Patents

Literature

32results about How to "Operation without downtime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for determining indicator diagram of electrical parameters of rod-pumped well

ActiveCN104533382AThe test is convenient and practicalSimple and convenient practical measurementSurveyConstructionsWellheadDecomposition

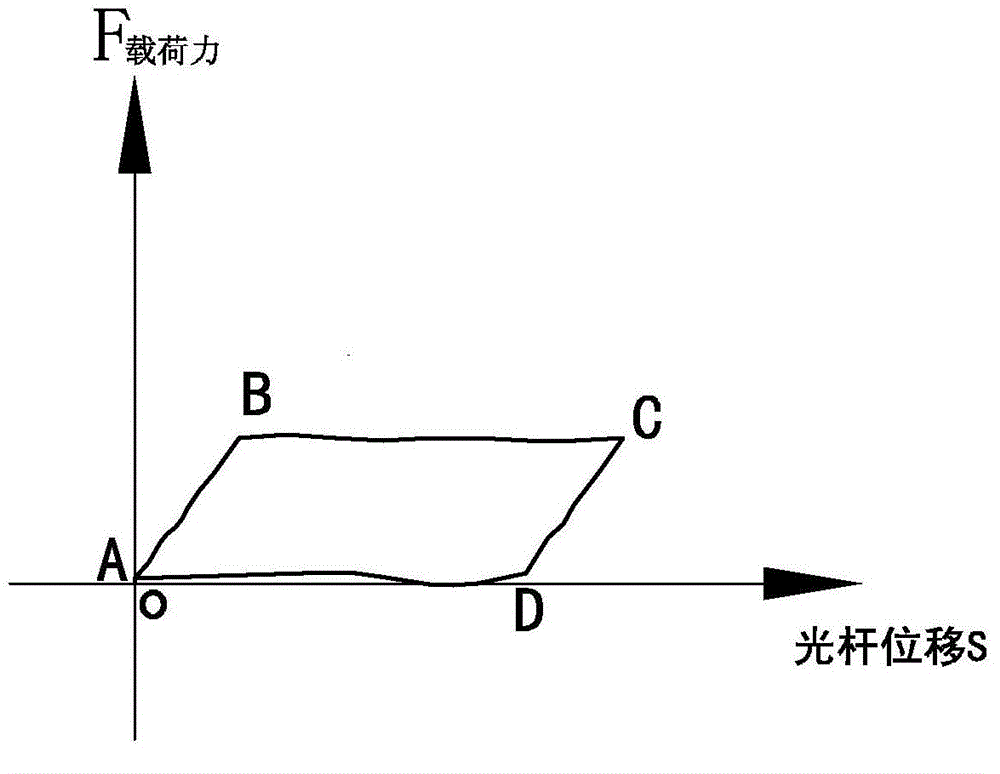

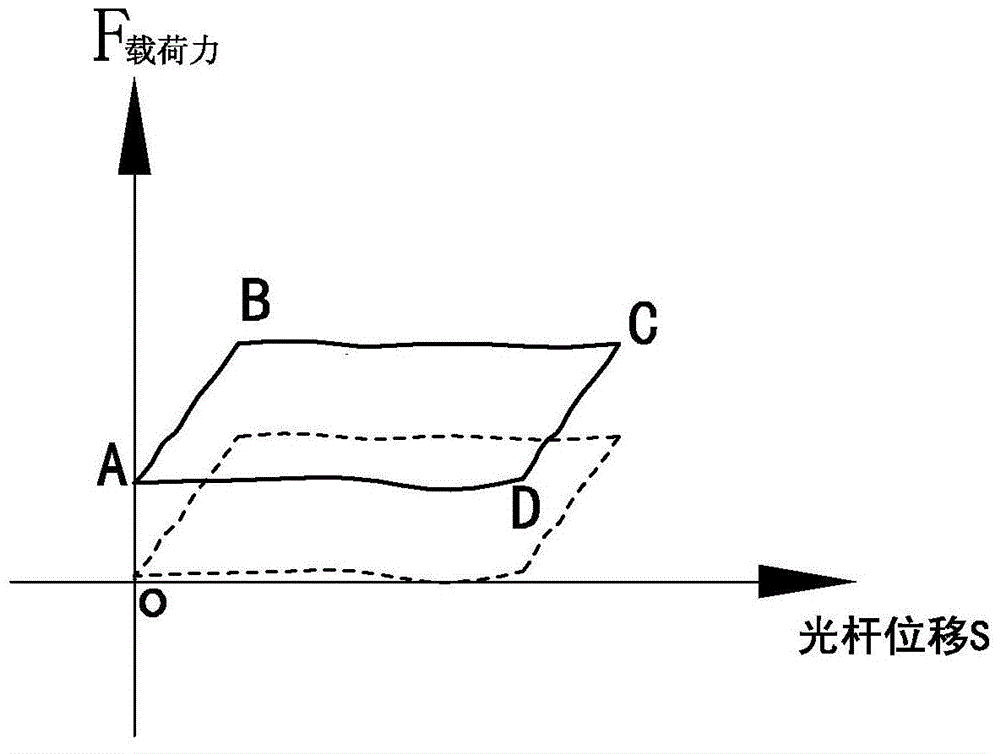

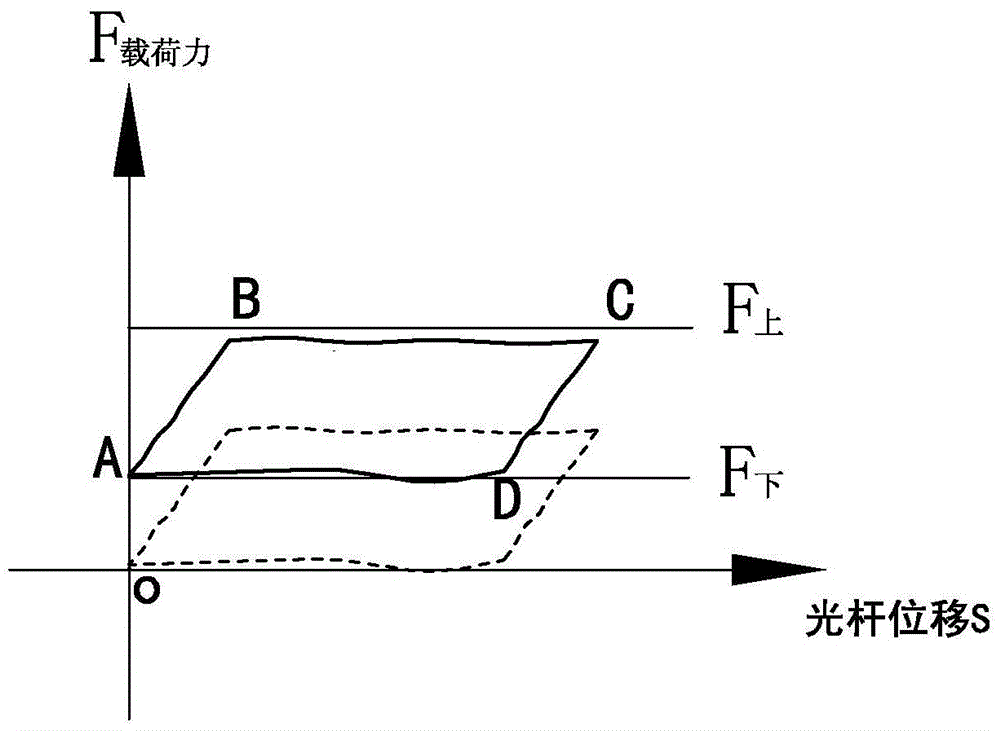

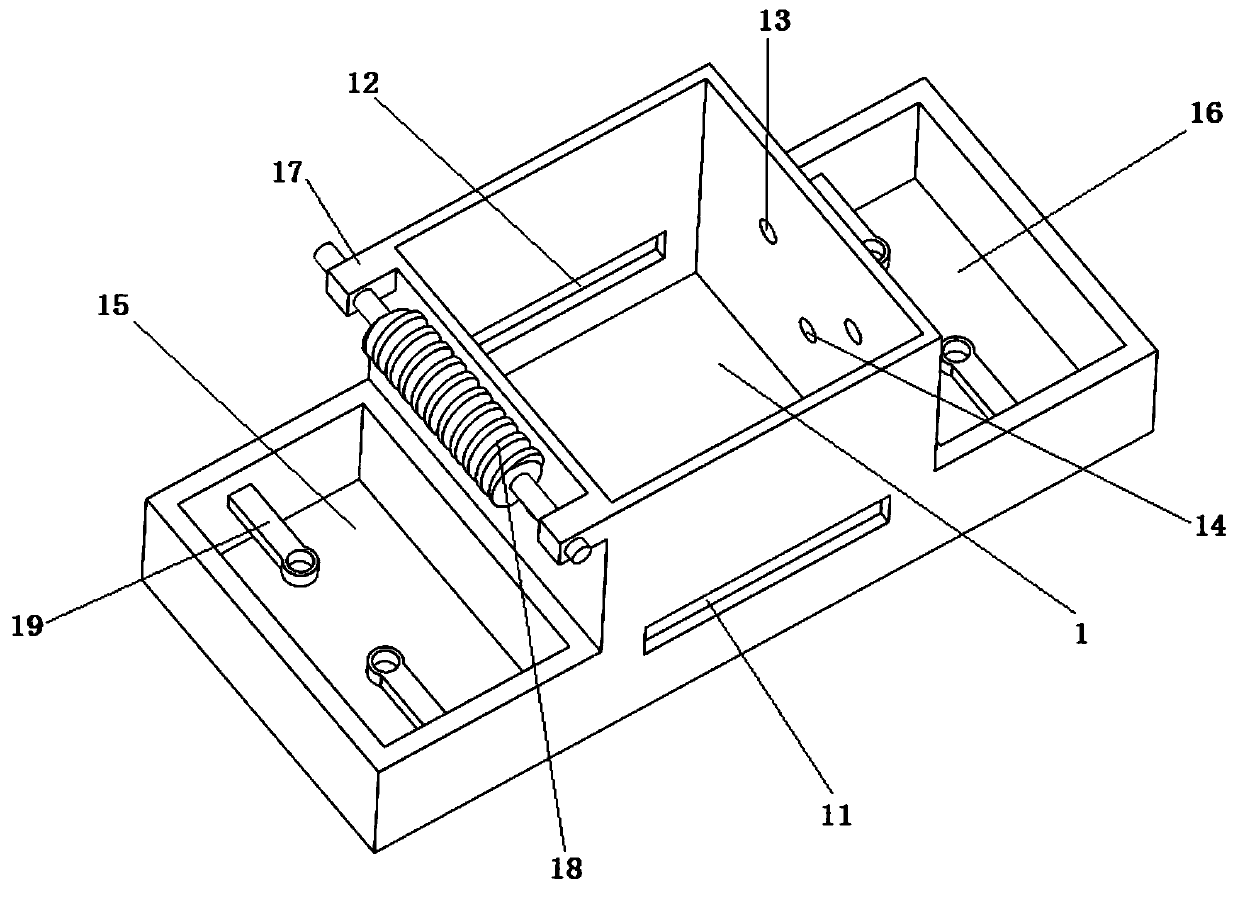

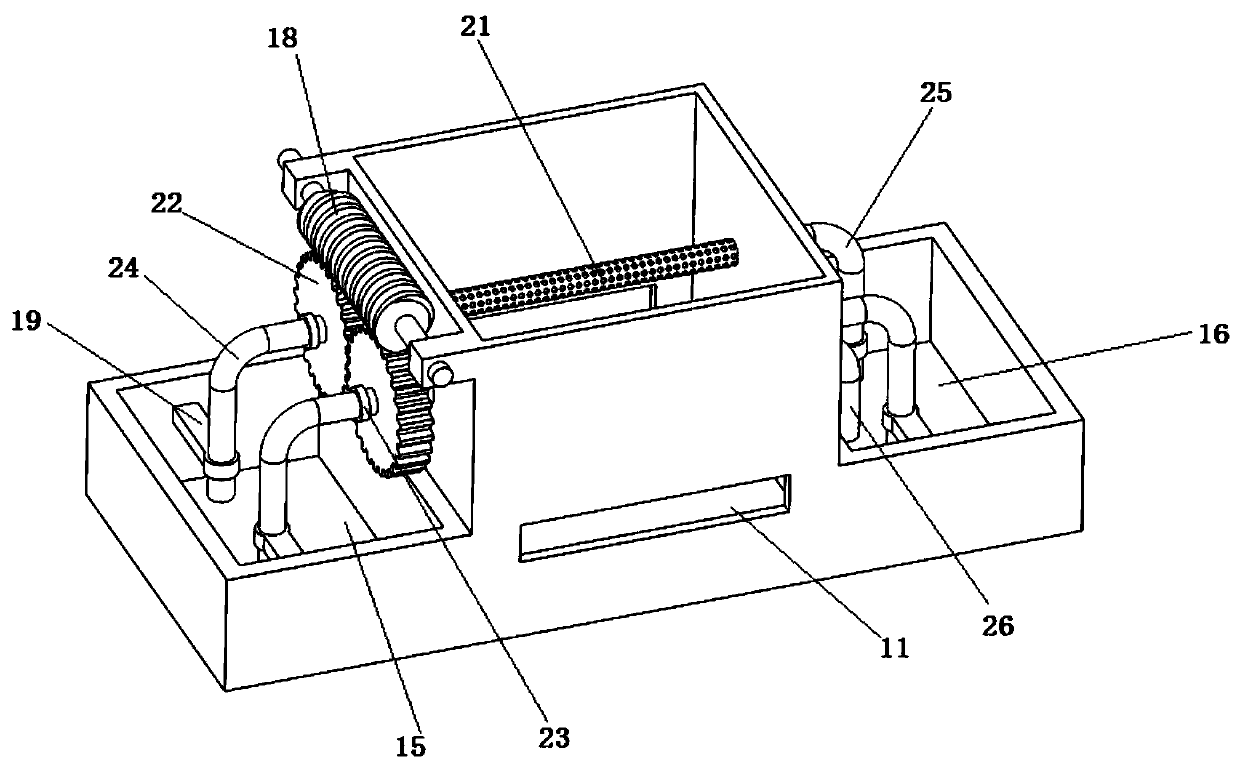

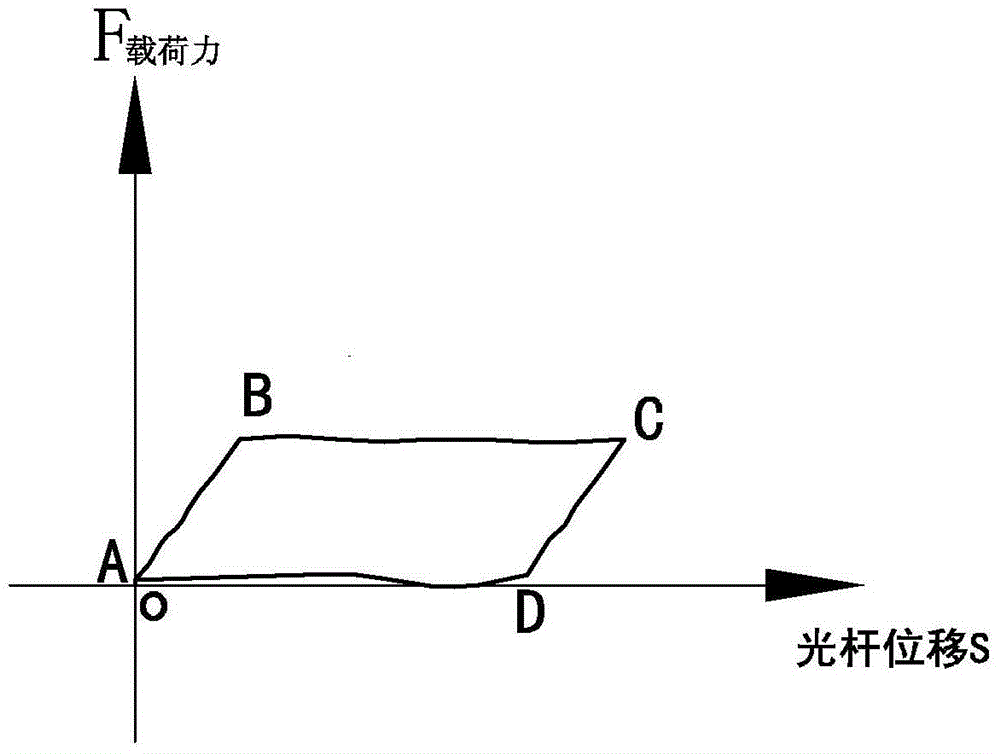

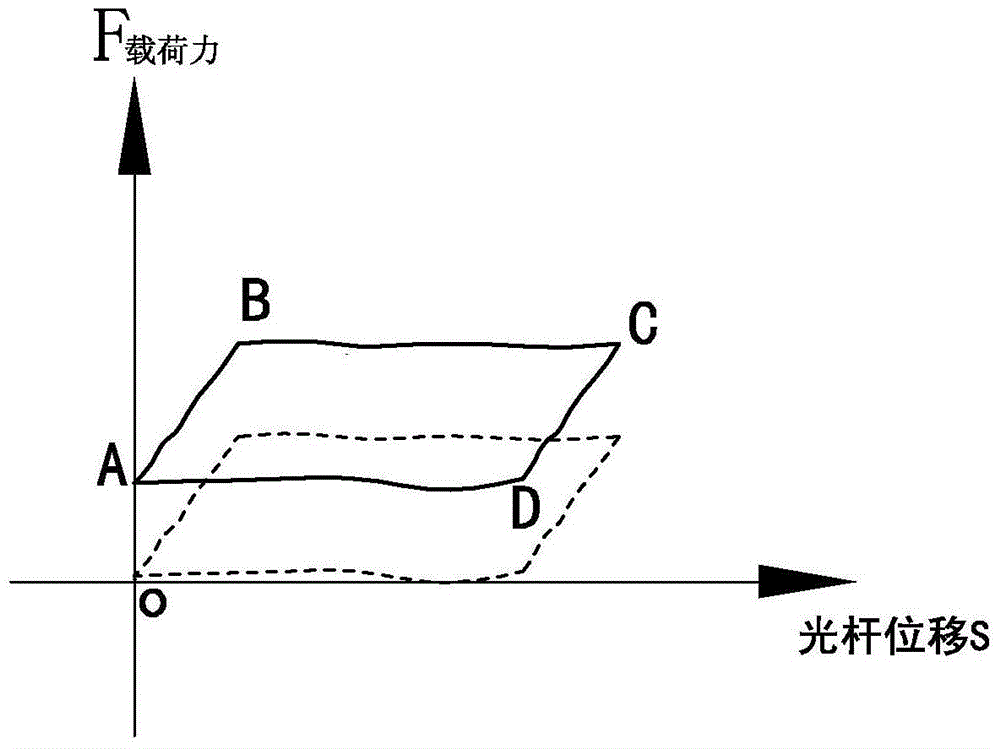

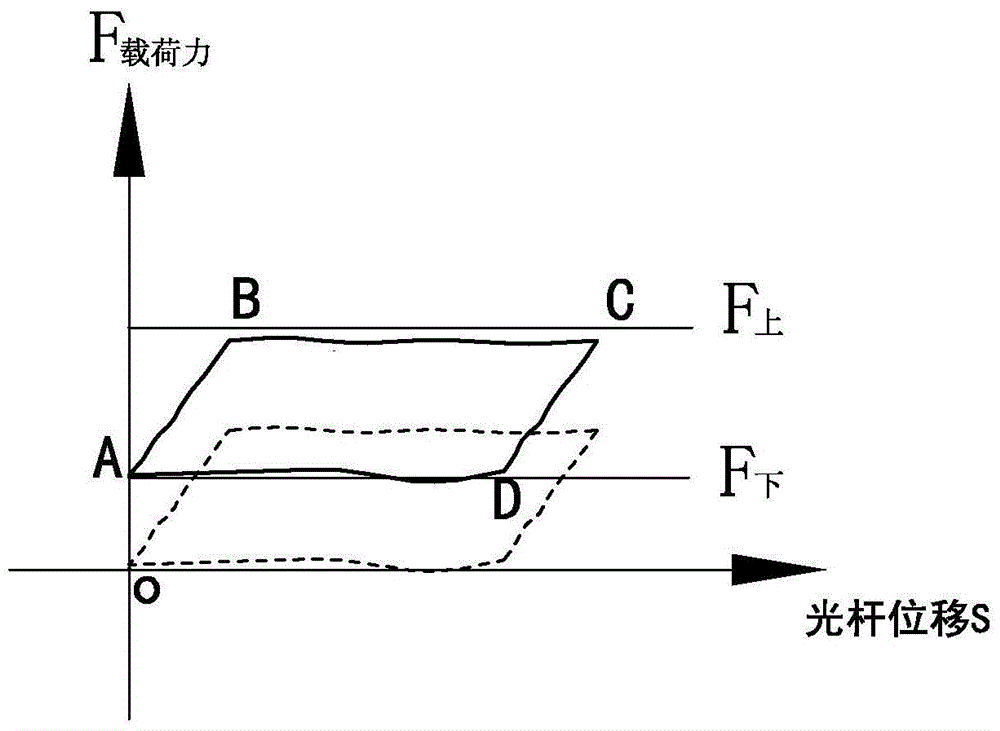

The invention provides a method for determining an indicator diagram of electrical parameters of a rod-pumped well and belongs to the technical field of oil production of oil fields. The method aims at achieving convenient and practical measurement of the indicator diagram of the electrical parameters of the rod-pumped well on site. The method is characterized in that top dead center moments and bottom dead center moments are determined periodically, active powers of electrical parameters of up strokes and down strokes of the rod-pumped well are processed in a decomposition mode, and input end active power of the up strokes and the down strokes is obtained respectively and are calculated and converted into wellhead loading force; adjustment is conducted through balance blocks for operation balance of a pumping unit, actually measured data are used for further correcting the weights of the crank balance blocks of the oil pumping unit or retrieving the weights of the crank balance blocks after adjustment, actually measured active power is converted into wellhead loading force F<upper force i>, wellhead loading force F<lower force i> and superposed wellhead loading force F<upper and lower force i>, the wellhead loading force F<upper force i>, the wellhead loading force F<lower force i> and the superposed wellhead loading force F<upper and lower force i> are calculated, superposed and converted into wellhead loading force, and the indicator diagram of trends of the electrical parameters is determined before and after superposition with the crank balance blocks. According to the method, on-site testing is convenient and practical, and online automatic measurement is achieved.

