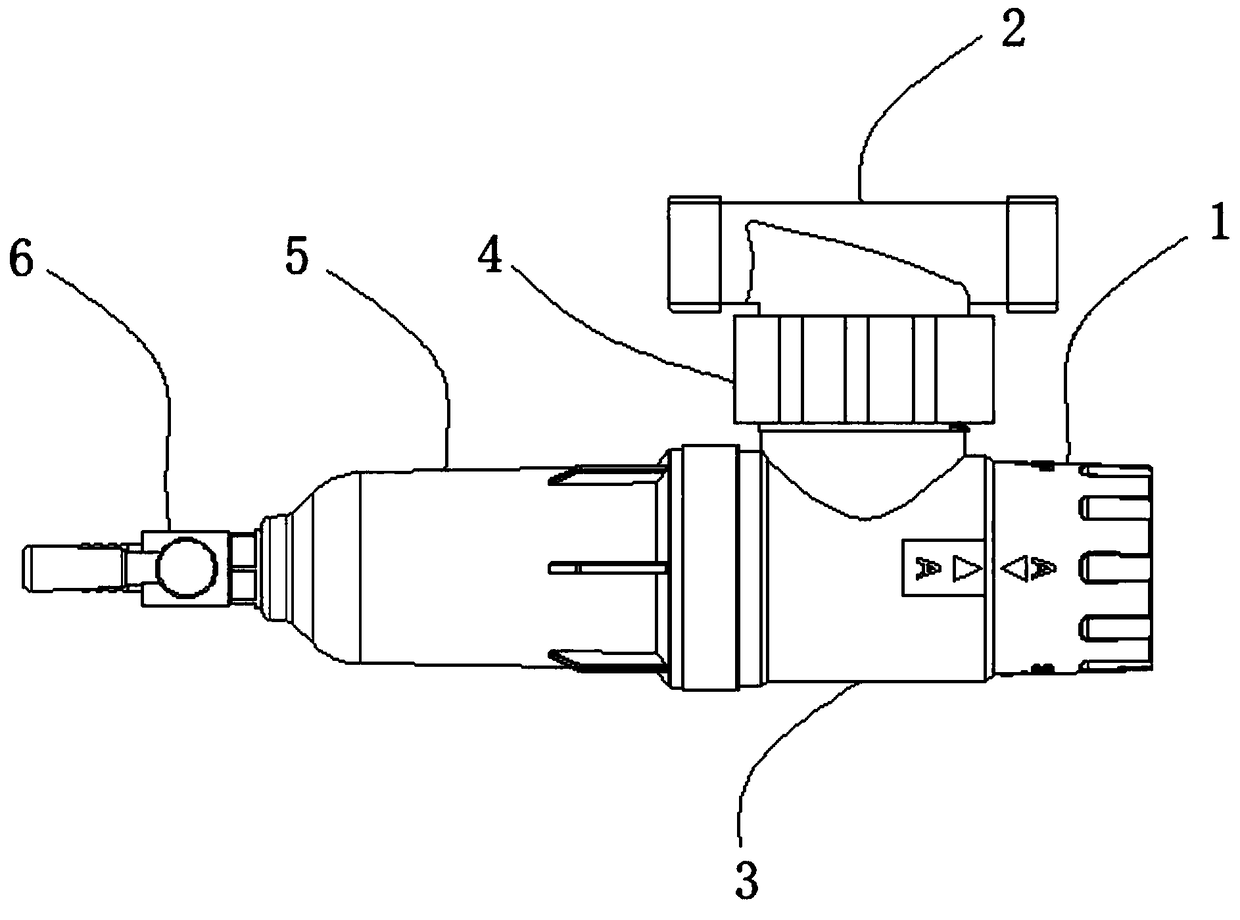

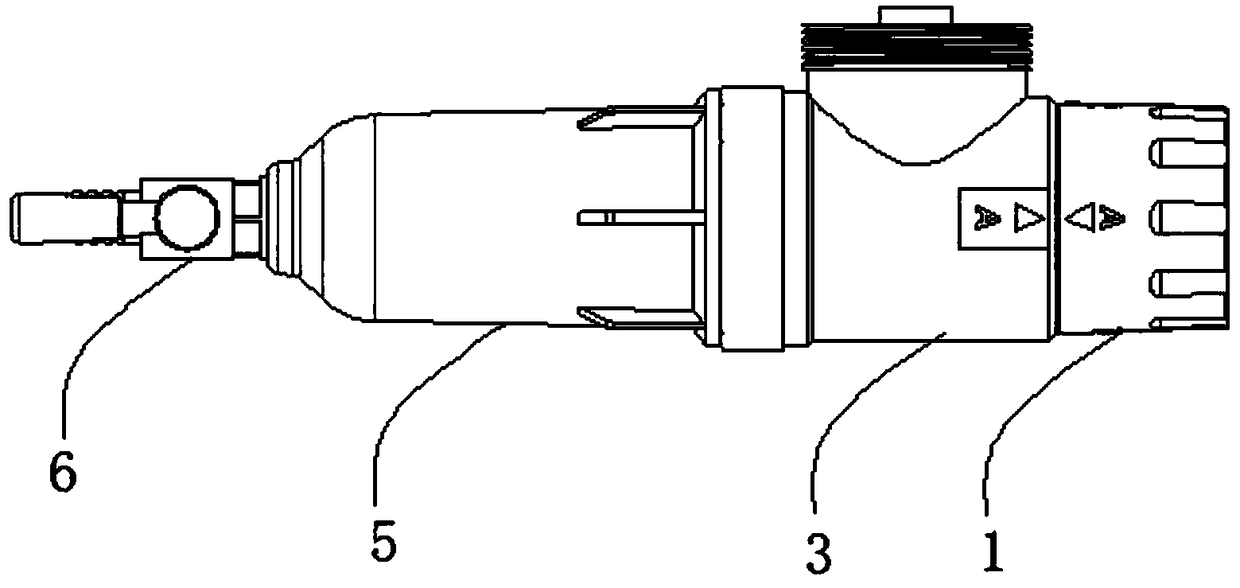

Universal multifunctional pre-filter

A pre-filter and multi-functional technology, applied in the direction of fixed filter elements, filtration separation, chemical instruments and methods, etc., can solve problems such as troublesome operation and affecting production operations, and achieve convenient application, simple operation and maintenance process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

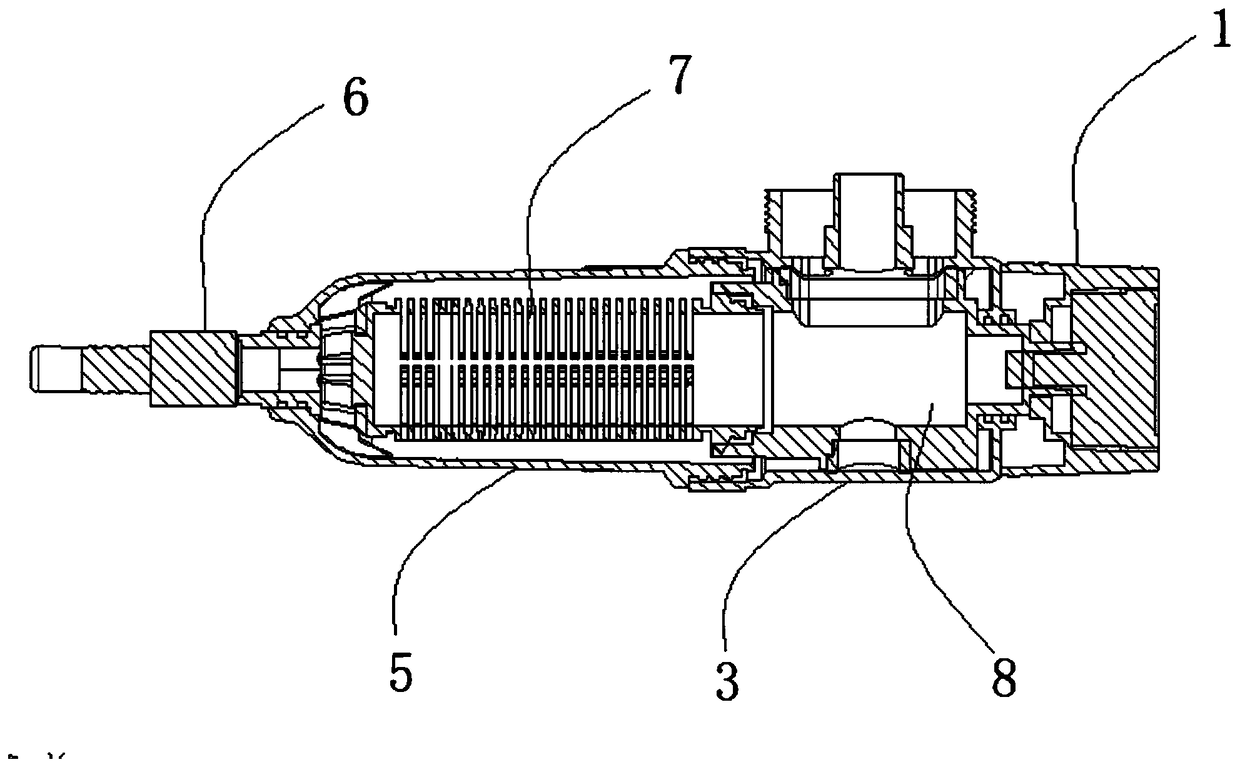

[0042] When filtering, close the drain valve 6 at the end of the filter housing 5, turn the adjusting handle 1 to adjust the water outlet port 809 of the adjusting valve 8 to a position communicating with the water outlet port 306 of the water inlet and outlet support 3. The raw water to be filtered is from The water inlet channel 203 of the dual-channel valve 2 enters through the water inlet 208 and enters the inner cavity composed of the water tank one 206 and the water tank 305, then flows through the raw water inlet 311 and enters the filter housing 5 through the water inlet channel 811 of the regulating valve 8. Under the action of water pressure, the raw water is intercepted and filtered by the filter screen 72 of the filter 7 and enters the inner cavity of the filter cartridge frame 71. The dirt is intercepted and embedded in the mesh of the filter screen 72. The purified water after filtration is Under the action of water pressure, it flows upwards into the water passage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com