Bulk flow and self-cleaning net type filter

A mesh filter, self-cleaning technology, applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of high manufacturing cost, low operating cost, large floor space, etc., and achieve low cost , high degree of automation and less water demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

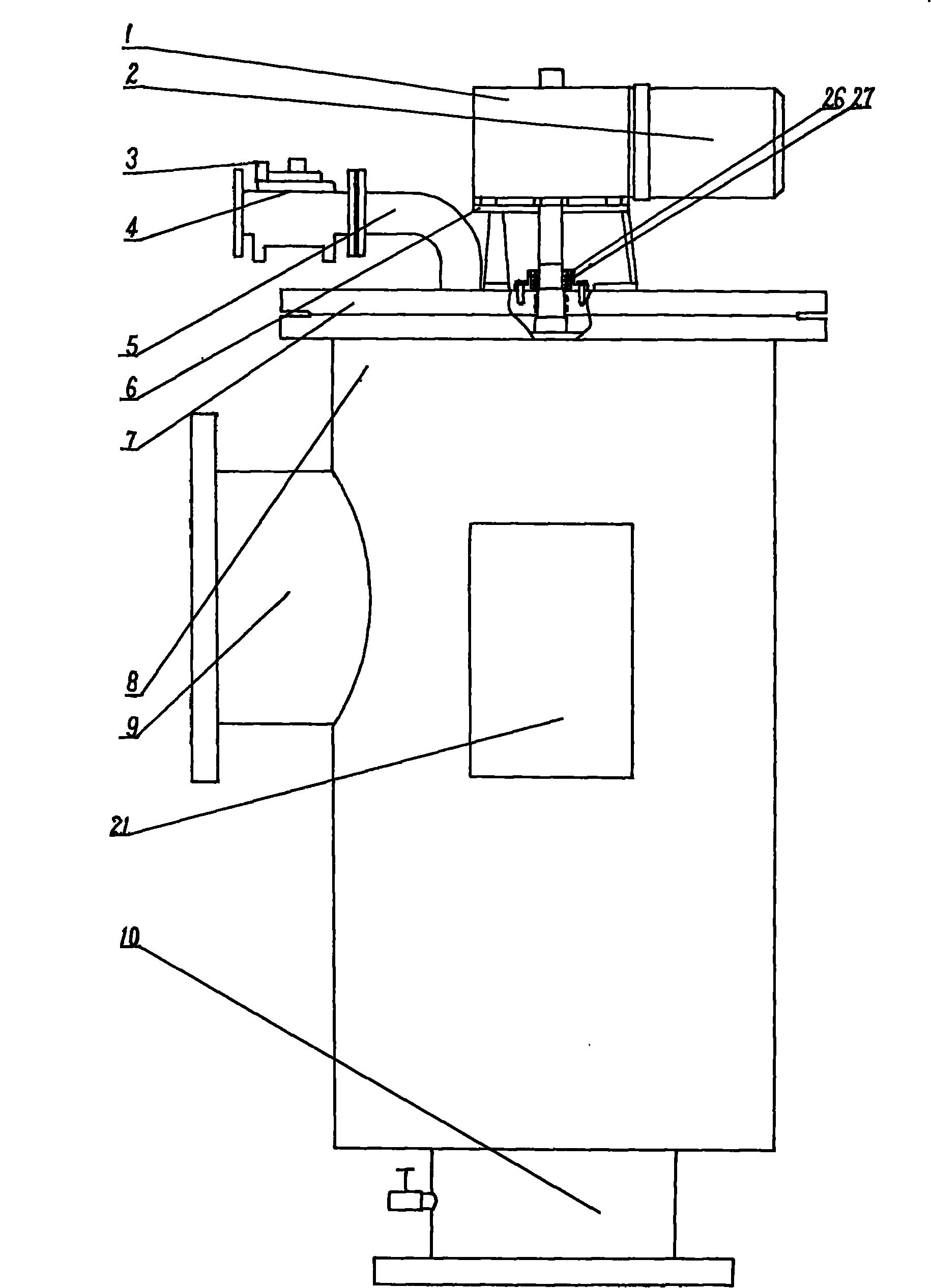

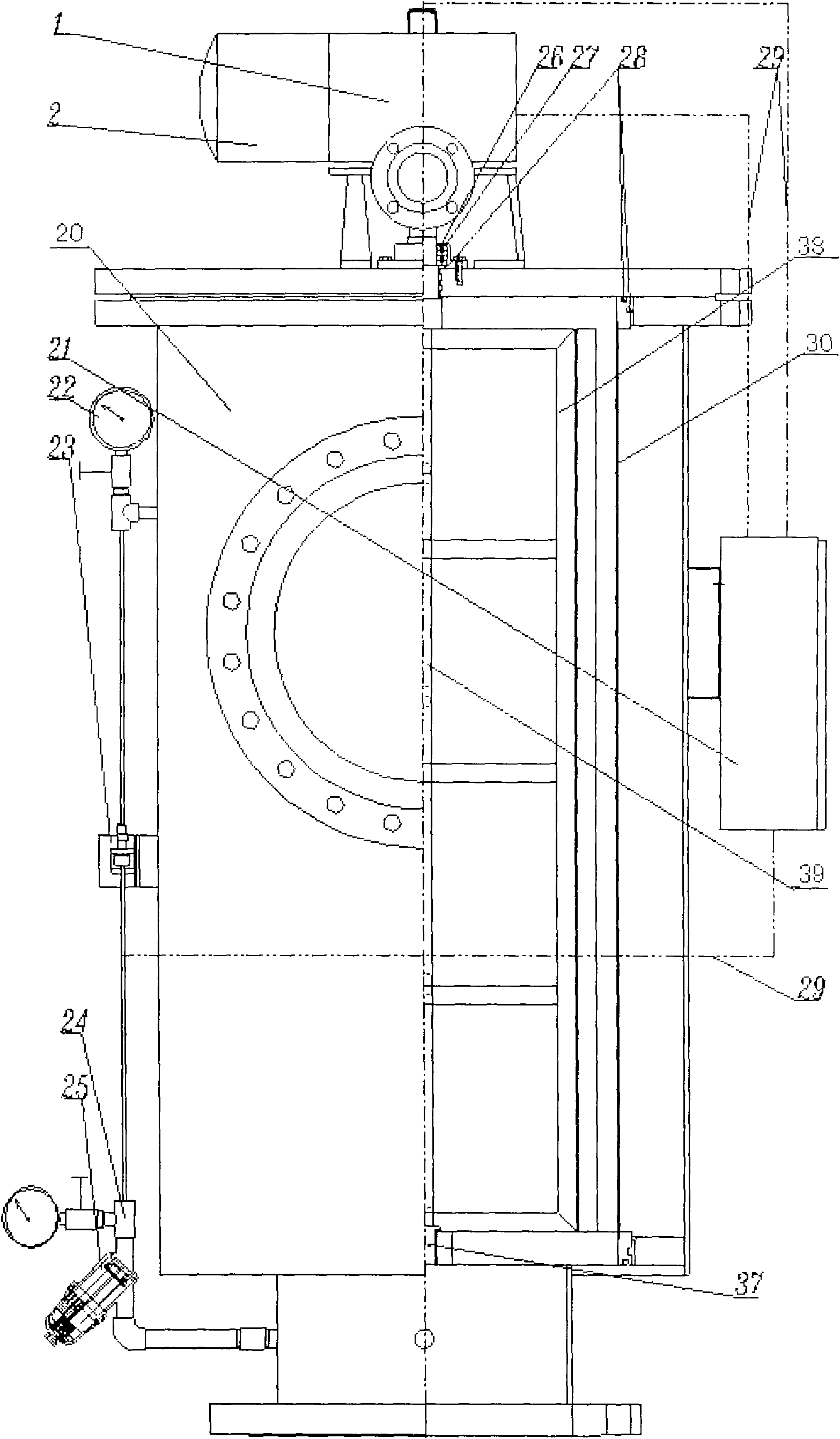

[0022] A kind of large-flow self-cleaning screen filter is made up of tank body 8, power system, control system and filter chamber 20 (see figure 1 , figure 2 ). Tank body 8 bottom is provided with water inlet 10, and its side is provided with water outlet 9, and its top is provided with and is respectively provided with blowdown outlet 5, power system, and its inside is provided with filter chamber 20, and this filter chamber 20 is respectively connected with power system, The control system and the water outlet 9 are connected.