Owner:哈尔滨斯特凯峰电子有限公司

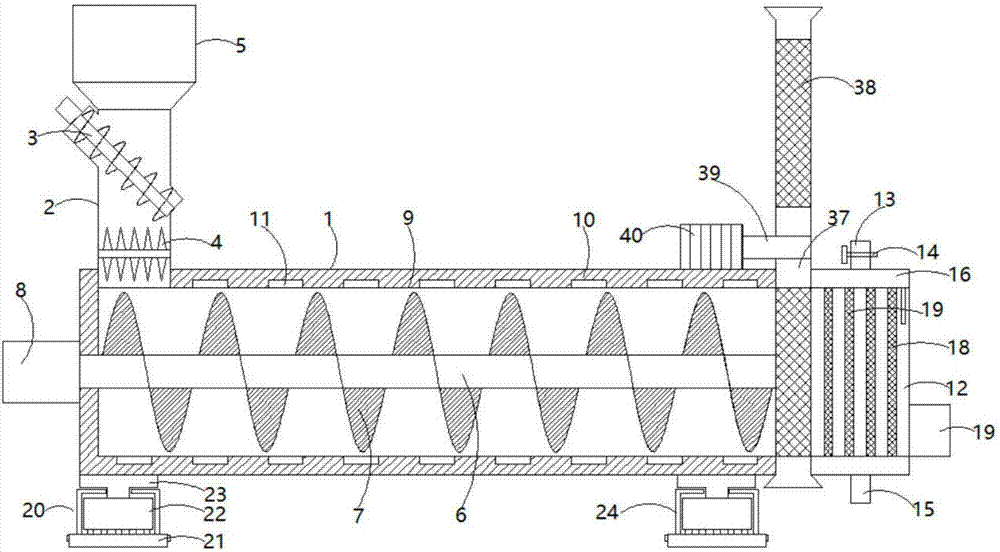

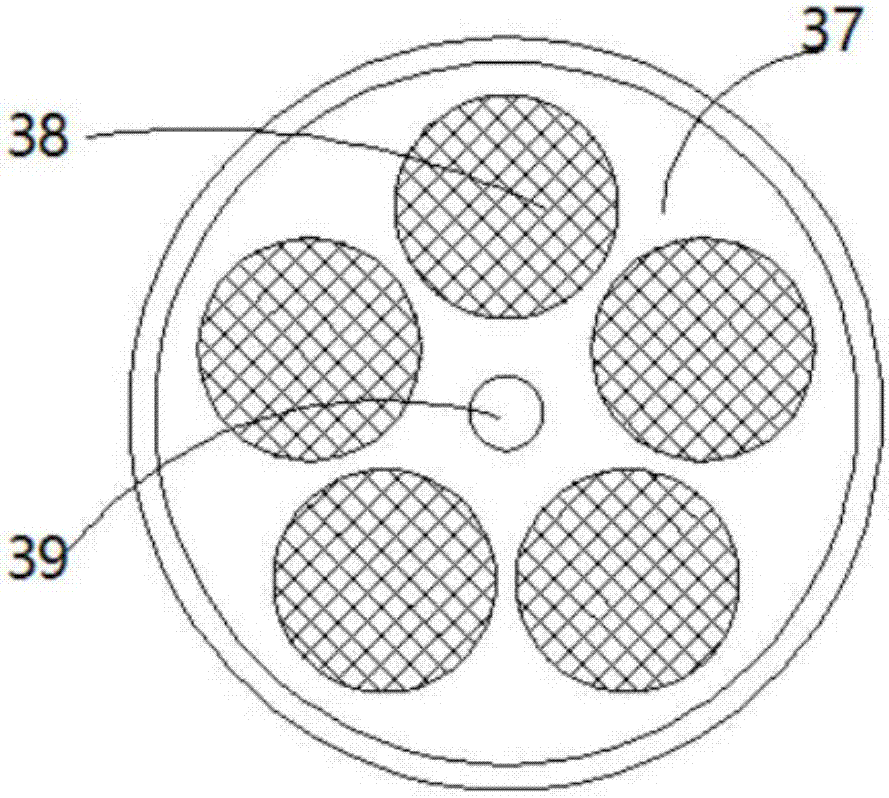

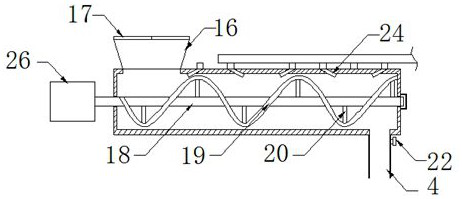

Horizontal type screw rod structure cracking furnace for waste tire resource recycling

InactiveCN104357077AShorten the production cycleIncrease heat transfer areaPigmenting treatmentPlastic recyclingSpiral bladeRetention time

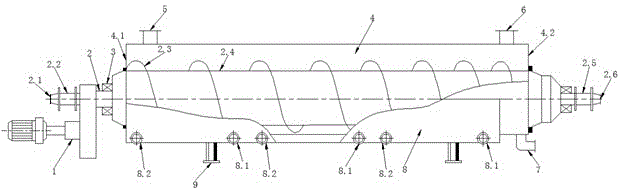

The invention discloses a horizontal type screw rod structure cracking furnace for waste tire resource recycling. The horizontal type screw rod structure cracking furnace comprises a sealed furnace body, wherein a tire block inlet tube and a cracking gas outlet tube are respectively arranged on the left side of the upper part and the right side of the upper part of the furnace body; the furnace body is internally provided with a rotor; two ends of the rotor are respectively supported in a left bearing support and a right bearing support; the rotor is driven to rotate through a transmission system at the left end of the rotor; a heating jacket is arranged at the lower part of the outer side of the furnace body; a cracking product outlet tube is arranged at the lower part of the right end of the furnace body; the whole device is mounted on a saddle support. A heat source is provided by virtue of a hollow shaft and the jacket together, so that a great heat conduction area is achieved; separated cracking products can be used as the heat source; the high-temperature gas inside the hollow shaft and the jacket flows in a countercurrent manner, the jacket only wraps a lower cylinder and contacts a cracking reaction position, multi-stage serial connection is adopted, and baffle plates are arranged inside the jacket, so that the retention time of the high-temperature gas is prolonged; the screw pitches of spiral blades are spare in the front part and dense in the rear part, the cracking products are completely discharged outside the cylinder along with rotation of the spiral blades, and shutdown operation is not required.

