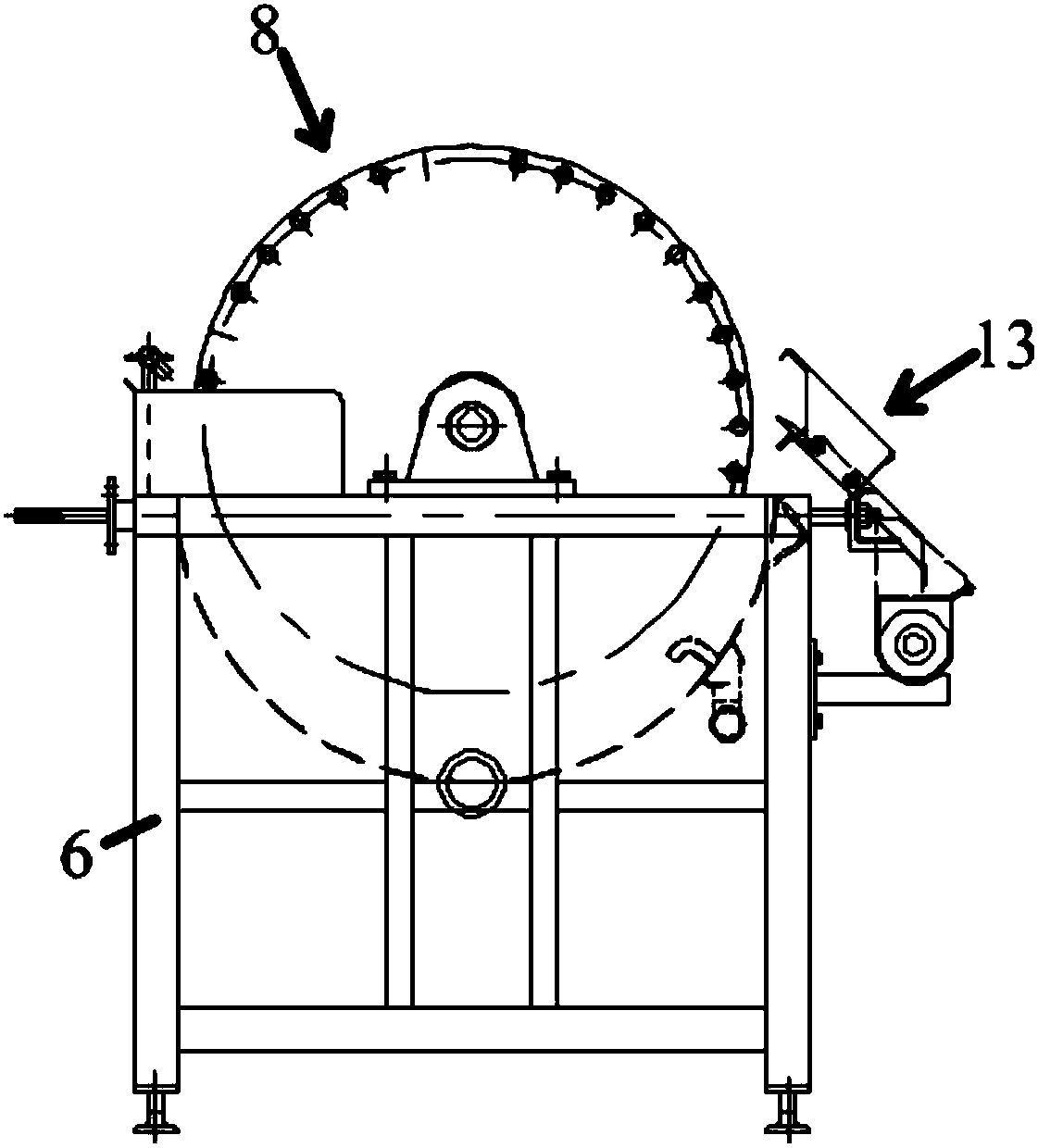

[0032] The drum 8 is connected with the power mechanism 9 through transmission, and is rotatably installed on the support 6. The drum 8 is respectively provided with a sewage discharge pipe 10 connected with the filter tank 7 and a discharge pipe 10 connected with the raw material temporary storage cylinder 4. Material tube;