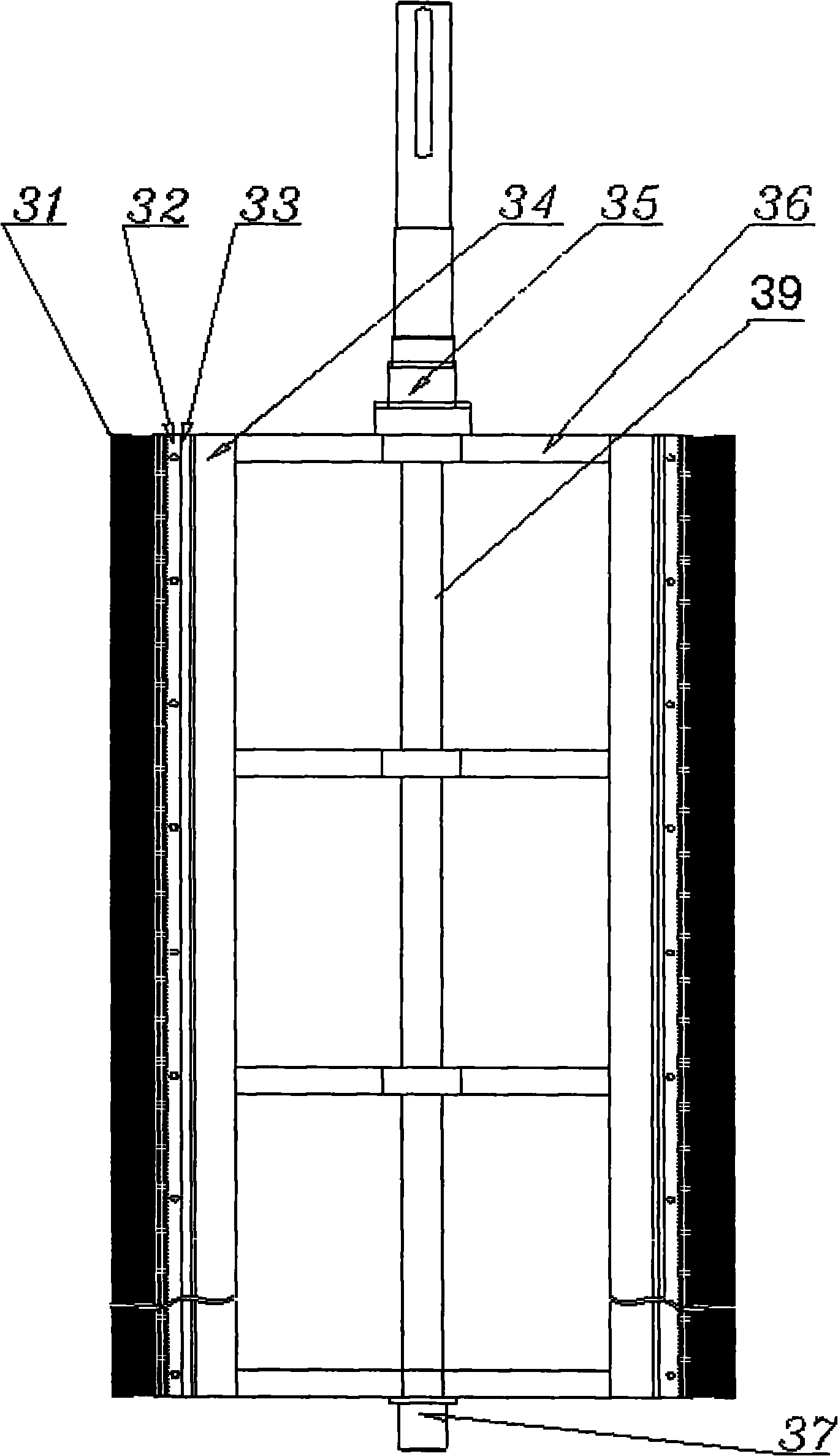

[0023] Wherein: the filter chamber 20 includes a wedge-shaped filter screen cylinder 30 and a rotating stainless steel wire brush assembly 38 built in the wedge-shaped filter screen cylinder 30 . The wedge-shaped filter screen cylinder 30 is connected with the water inlet 10; the rotating stainless steel wire brush assembly 38 includes an interconnected wire brush upper shaft 35, a wire brush middle shaft 39 and a wire brush lower shaft 37 locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com