Owner:ZHEJIANG UNIV

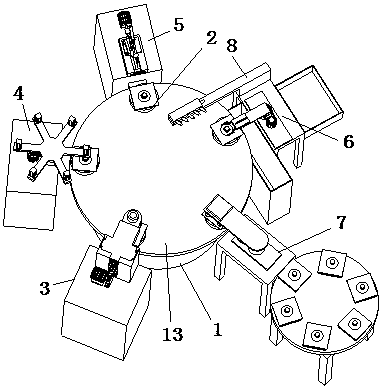

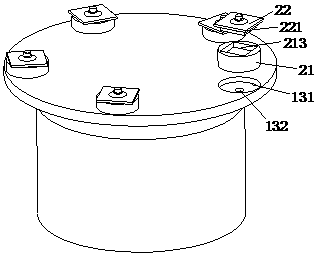

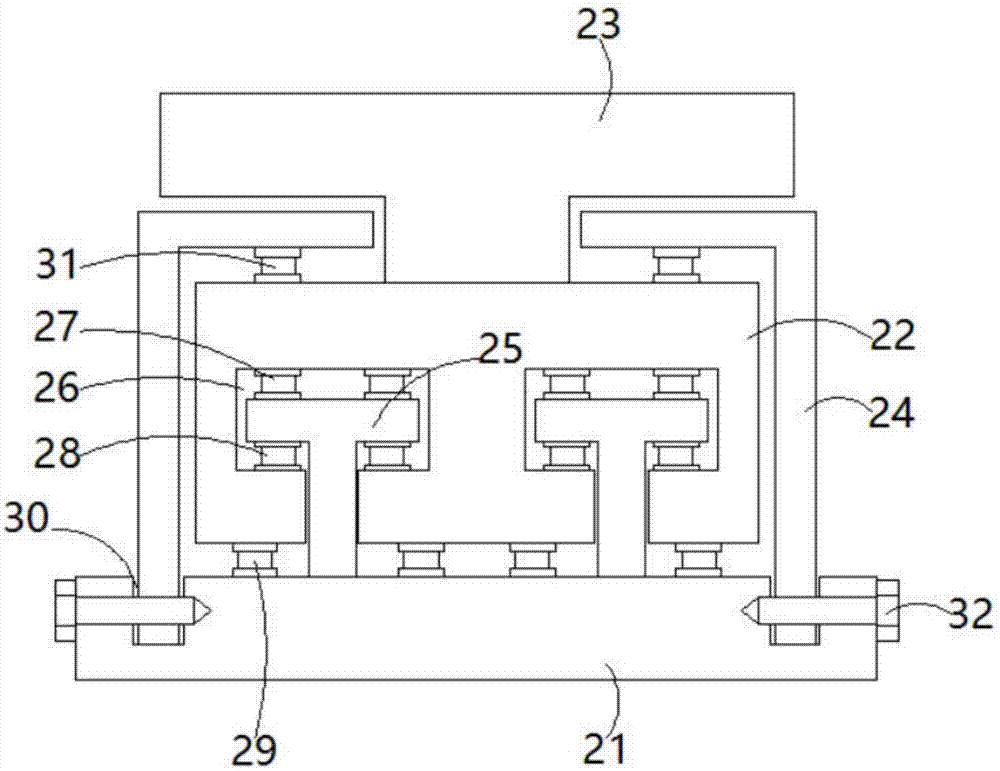

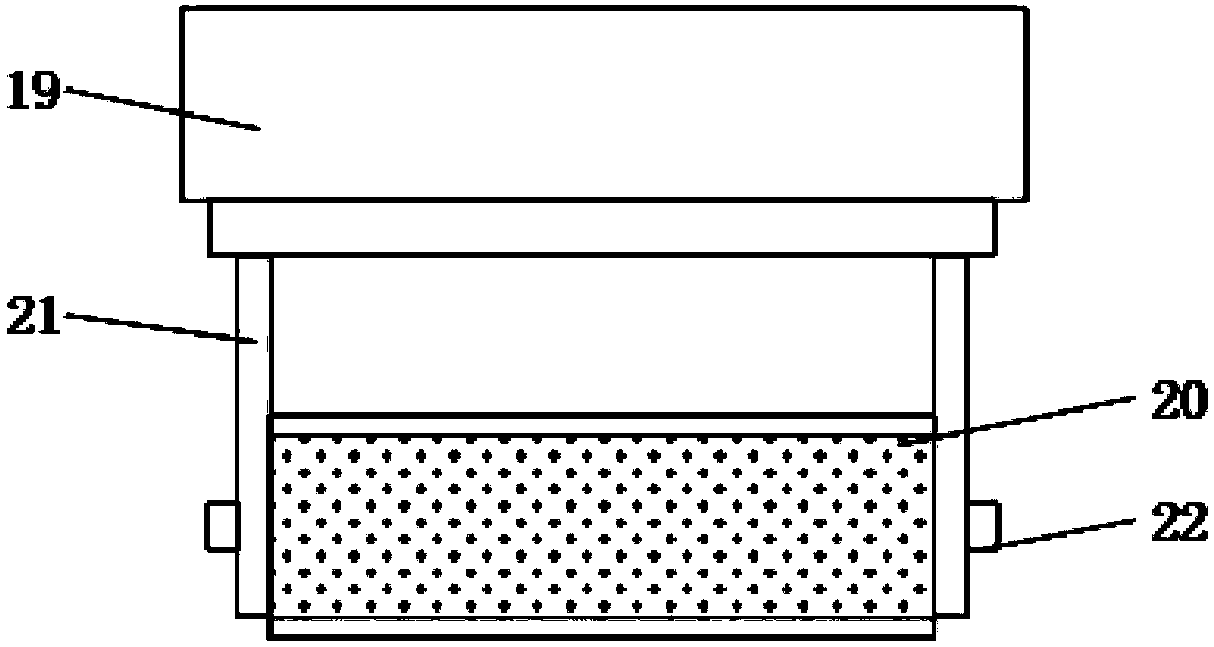

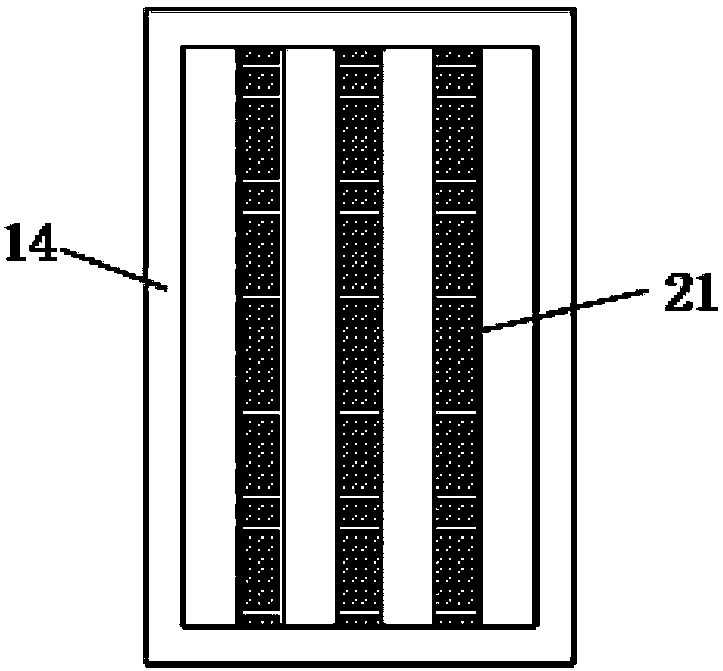

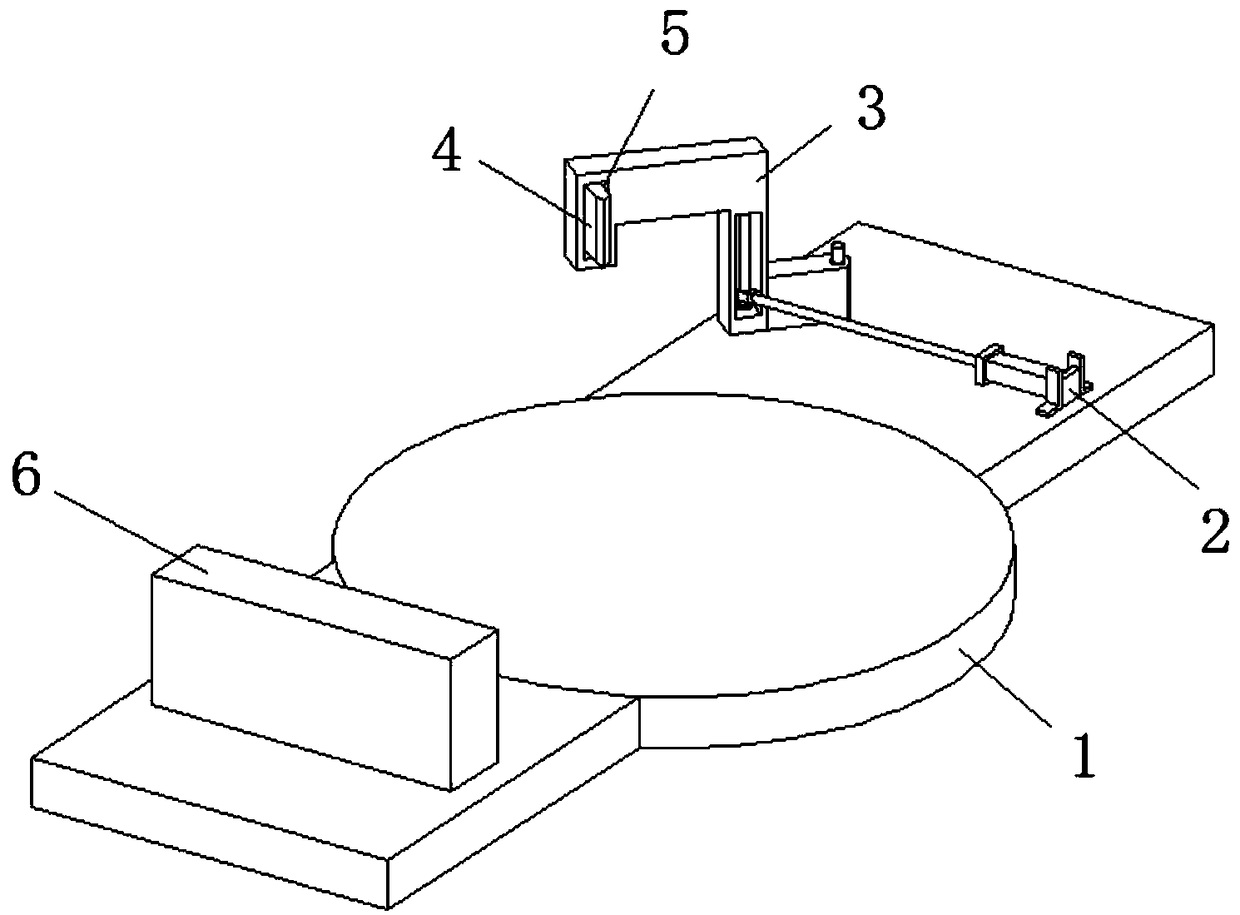

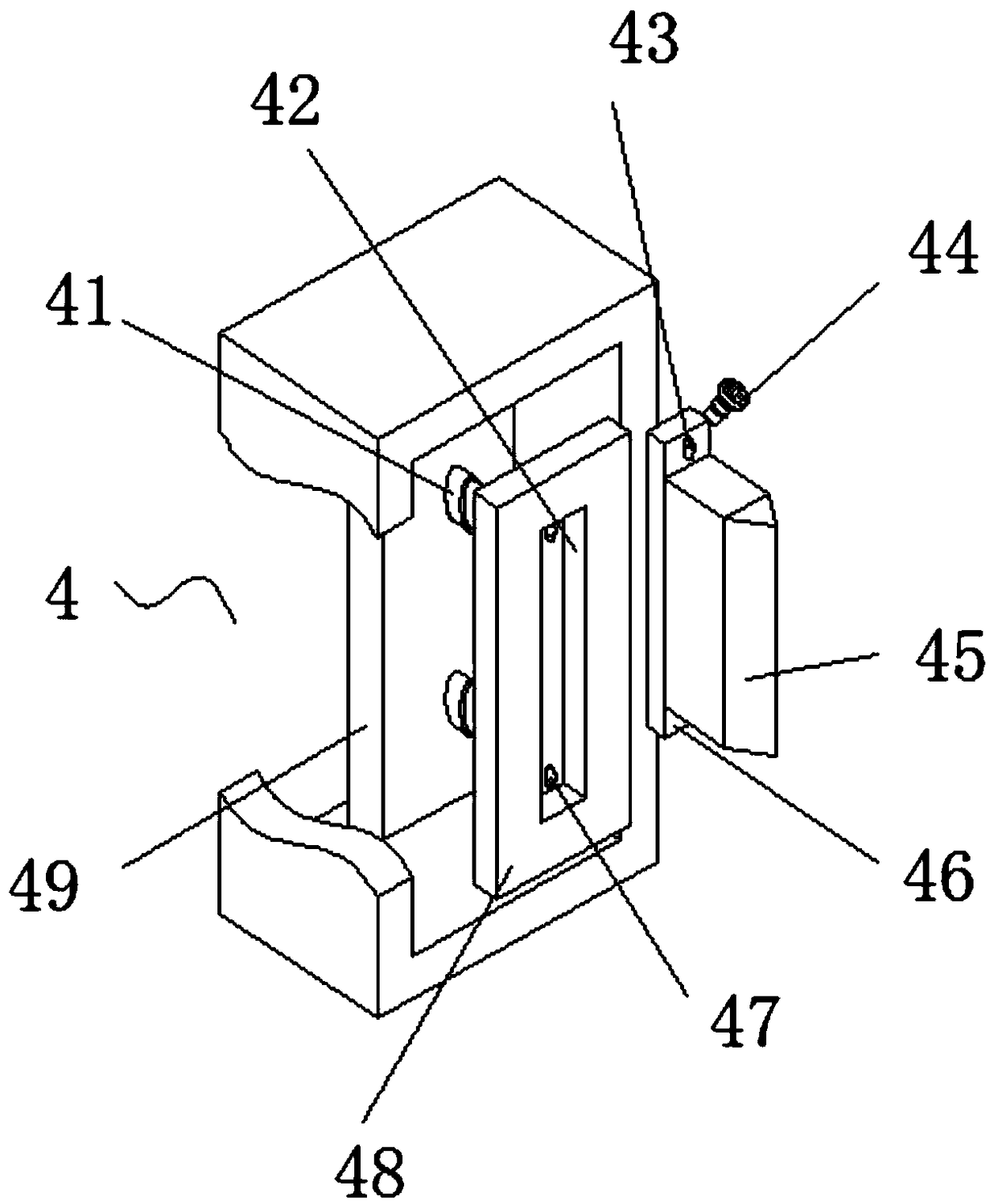

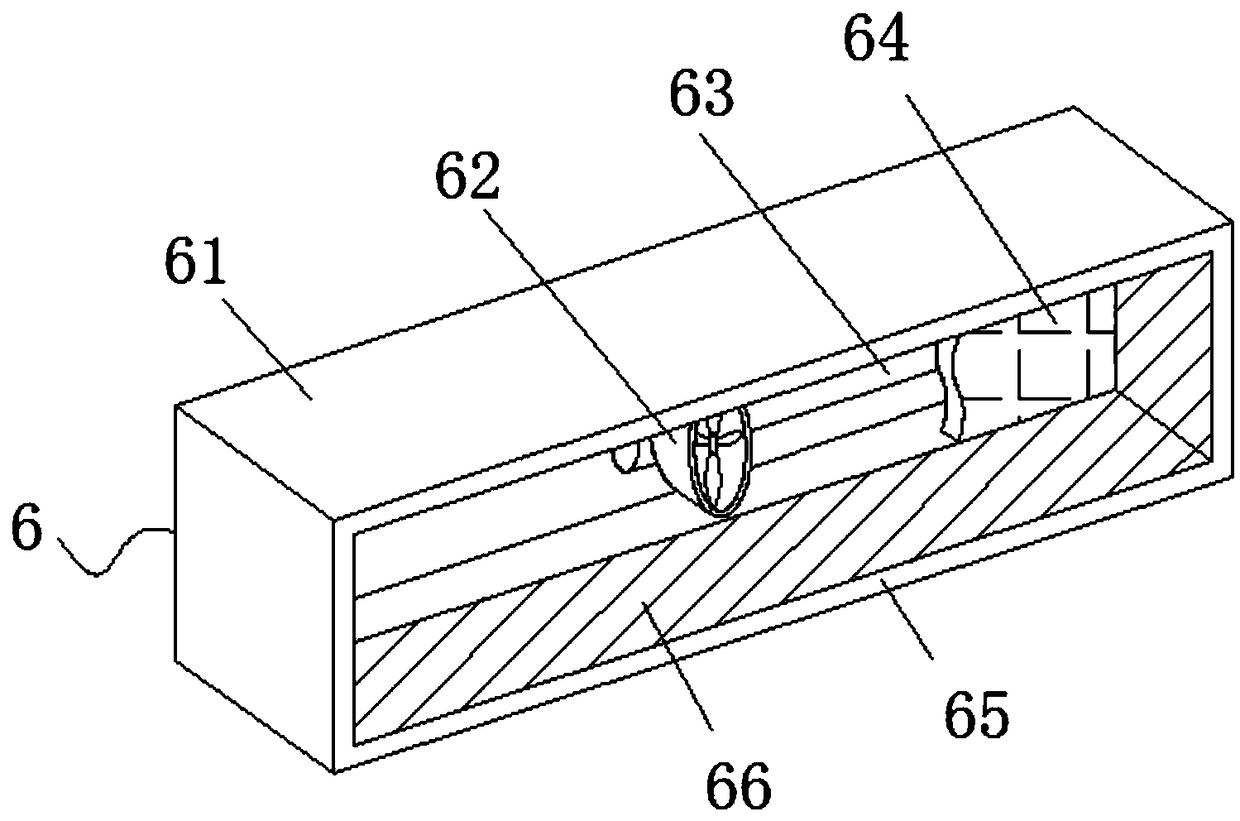

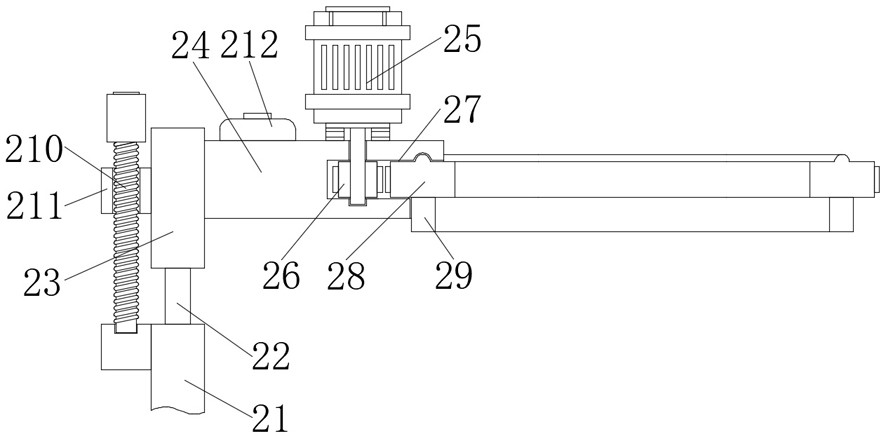

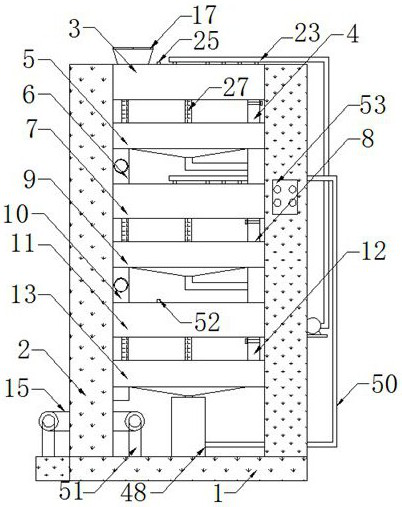

Environment-friendly rubber O-shaped ring material processing device

InactiveCN110815676APrevent fallingRealize automatic trimming operationDomestic articlesMetal working apparatusCouplingElectric machinery

The invention relates to the field of rubber O-shaped ring machining equipment, in particular to an environment-friendly rubber O-shaped ring material processing device. The environment-friendly rubber O-shaped ring material processing device comprises a processing table, wherein a first coupling seat is arranged at the top of the processing table, the top of the first coupling seat is provided with a vertically arranged first rotating shaft, a first rotating disc coaxial with the first rotating shaft is arranged at the top of the first rotating shaft, and five fixing fixtures evenly distributed in the circumferential direction of the first rotating disc are arranged on the first rotating disc; a stepping motor is arranged in the processing table, and the output end of the stepping motor is connected with the first coupling base; and a feeding mechanism, a material pressing mechanism, an edge trimming mechanism, a discharging mechanism and a jig replacing mechanism are sequentially arranged in the rotating direction of the first rotating disc, and a waste cleaning mechanism is arranged on the discharging mechanism. According to the environment-friendly rubber O-shaped ring materialprocessing device, automatic edge trimming work is carried out on rubber O-shaped rings, a jig can be automatically replaced without shutdown, and the edge trimming efficiency of the rubber O-shapedrings is improved.

