Assembled filter for micro-irragation

A combined filter technology, which is applied in the field of sandy water treatment in farmland micro-irrigation, can solve the problems of complex connection, large resistance, and high manufacturing cost of filtering equipment, and achieve low manufacturing and use costs, reduce water resistance, and increase filtration flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

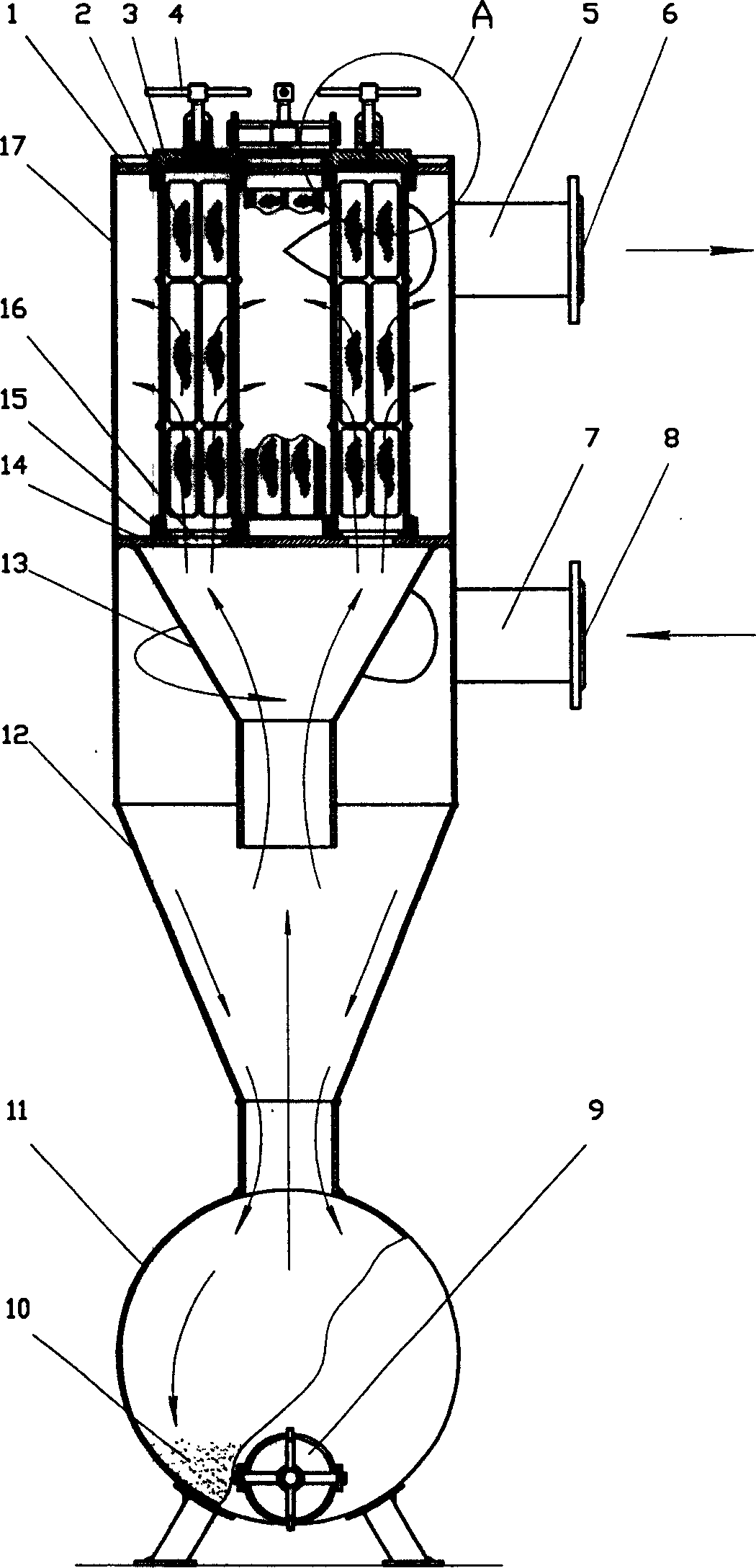

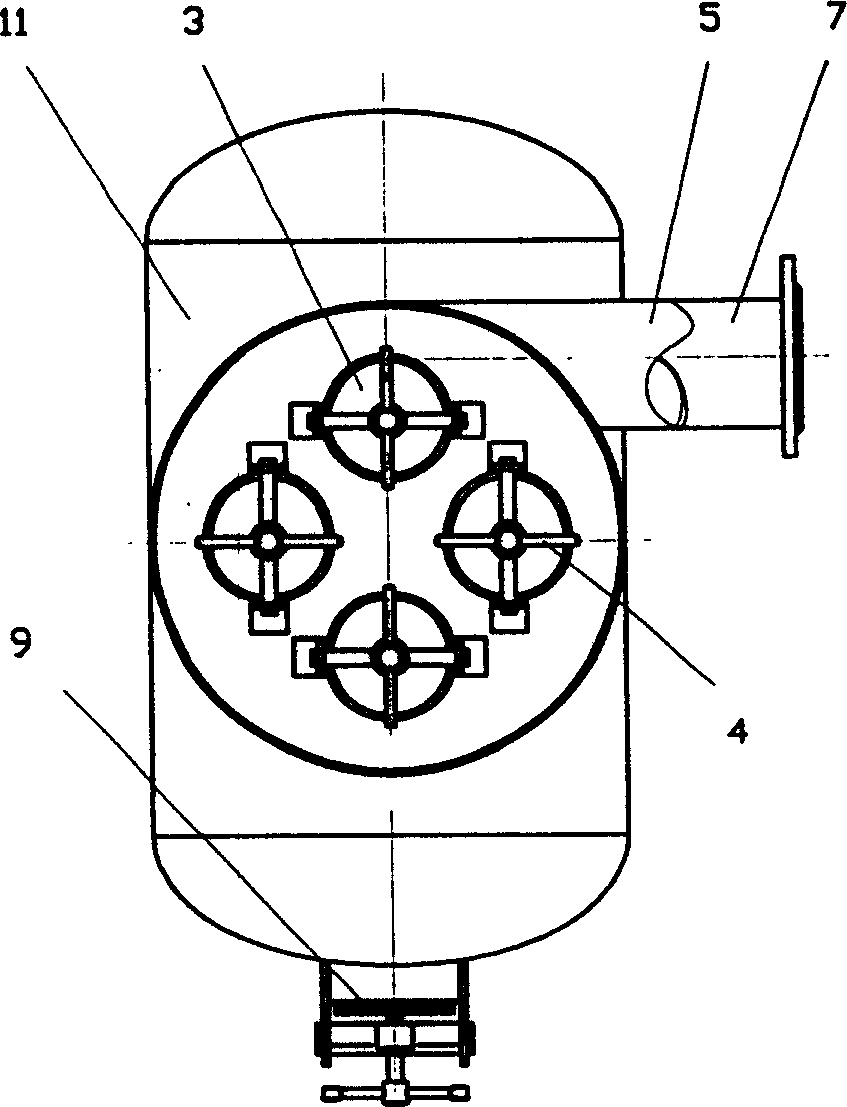

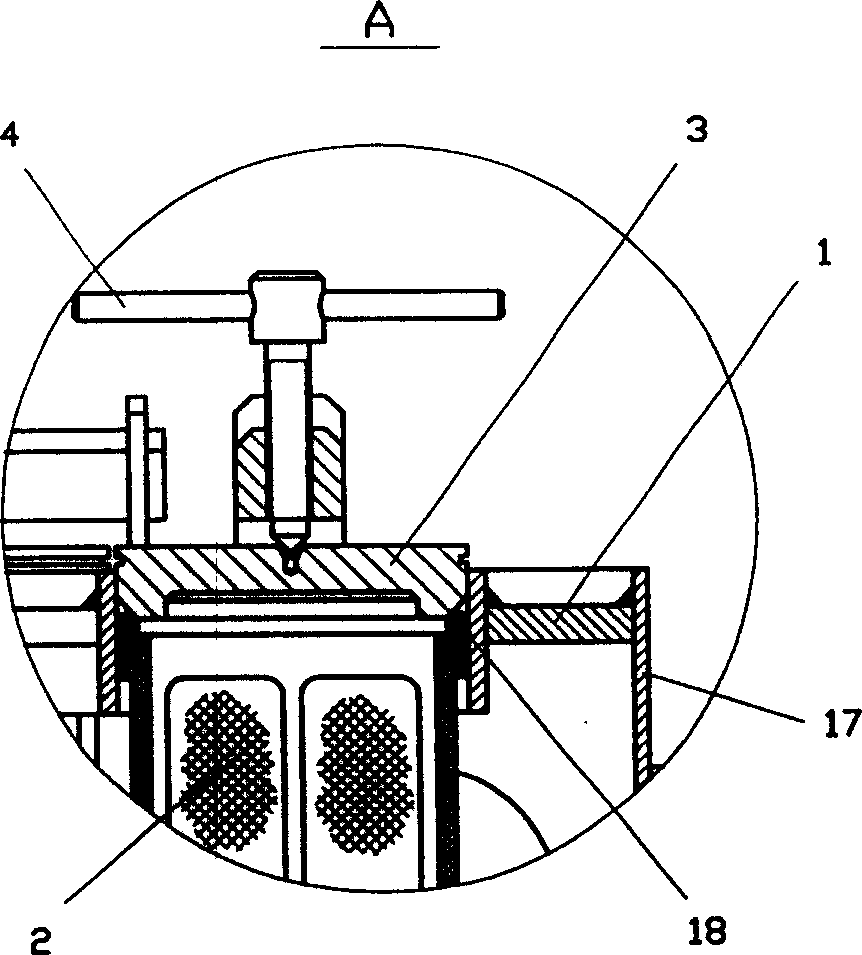

[0017] figure 1 The main innovation of the combined filter for micro-irrigation shown is that the centrifugal sand-water separation chamber 2, which is mainly used for sediment filters, is combined with multiple sets of basket-type filter elements 2, and the filter is a cone-shaped package structure as a whole. , the filter element is arranged in the upper cone 13, and the centrifugal sand-water separation chamber and the sand collection tank 9 are arranged at the bottom, and the irrigation water enters the sand-water separation chamber 12 from the water inlet at the bottom, and the silt is centrifugally deposited into the sand collection tank 11. The filtered water enters the combined filter element 2 through the upper cone 13 and flows out from the water outlet 6 . This design method not only reduces the occupied area of the filter, but also saves the manufacturing cost, so that the equipment cost is greatly reduced.

[0018] The filter element 2 of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com