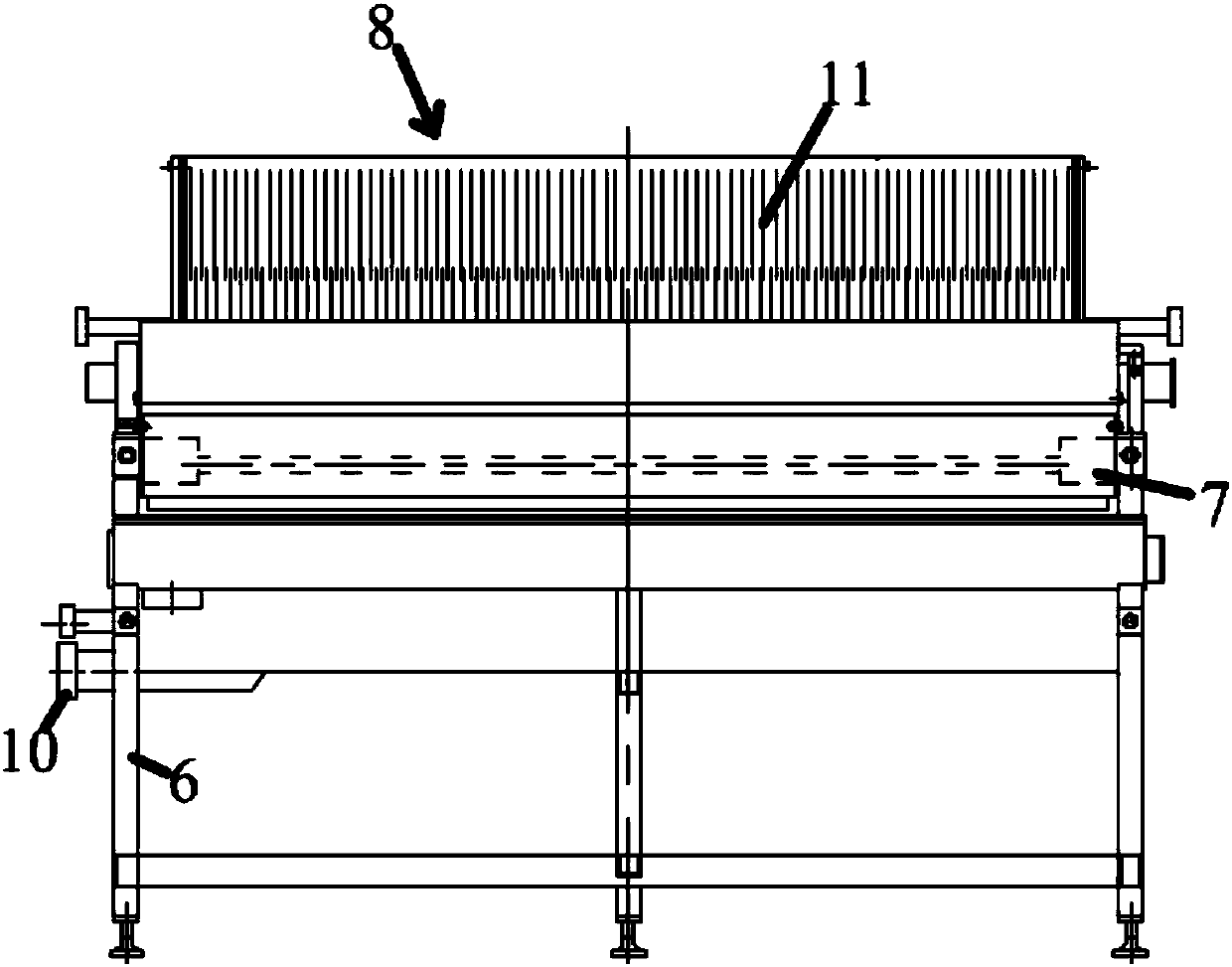

[0033] Such as figure 2 , image 3 and Figure 4 As shown, the filter screen 11 is arranged in the drum 8, and the filter screen 11 includes a number of wedge-shaped metal wires and a number of fixing ribs, and the fixing ribs are arranged in a circular array to form a columnar fixi...

Embodiment 2

[0041] A vacuum drum filtration system is described as figure 1 As shown, it includes a waste diatomite storage tank 1, a mixing tank 2, a vacuum drum filter 3, a raw material temporary storage cylinder 4 and a vacuum pump 5 connected in sequence, and it is characterized in that the vacuum drum filter 3 includes:

[0042] The bracket 6 is arranged in the filter tank 7;

[0043] The drum 8 is connected with the power mechanism 9 through transmission, and is installed on the support 6 for rotation. The drum 8 is respectively provided with a sewage discharge pipe 10 connected with the filter tank 7 and a discharge pipe 10 connected with the temporary storage cylinder 4 for raw materials. Material tube;

[0044] Such as figure 2 , image 3 and Figure 4 As shown, the filter screen 11 is arranged in the drum 8, and the filter screen 11 includes a number of wedge-shaped metal wires and a number of fixing ribs, and the fixing ribs are arranged in a circular array to form a colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com