Owner:王伟

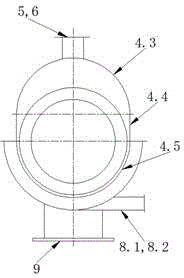

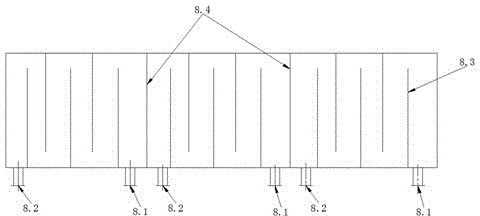

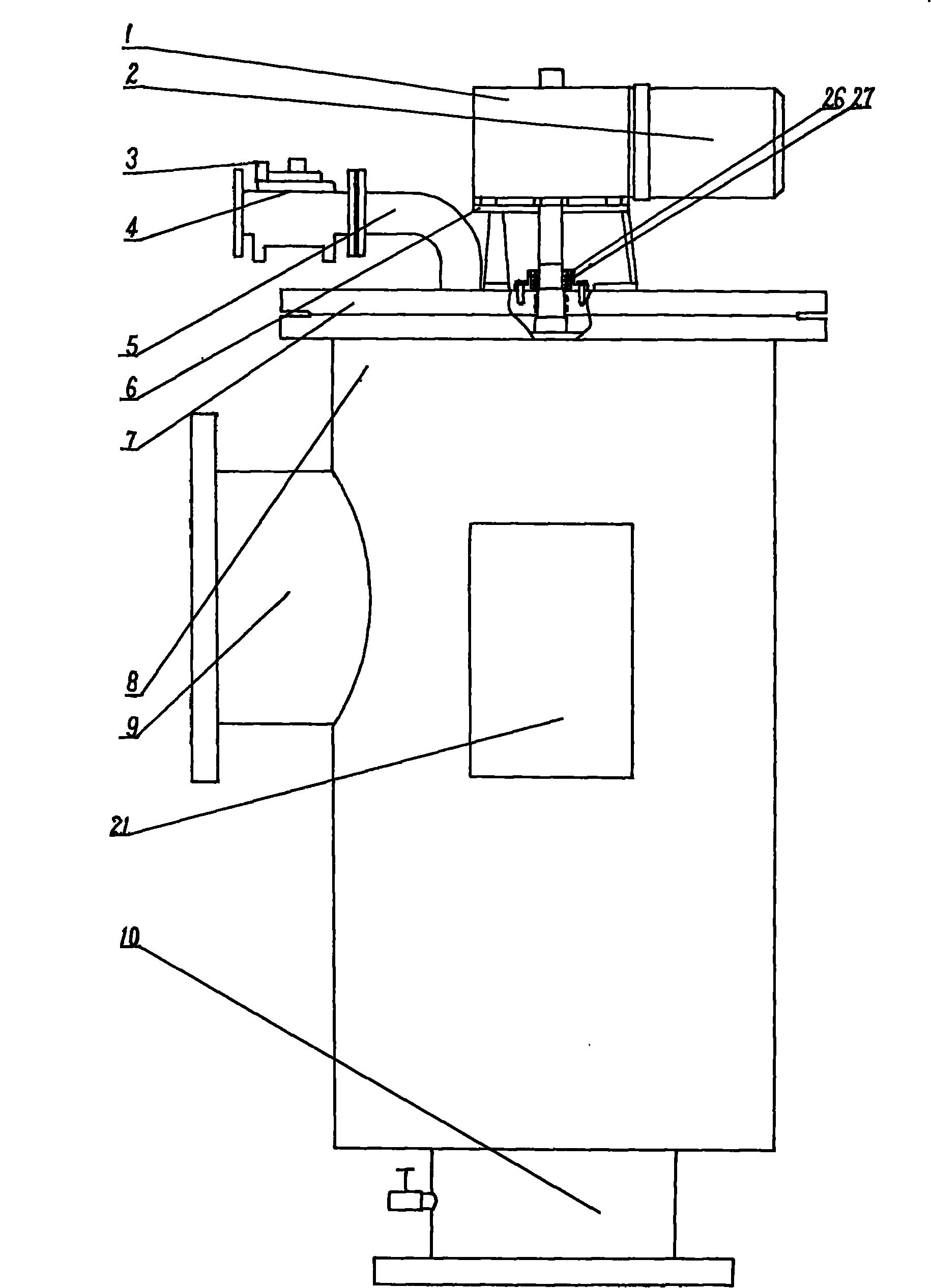

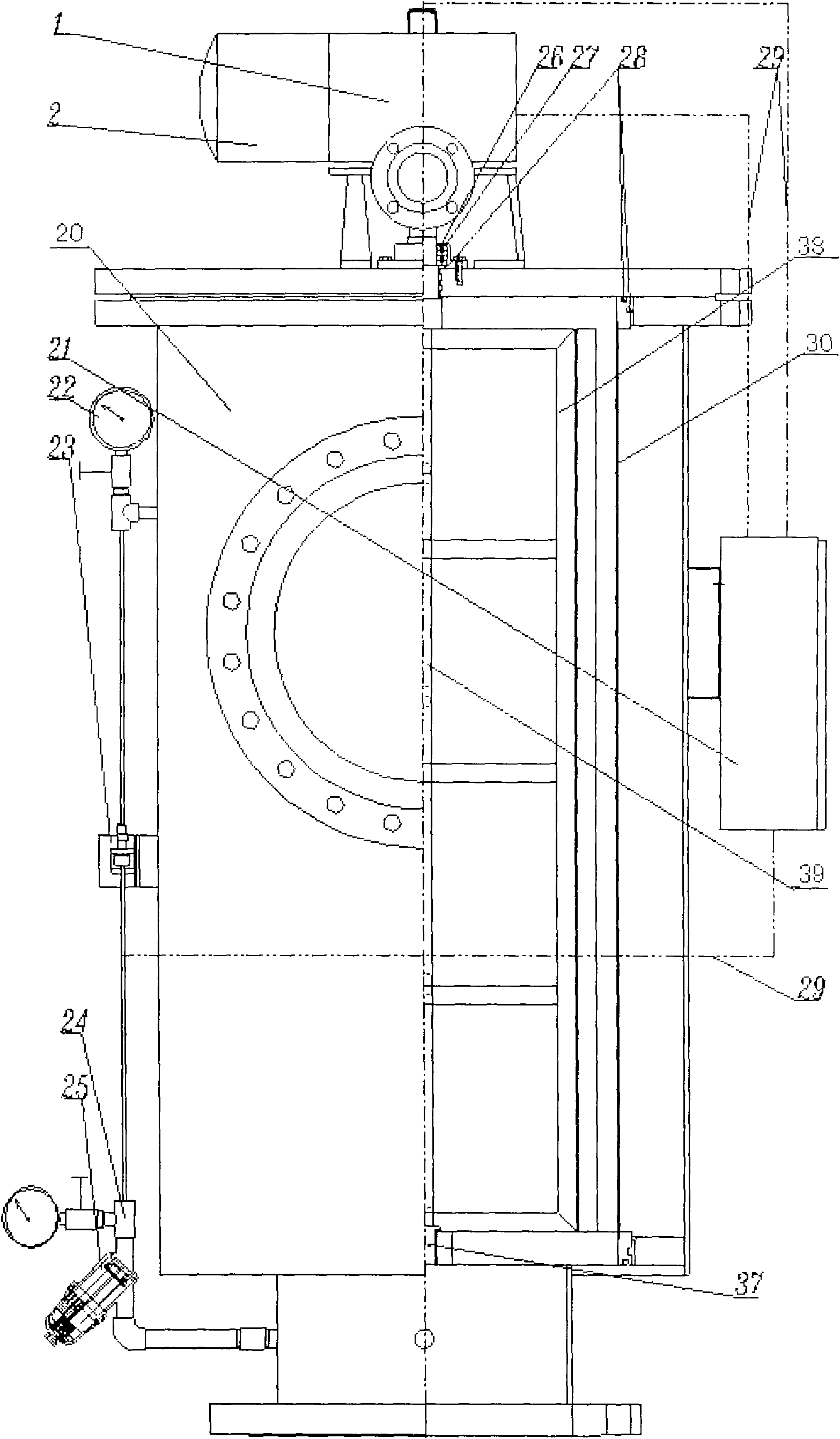

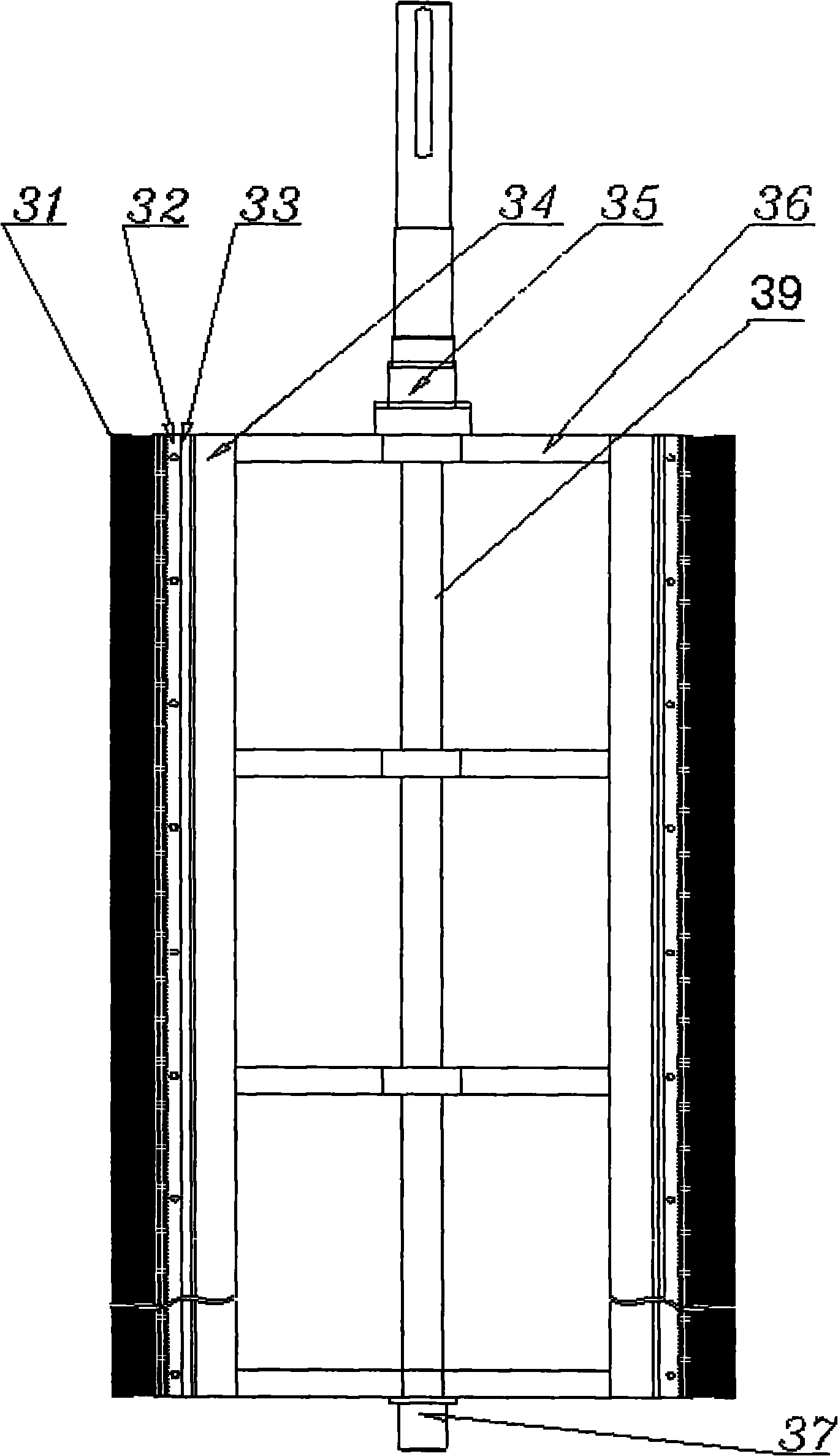

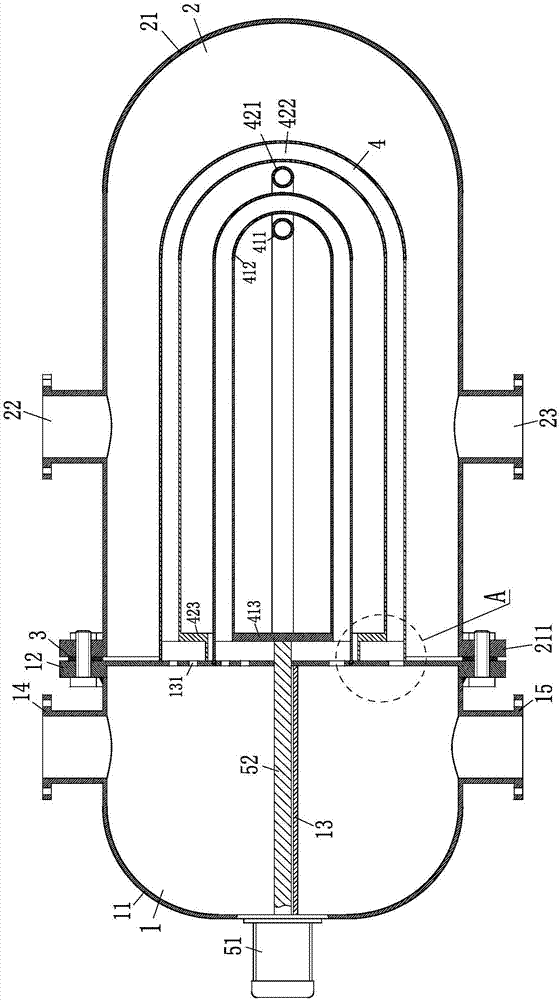

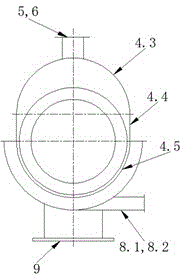

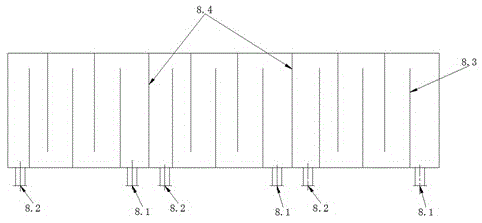

Bulk flow and self-cleaning net type filter

InactiveCN102039065AHigh degree of automationFiltration flow is largeStationary filtering element filtersControl systemSewage

The present invention relates to a bulk flow and self-cleaning net type filter comprising a tank body, a power system, a control system and a filter chamber. The bottom of the tank body is provided with a water inlet, one side of the tank body is provided with a water outlet, and the top of the tank body is provided with a sewage draining exit and a power system, and a filter chamber connected with the power system, the control system and the water outlet respectively is arranged inside the tank body. The filter is characterized in that the filter chamber comprises a cuneate filter canister and a rotating stainless steel wire brush unit arranged in the cuneate filter canister; the cuneate filter canister is connected with the water inlet; the rotating stainless steel wire brush unit comprises central upper, middle and lower wire brush shafts that are connected to each other, and three sets of steel wire brushes that are arranged at the central brush shafts vertically; the upper and lower shafts of the wire brush are connected with the top and the bottom of the filter chamber respectively; every two steel wire brushes are at a 120 DEG angle to each other. The filter is advantageous in simple structure, sensitive self-cleaning control system and excellent sewage draining effect.

Owner:GANSU DAYU WATER SAVING

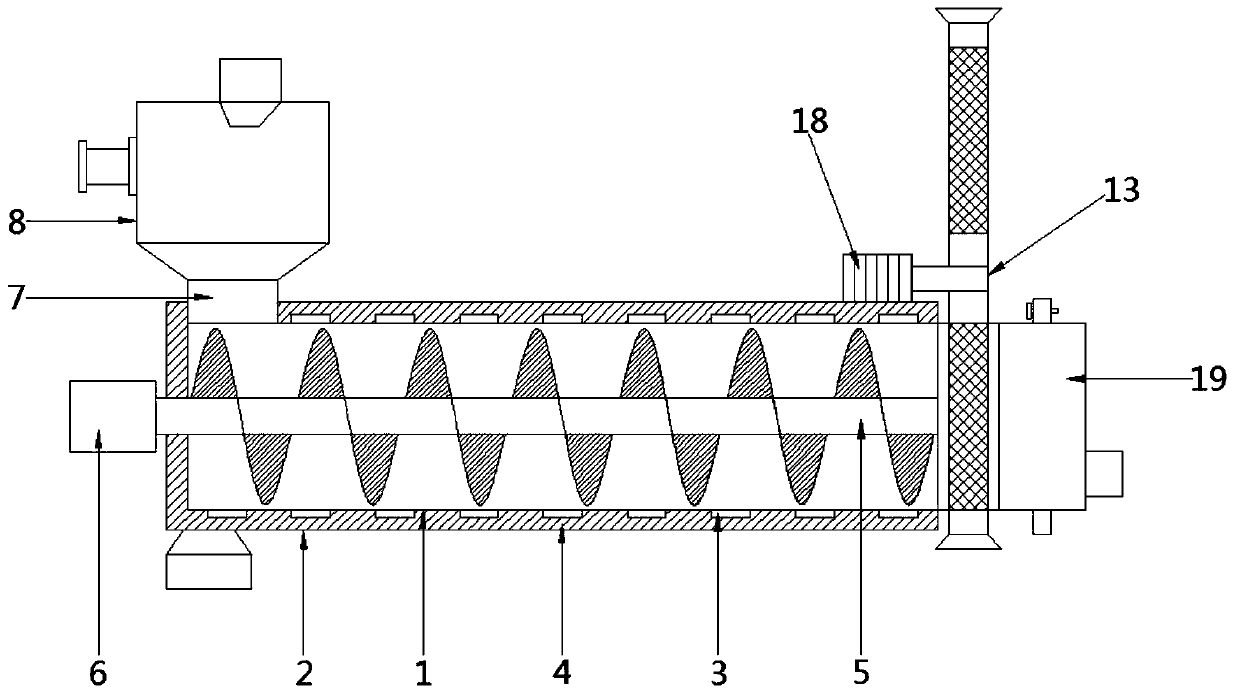

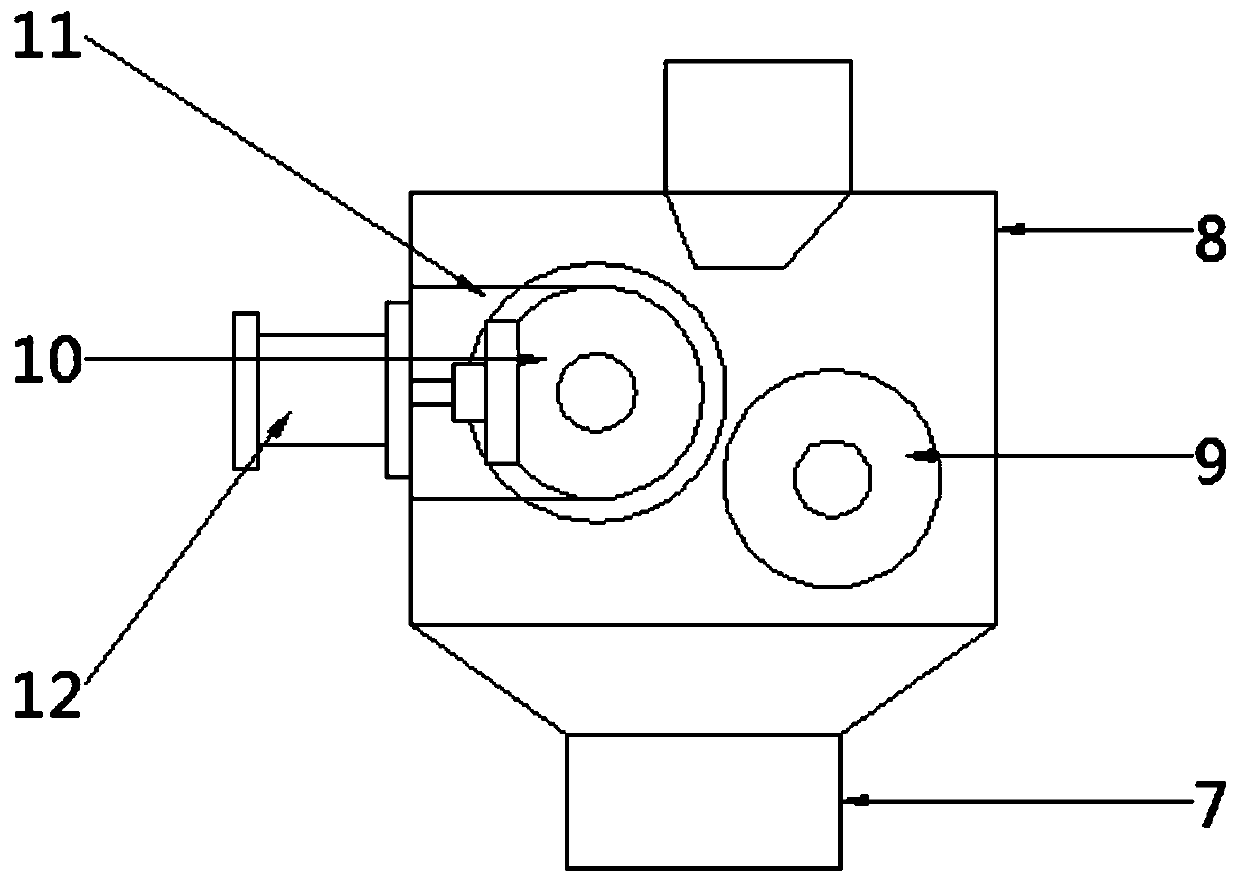

Hot melt extruder for thin film packaging material processing

InactiveCN107031010AAvoid cakingEasy extrusionNon-rotating vibration suppressionFlat articlesSolenoid valveCooling effect

The invention discloses a hot melt extruder for thin film packaging material processing. The holt melt extruder comprises a machine body which is a horizontally arranged cylinder, wherein an inner barrel is arranged inside the machine body; the inner barrel and the machine body are coaxially arranged; a material bin is arranged at the left upper side of the machine body; the bottom end of the material bin is connected with an unloading tube which is vertically arranged; a feeding connector is arranged at the upper side inside the unloading tube; and the feeding connector comprises a screw, a screw blade arranged on the outer wall of the screw and a motor connected with the screw. The hot melt extruder for thin film packaging can be used for continuously and uniformly feeding without a blocking phenomenon, can pre-pulverize raw materials, effectively improves extruding efficiency, can replace an extrusion mould head without stop, is convenient to clean and replace, an does not need manual operation; cooling speed in an extruding device can be controlled through a solenoid valve and a temperature sensor, so that the cooling effect is guaranteed; besides, the vibration reducing effect is good, the positioning effect is good, working stability of the extruder is improved, and noises generated by vibration are effectively reduced.

Owner:湖州多玛智能科技股份有限公司

Nap removal device for towel decorating machine

The invention relates to the technical field of nap removal devices, and particularly relates to a nap removal device for a towel decorating machine. The nap removal device comprises an operating platform, a driving motor, a positioning plate, a blast blower and an electric hydraulic cylinder, wherein a bracket is mounted at a bottom end of the operating platform; fixing plates are arranged on a left side and a right side of an upper end of the operating platform; a first rotating shaft is arranged at the center of the fixing plate; a driving wheel is arranged on an outer ring of a first rotating shaft on the left side; a driven wheel is arranged on the outer ring of the first rotating shaft on the right side; the driving motor is mounted on the left side of the driving wheel; a connectingrod is arranged on the driving motor; the other end of the connecting rod is connected to the first rotating shaft on the left side; a conveyor belt is connected between the driving wheel and the driven wheel; upright columns are mounted on an upper end surface of the operating platform; the positioning plate is mounted between the upright columns; and a control switch is arranged at the center of the front surface of the positioning plate. The nap removal device has advantages of relatively good integral stability, simple structure, relatively good nap removal effect, low cost and convenientoperation, and has a certain promotion value.

Owner:HAINING KUCAI DIGITAL TECH CO LTD

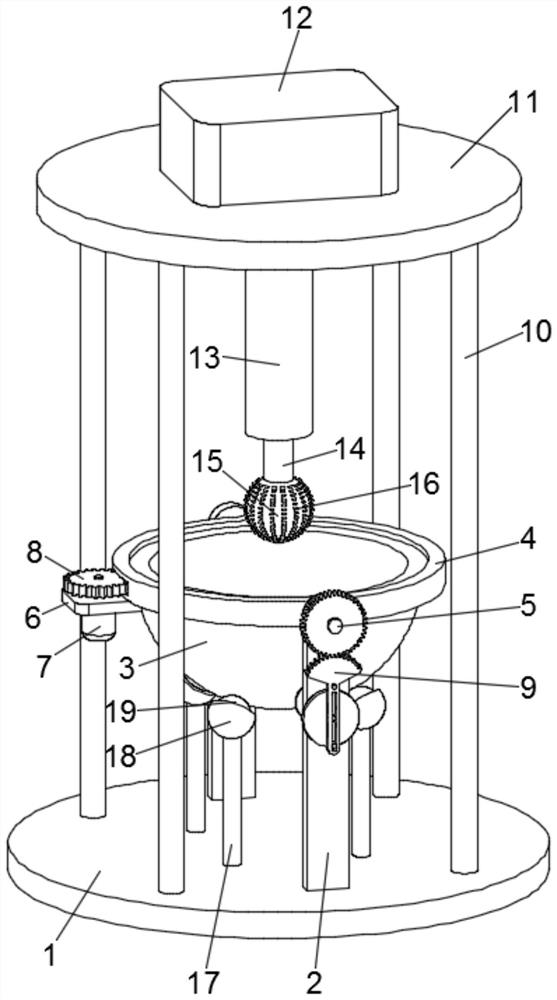

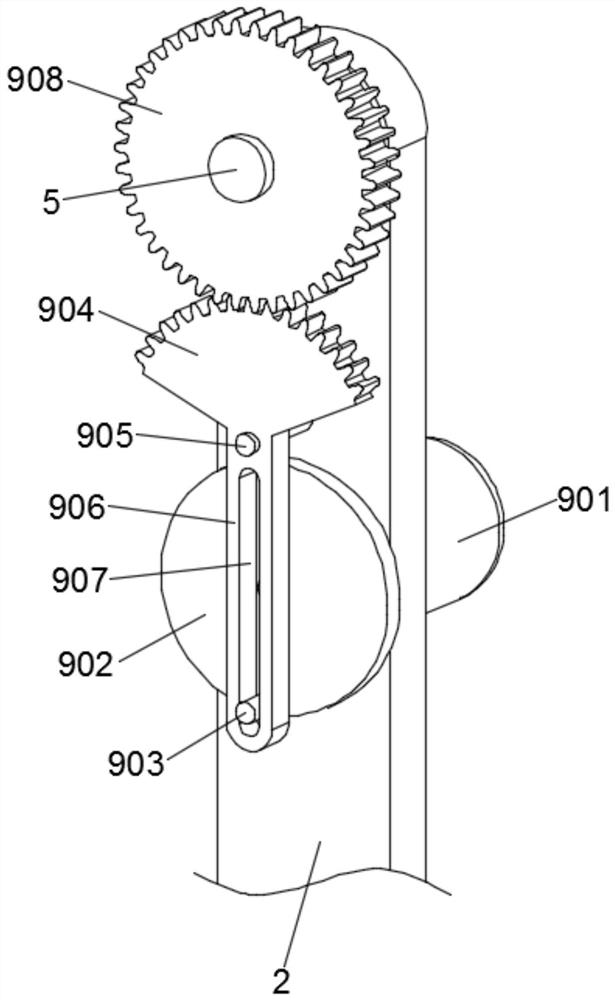

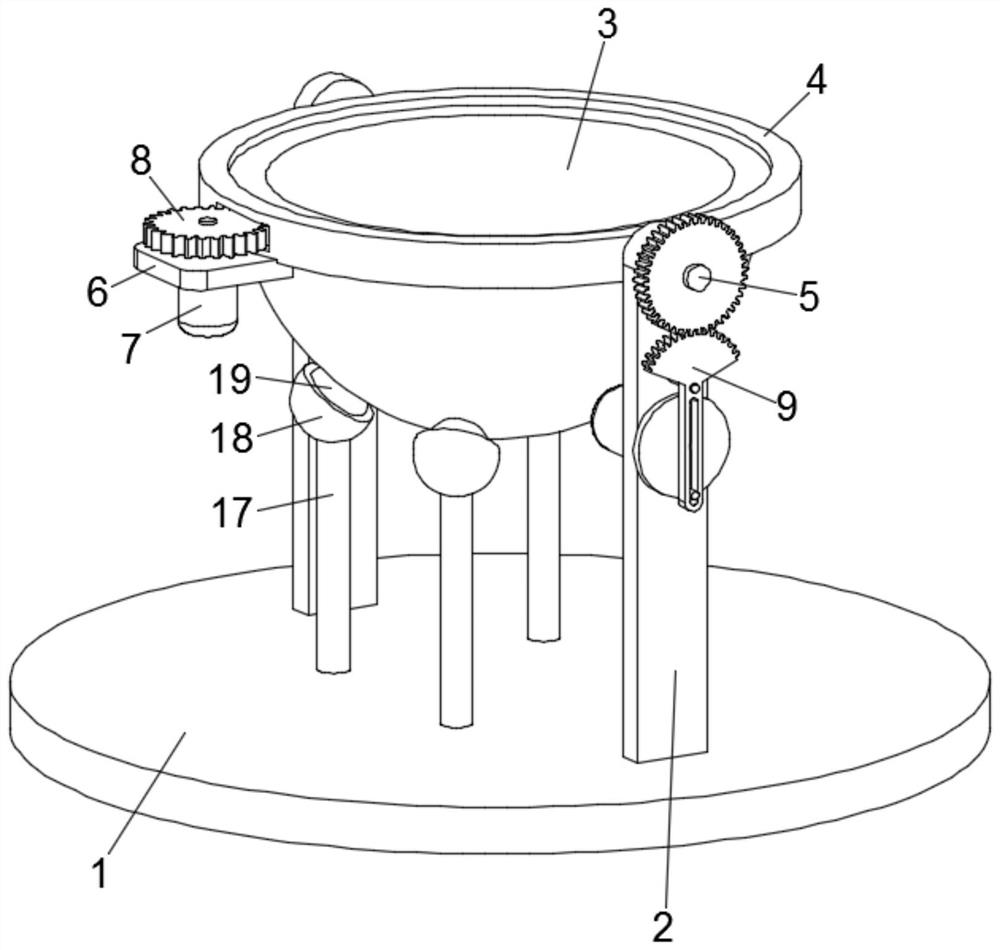

Beating device for food processing

InactiveCN112042696AFully artificialNo resistanceMeat processingFood shapingReciprocating motionElectric machine

The invention discloses a beating device for food processing. The beating device comprises a base, supporting frames and a material containing groove, wherein the two supporting frames are verticallyfixed on the base; an annular sleeve is rotationally arranged outside the edge of the upper end of the material containing groove in a sleeving mode; the annular sleeve is rotationally installed at the upper ends of the supporting frames; a rotating motor is arranged on the annular sleeve; a first gear is rotationally installed on the rotating motor; an annular gear ring is arranged on the edge ofthe upper end of the material containing groove; a swinging mechanism for driving the annular sleeve to swing in a reciprocating mode is further arranged on the supporting frame on one side; and a plurality of supporting assemblies are uniformly distributed on the base in the circumferential direction. According to the beating device for food processing, the material containing groove is driven to rotate in the circumferential direction and swing in a left-right reciprocating mode through the rotating motor and the swinging mechanism, meanwhile, a hammer head is driven by a press machine to move up and down in a reciprocating mode, food in the material containing groove is repeatedly beaten, so that the hammer head can act on each area on the inner wall of the material containing groove,the food in each area is beaten, dead angles are avoided, shutdown operation is not needed, the processing beat is not delayed, and the beating efficiency is high.

Owner:吕瑞雪

Self-cleaning intelligent factory wastewater purification treatment equipment

InactiveCN114733251AImprove filtration efficiencySlow down the flowMoving filtering element filtersReciprocating motionProcess engineering

The invention relates to the technical field of wastewater treatment accessory devices, in particular to self-cleaning intelligent factory wastewater purification treatment equipment which comprises a horizontally-arranged bottom plate. The filtering mechanism comprises a filtering cylinder internally provided with a cavity, the left end of the filtering cylinder communicates with a water inlet pipe, a rotating shaft is rotationally arranged on the right wall in the filtering cylinder, a spiral net plate is arranged on the rotating shaft, a moving plate is slidably arranged on the spiral face of the spiral net plate, and a rubber scraping strip is arranged on the side, close to the spiral net plate, of the moving plate; a reciprocating motion mechanism is arranged on the filter cylinder body; the water pumping mechanism comprises a middle cylinder internally provided with a cavity, the water inlet pipe is communicated with the left end of the middle cylinder, the right end of the middle cylinder is communicated with a connecting pipe, the connecting pipe is provided with a water pump, and the middle cylinder is provided with a driving mechanism. The filtering assembly is automatically cleaned in the wastewater filtering process, operation is easy, shutdown operation is not needed, and the wastewater purification treatment efficiency is high.

Owner:太仓贻科环保科技设备有限公司

Film cutting mechanism of film winding machine

InactiveCN108792745AImprove film cutting efficiencySimple structureArticle deliveryWebs handlingWinding machineEngineering

The invention discloses a film cutting mechanism of a film winding machine. The mechanism comprises a base, a first air cylinder is arranged on one side of the base, a z-shaped rotating arm is arranged at the output end of the first air cylinder, a groove is arranged on one side, far away from the first air cylinder, of the z-shaped rotating arm, the film cutting mechanism is arranged in the groove, and a dust removal mechanism is arranged on one side, far away from the first air cylinder, of the base. The film cutting mechanism has the advantages that the draught fan is started, so that a negative pressure area is formed in the interior of a dust removal shell, waste materials generated in the film cutting process can be effectively sucked into the waste collecting box, the waste materials entering into the waste collecting box adhere to the surface of a viscous layer through the negative pressure effect, the structure is simple, the practicability is high, the waste materials generated in the film cutting process can be prevented from influencing the film cutting mechanism, the generated waste materials can be comprehensively cleaned through the draught fan to be displaced underthe action of the third air cylinder, the cleaning operation does not require shutting down the film cutting mechanism and the film cutting efficiency of the film cutting mechanism is improved therefore.

Owner:福州通立工业设计有限公司

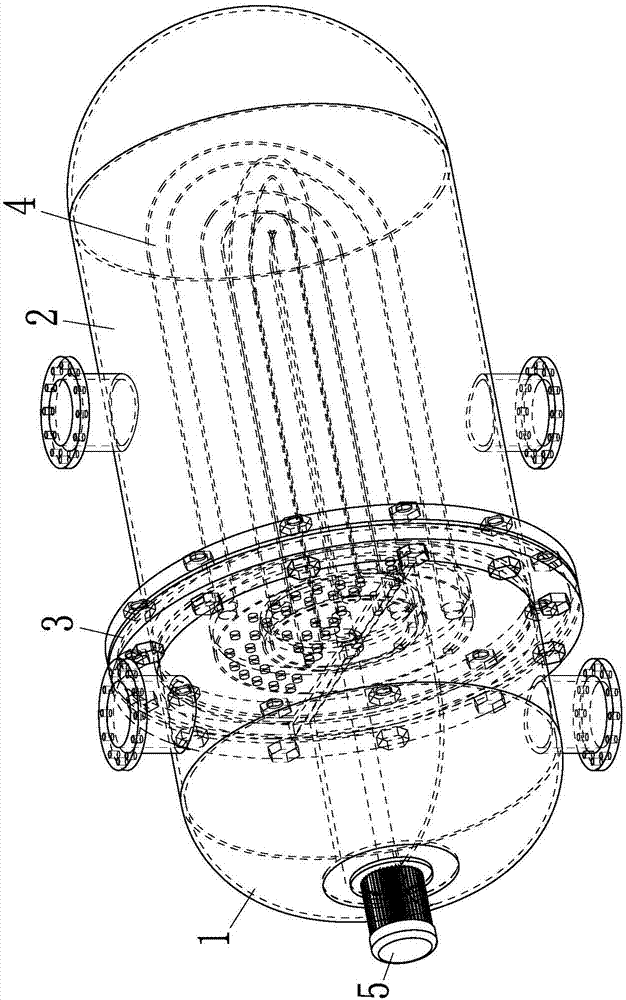

A Difficult-to-Scale Reboiler for Alcohol Production

ActiveCN106267858BAvoid corrosionWon't hurtBoiling apparatusFractional distillationReboilerAlcohol production

The invention relates to the field of alcohol production equipment, in particular to a hard-to-scale reboiler for alcohol production, comprising an air inlet area, a reboiler area, a gasket, a heating tube group and a transmission device, and the air inlet area includes an inlet Gas hood, mounting plate, partition plate, inlet pipe and liquid outlet pipe; the reboiler zone includes a reboiler hood, a gasification outlet pipe and a liquid outlet pipe; the heating pipe group includes a first pipe group and a liquid outlet pipe. The second pipe group, the first pipe group includes the No. 1 pipe, the No. 2 pipe and the first pipe cover; the second pipe group includes the No. 3 pipe, the No. 4 pipe and the second pipe cover; the The transmission device includes a main shaft and a rotating motor. The heating tube group of the present invention is not easy to form fouling, effectively avoids corrosion to the wall of the heating tube of the reboiler, and does not damage the inner wall of the heating tube.

Owner:ANHUI ANTE FOOD

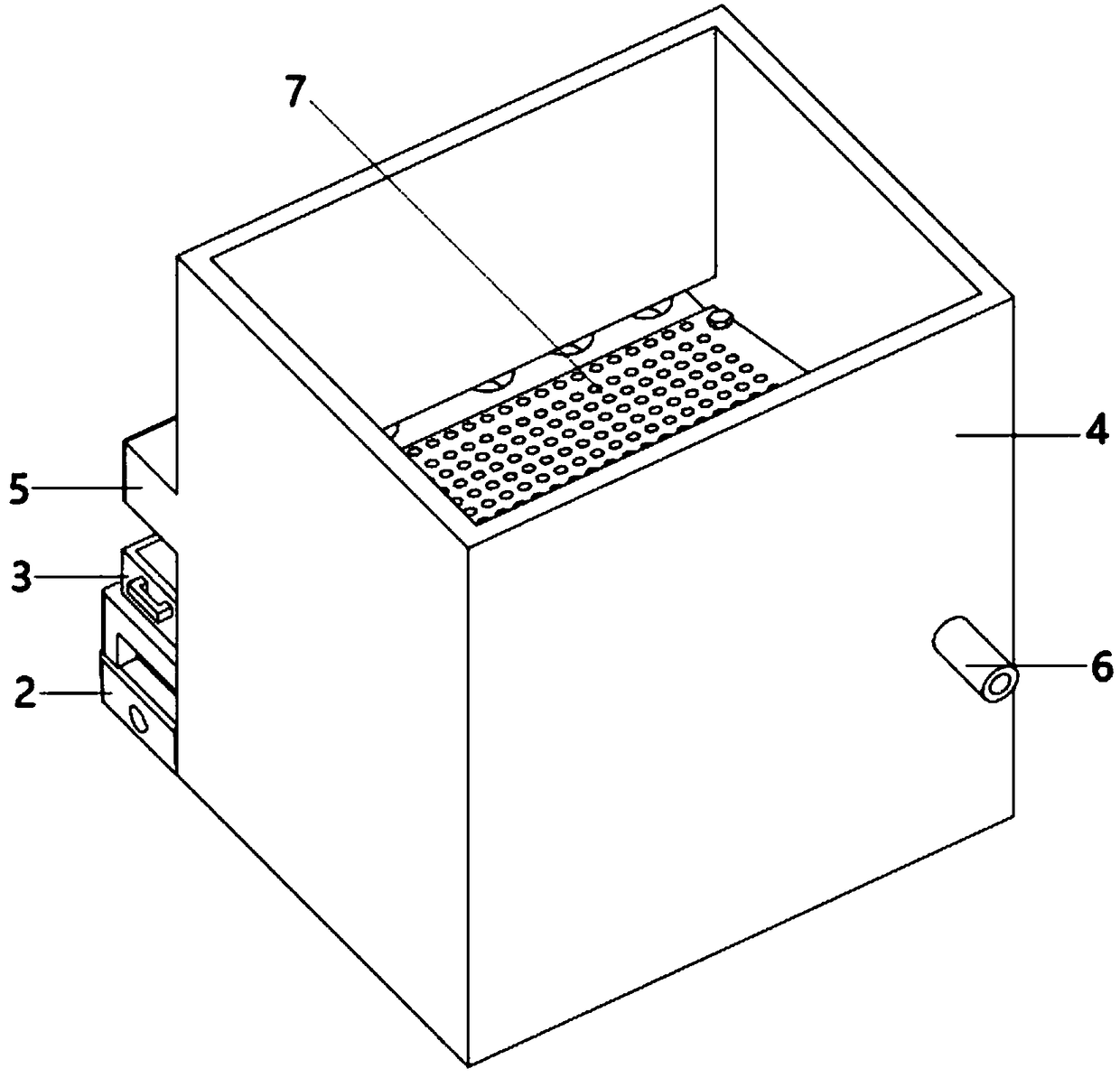

Easily cleaned thermal treatment quenching tank

InactiveCN108251619AImprove the effect of physical slag removalEasy dischargeProcess efficiency improvementQuenching devicesQuenchingThermal treatment

The invention provides an easily cleaned thermal treatment quenching tank which comprises a circulation liquid discharge tank, a residue cleaning box and a quenching tank, wherein a residue cleaning box holding rack is arranged on the upper side of the circulation liquid discharge tank; the residue cleaning box is mounted at the top of the residue cleaning box holding rack in an embedded manner; aresidue discharge pipeline is arranged on the lower side of a residue collection tank; a filtering net plate mounting rack is arranged on the inner side of the quenching tank; a filtering net plate is fixed on the filtering net plate mounting rack through bolts. The filtering net plate which is of inclined structural design is arranged in the easily cleaned thermal treatment quenching tank, the filtering net plate is inclined towards the residue collection tank, in addition, and the inclined bottom end of the filtering net plate is arranged at the upper end of the bottom surface of the residue collection tank, so that due to the structure, residues can slide into the inner side the residue collection tank through the inclined filtering net plate through continuous vibration of a coolant,and are further discharged out through the residue discharge pipeline, and the physical residue cleaning effect of residues can be effectively improved.

Owner:HUBEI ZANBO INFORMATION TECH CO LTD

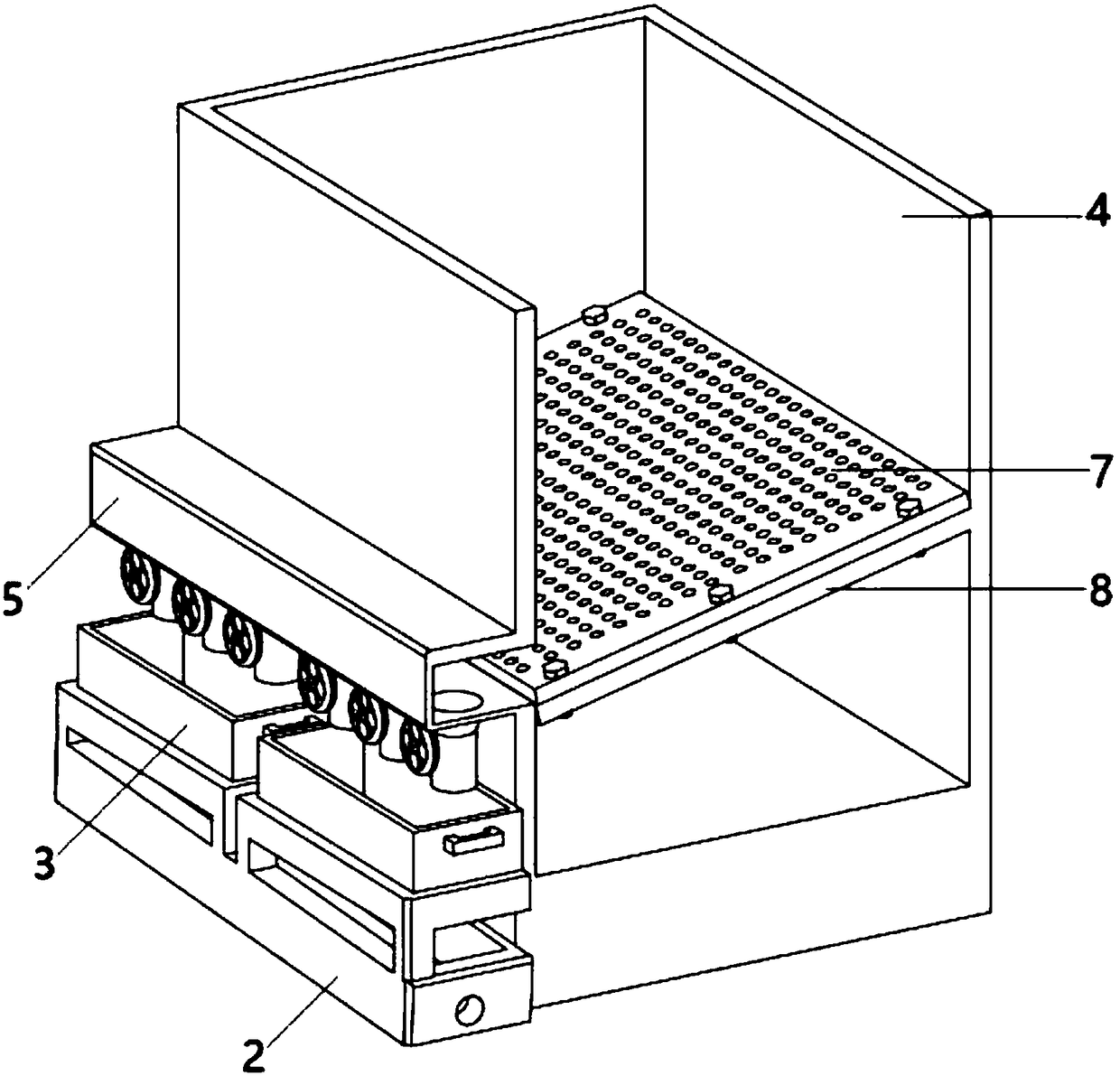

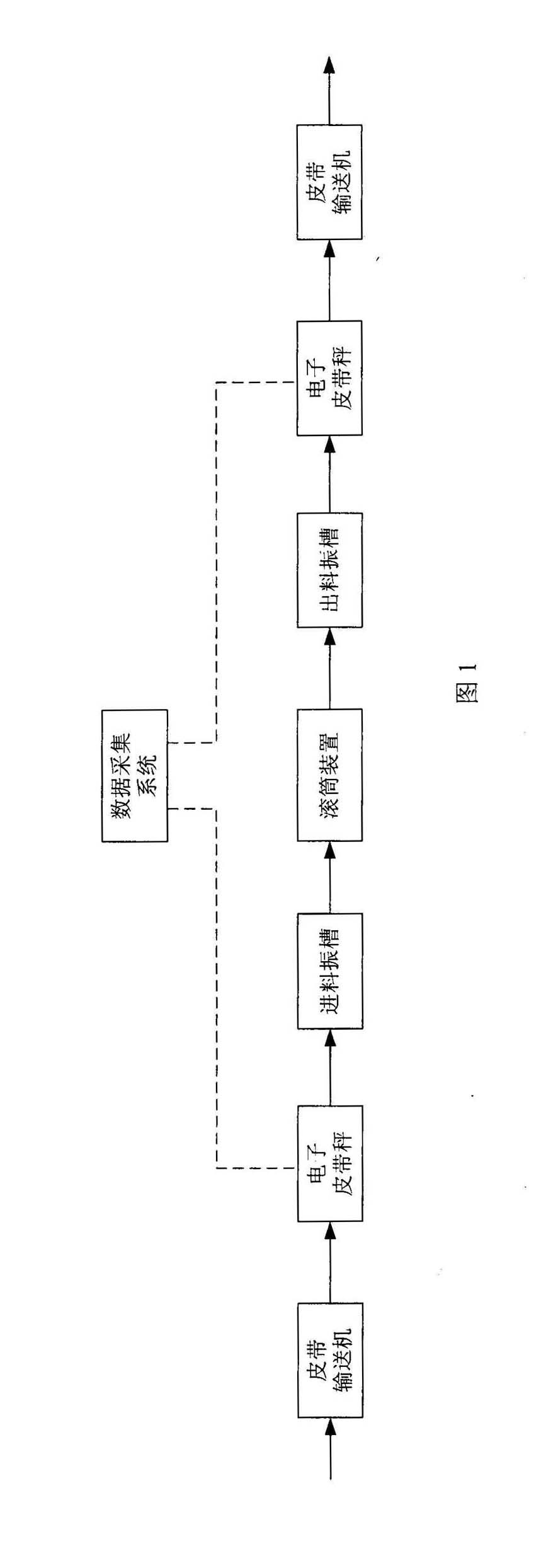

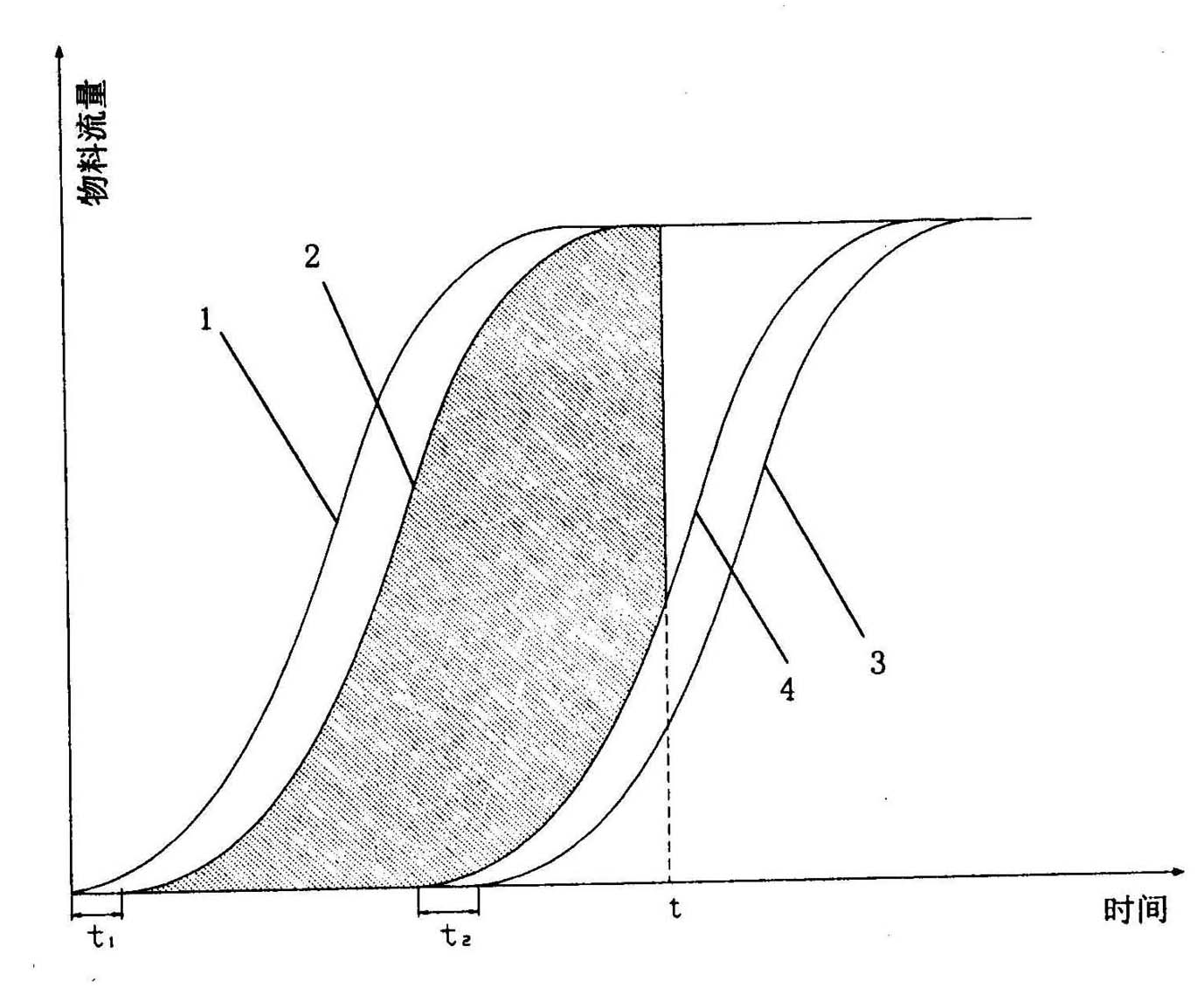

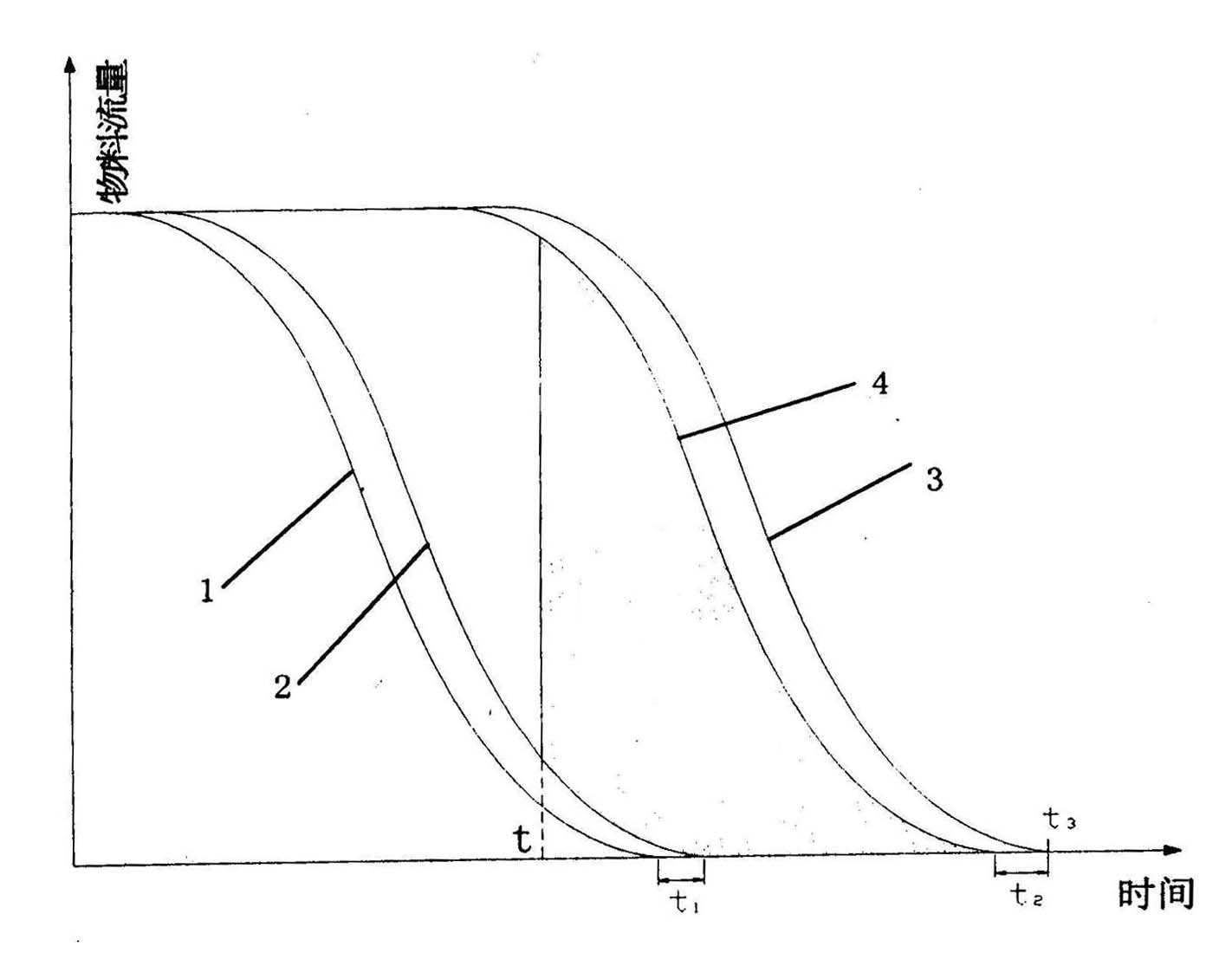

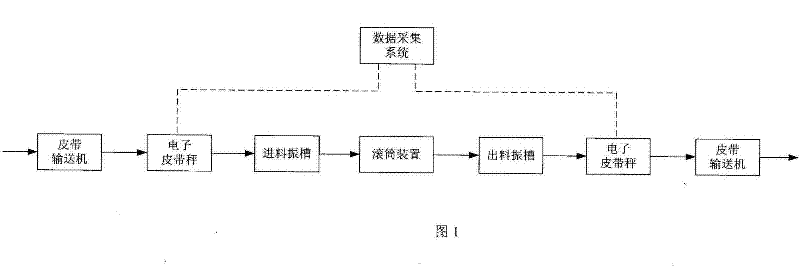

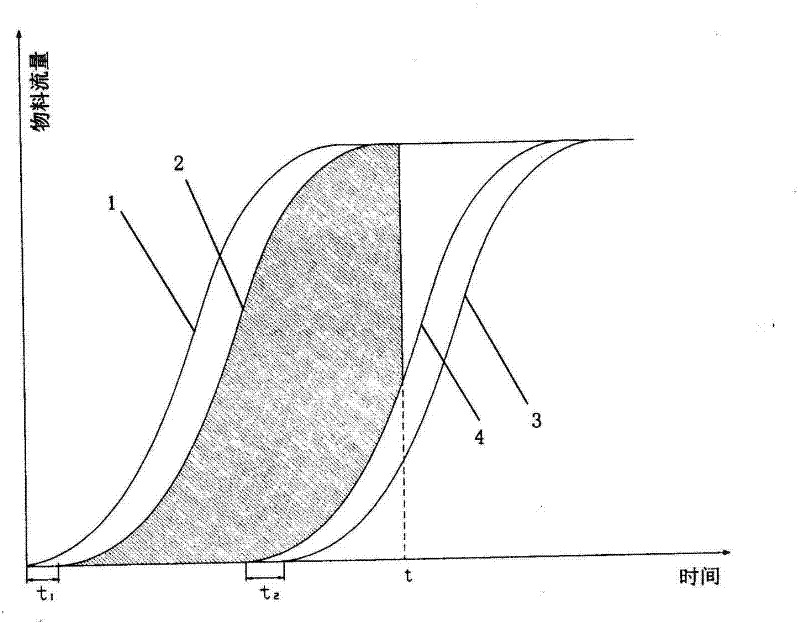

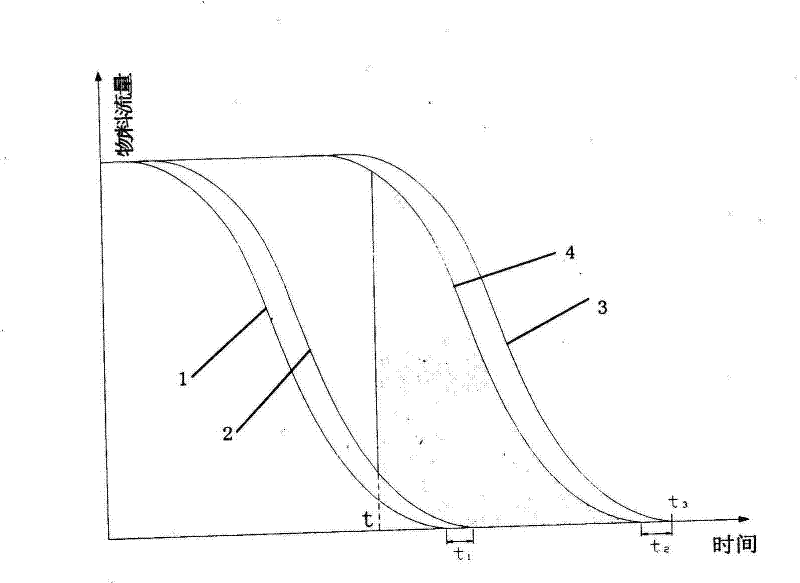

Experimental determining method of retention in tobacco material roller in processing flow

ActiveCN101975597ADetermination method is simpleOperation without downtimeMass flow measurement devicesAgricultural engineeringData acquisition

The invention discloses an experimental determining method of the retention in a tobacco material roller in the processing flow, comprising the following steps of: continuously determining the real-time mass flow of materials flowing through the front part and the rear part of the roller by using electronic belt scales which are respectively arranged at the front end and the rear end of roller equipment; acquiring and recording the mass flow data determined by the electronic belt scales by a data acquisition system; continuously acquiring the mass flow information of the materials at the front end and the rear end of the roller at the material head or tail stage; meanwhile, determining the delay time that the materials are transmitted to a roller inlet from the preposed electronic belt scale and transmitted to the post-positioned electronic belt scale from a roller outlet; acquiring the mass flow information of the materials at the roller outlet according to the mass flow information of the materials at the front end and the rear end of the roller and corresponding delay time; and calculating the retention of the materials in the roller at certain moment by the data acquisition system according to the flow of the materials at the inlet and the outlet of the roller at different moments.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

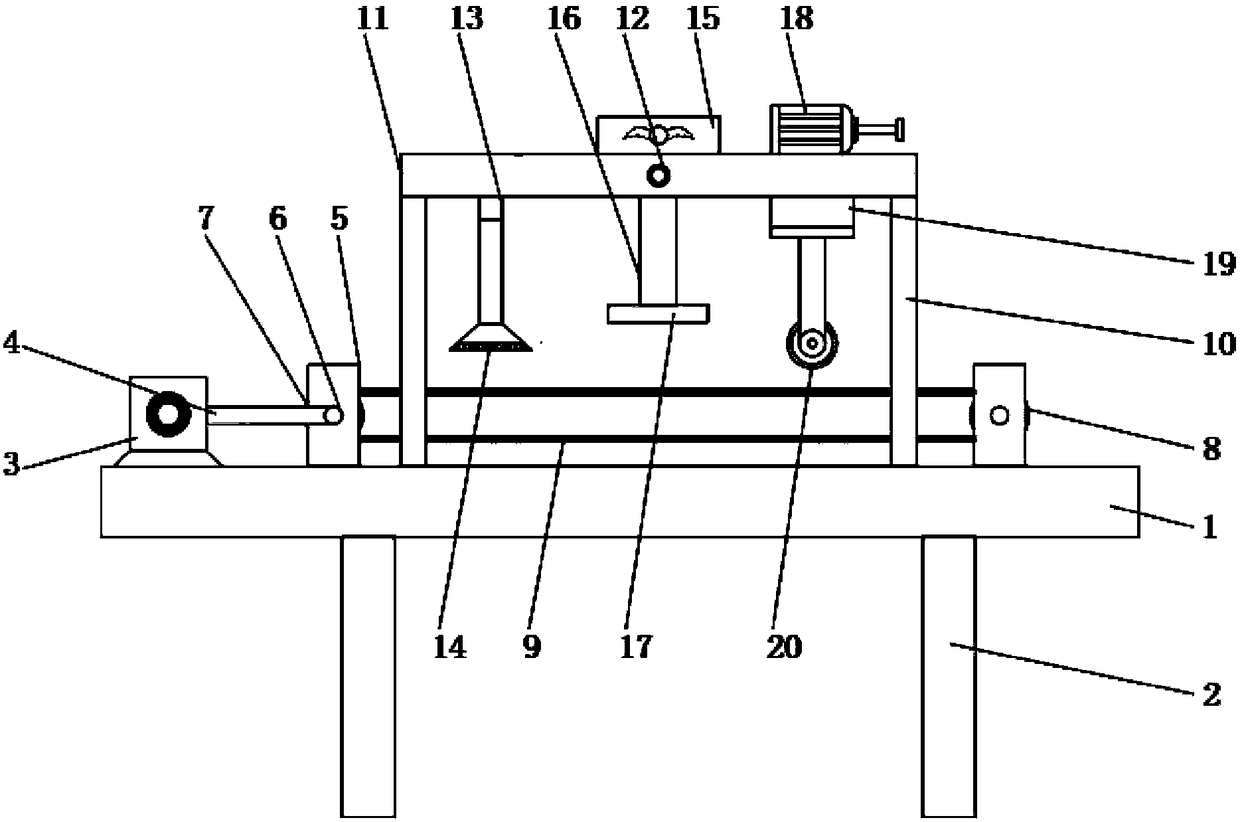

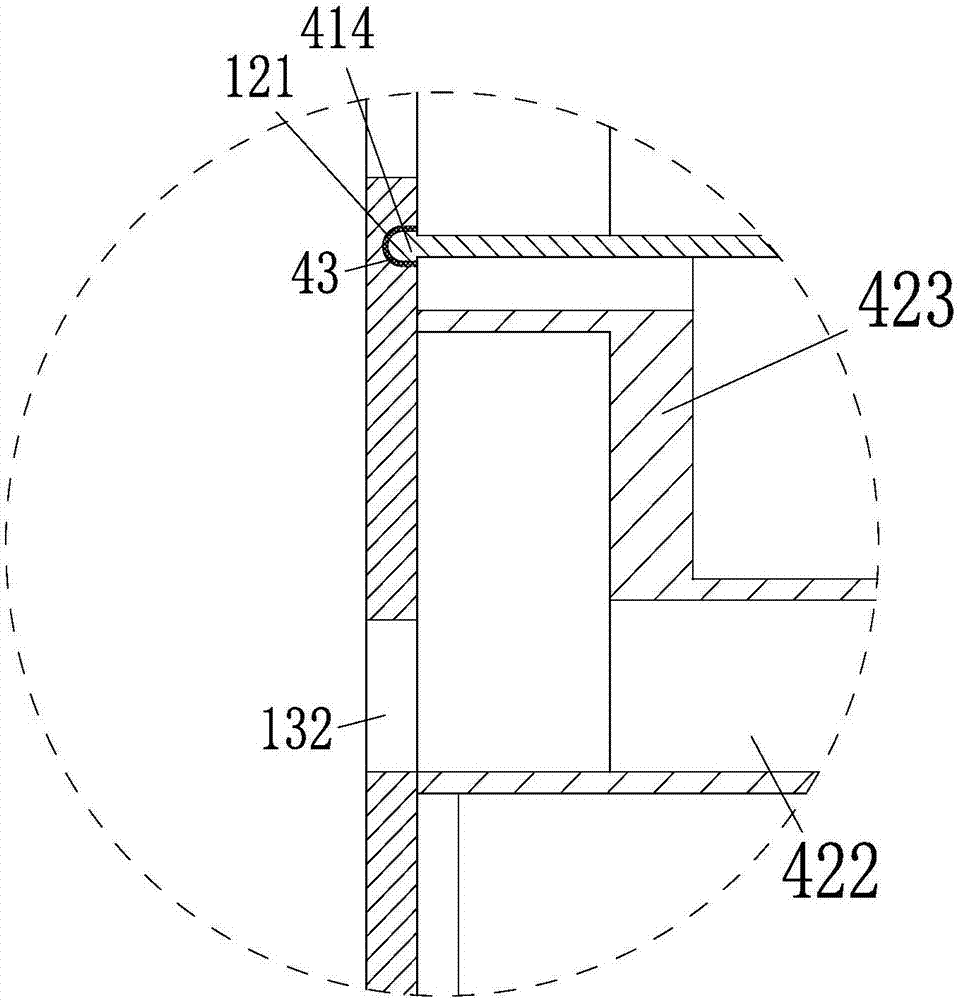

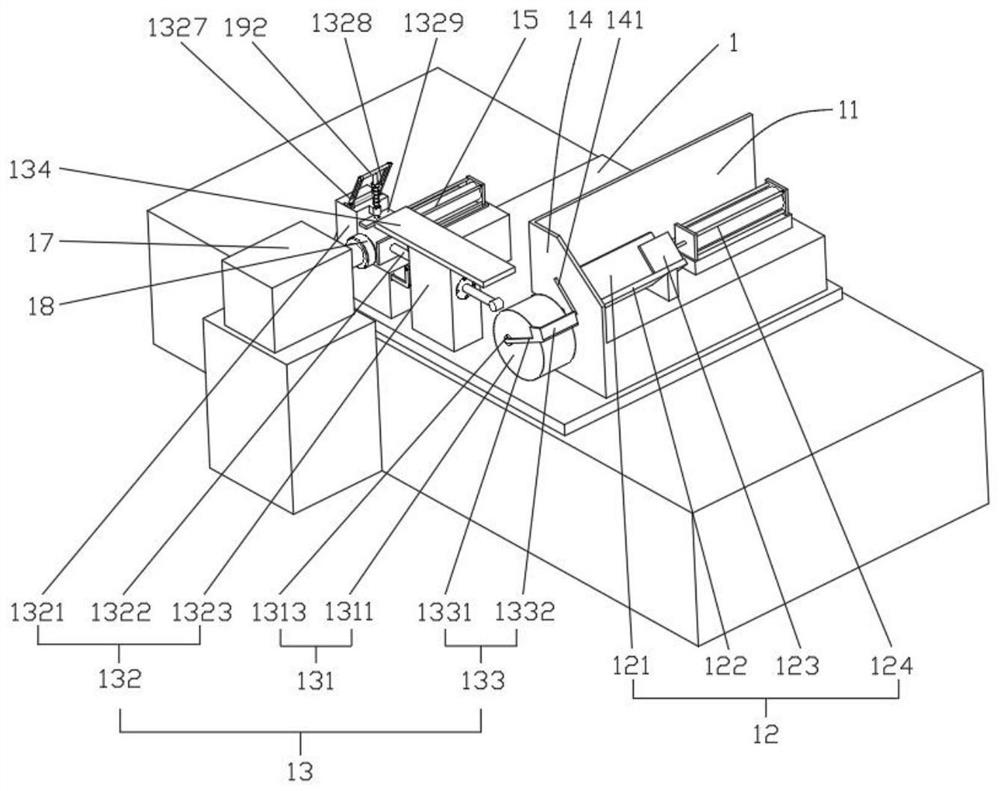

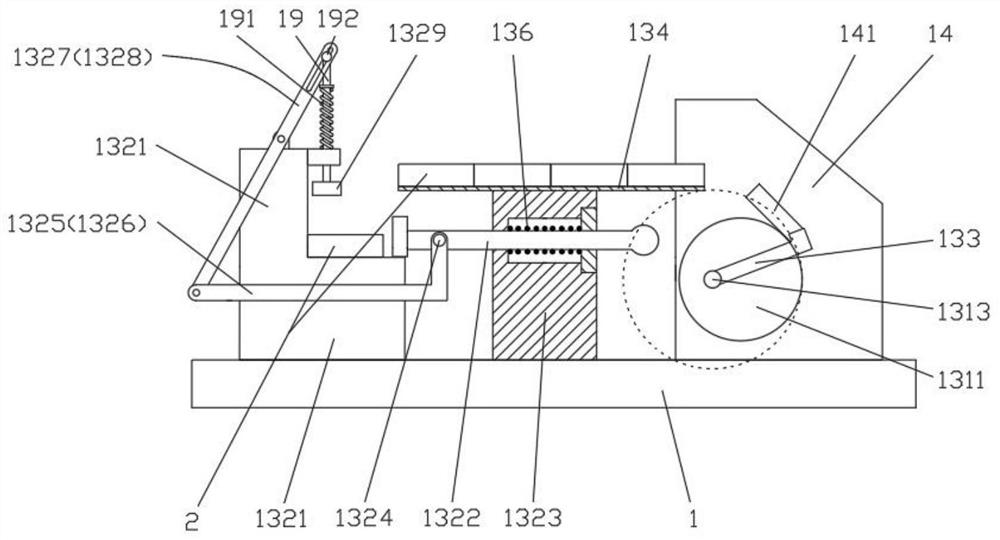

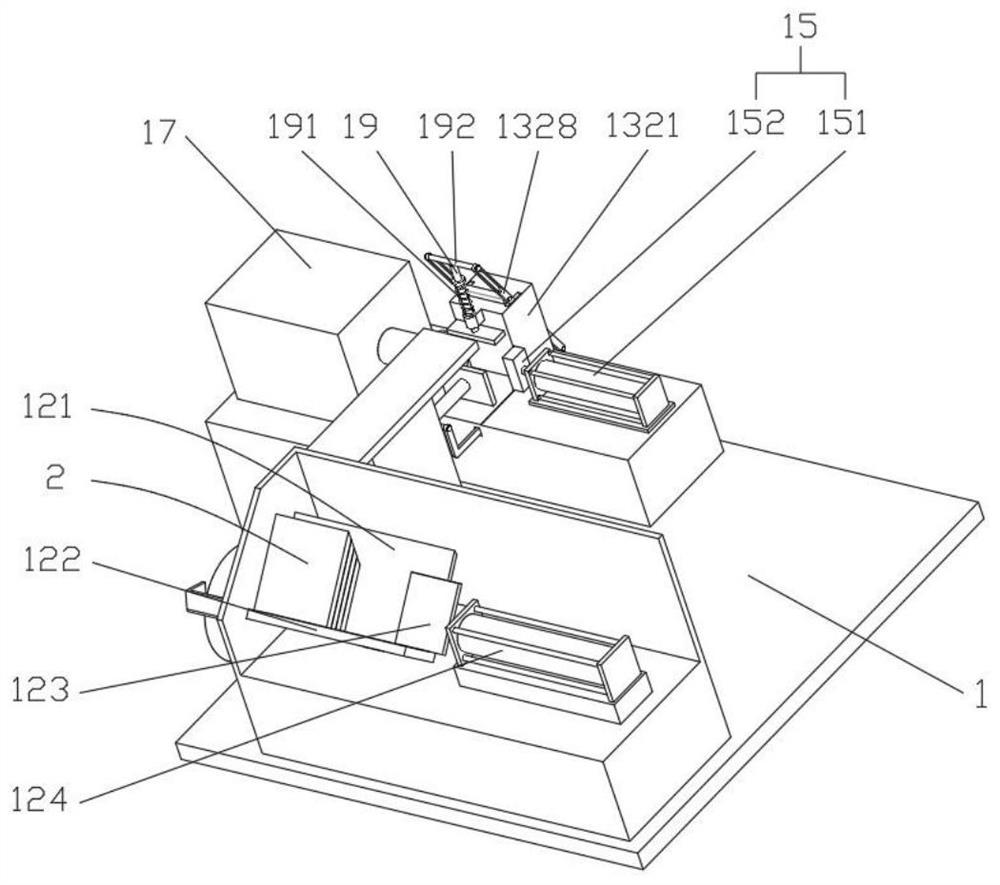

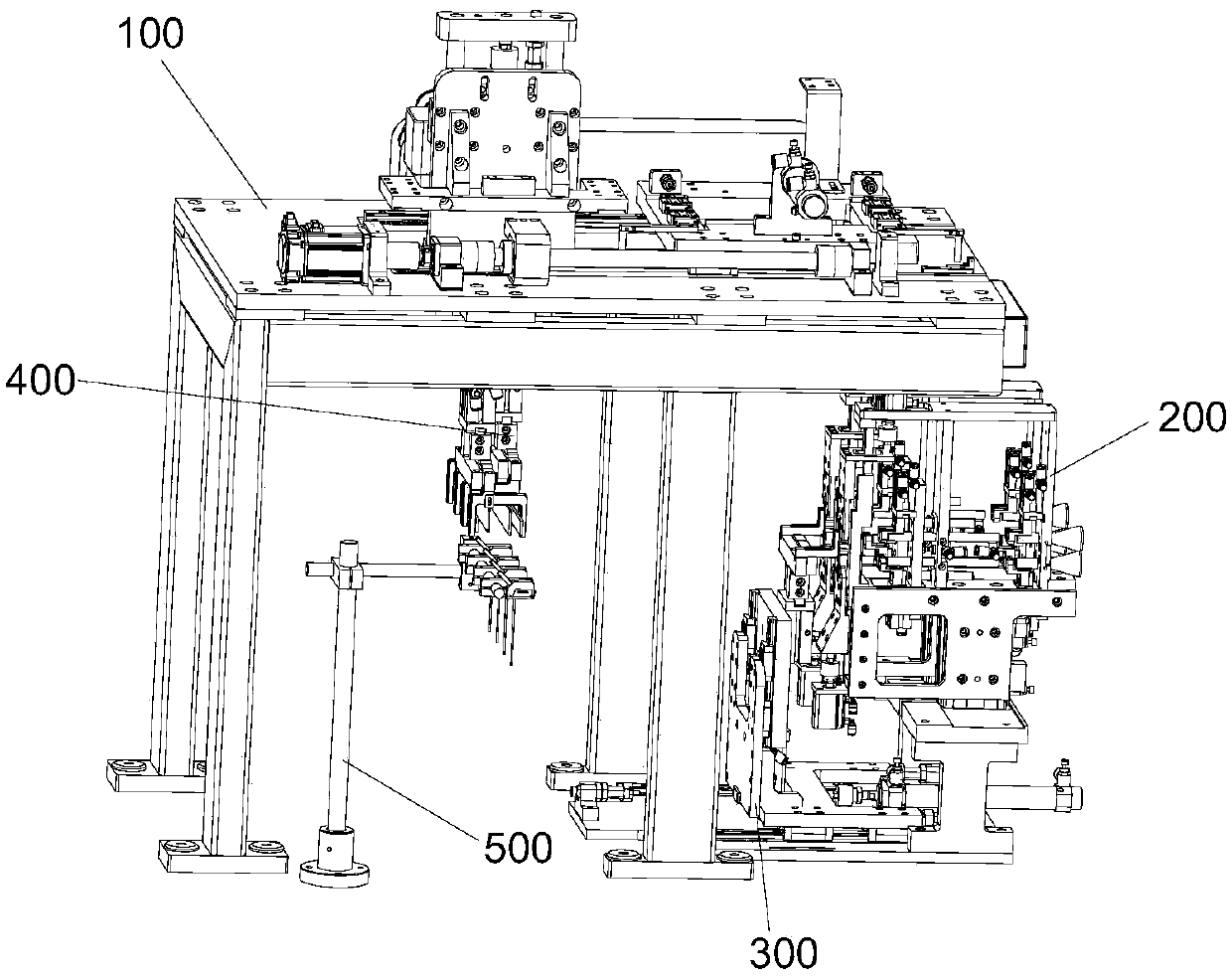

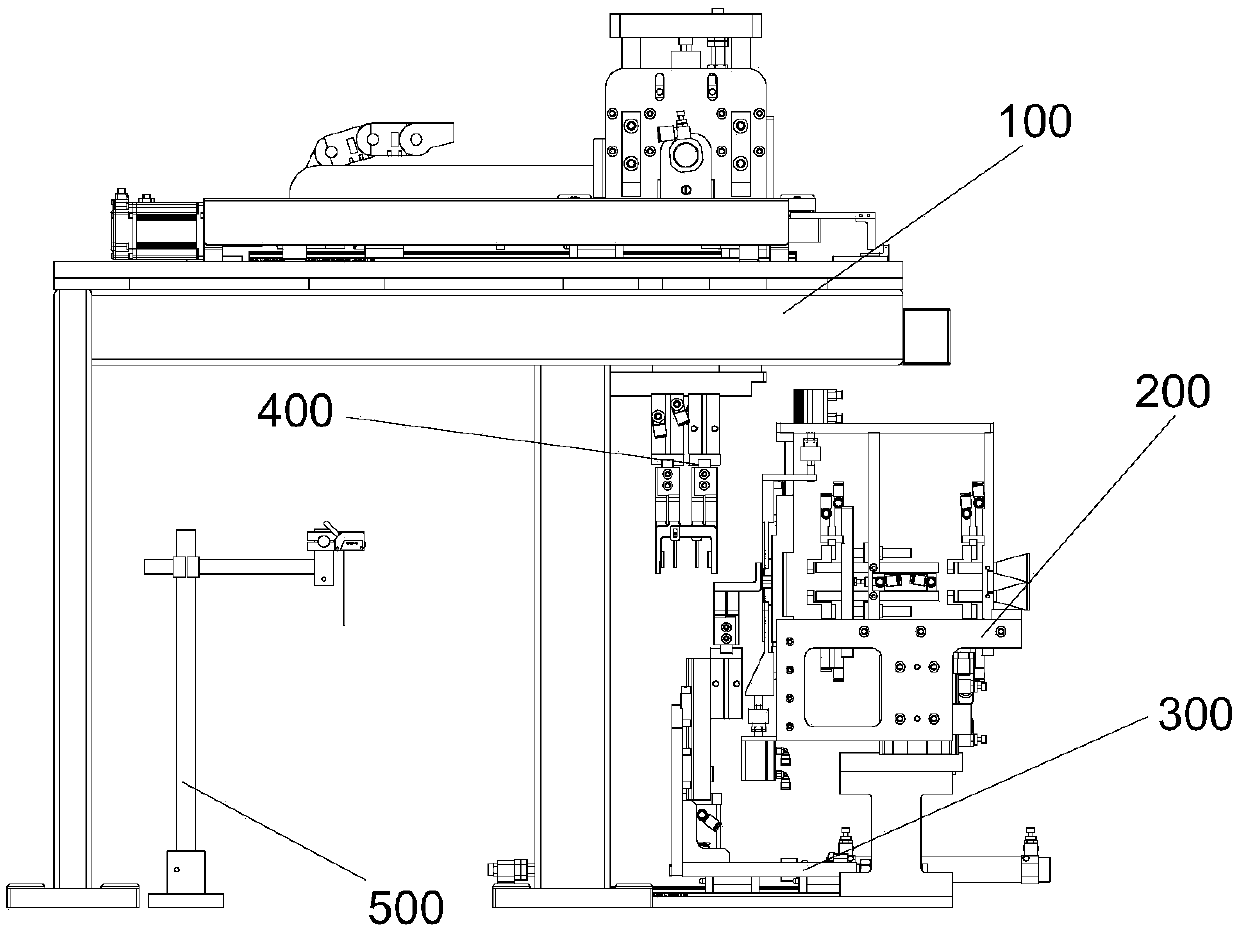

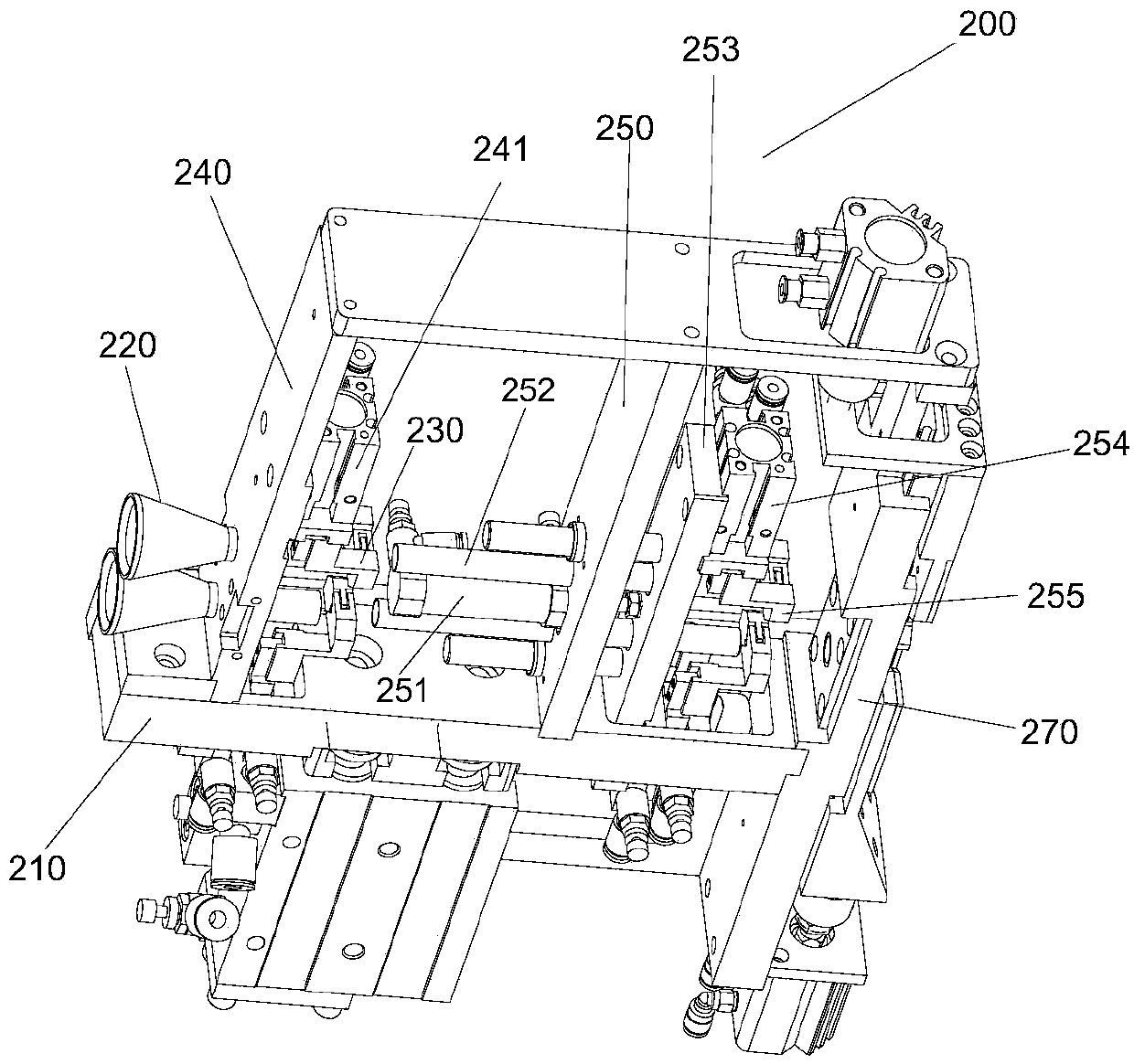

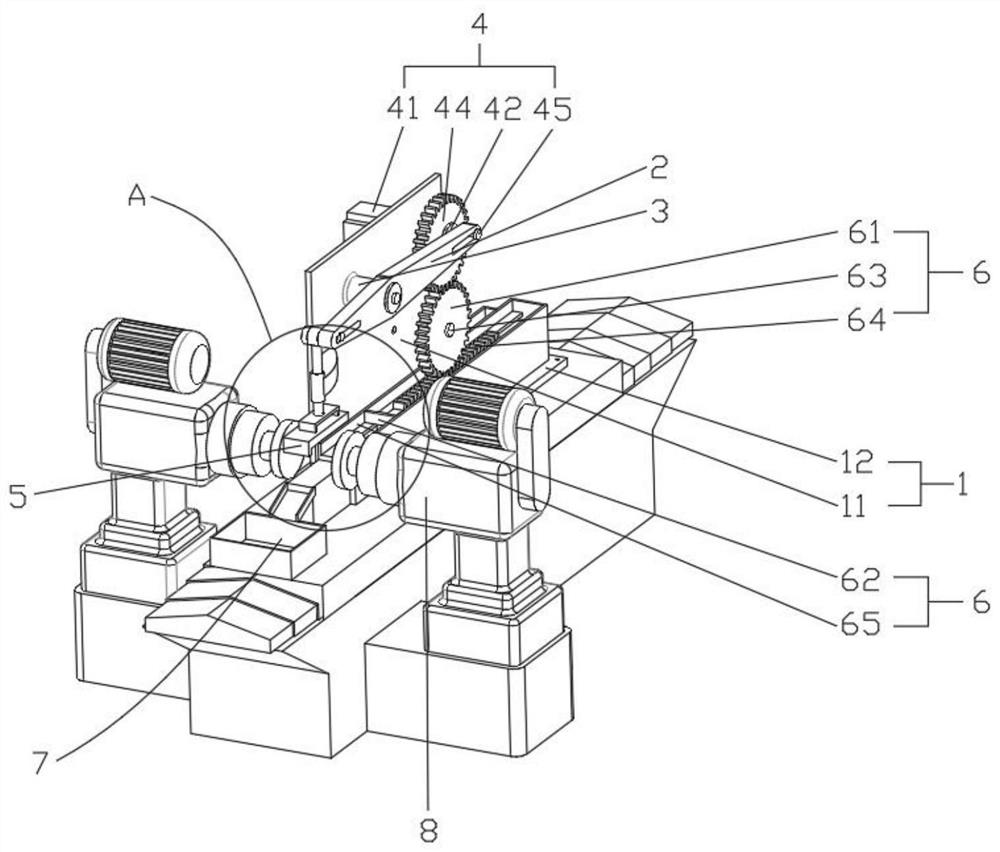

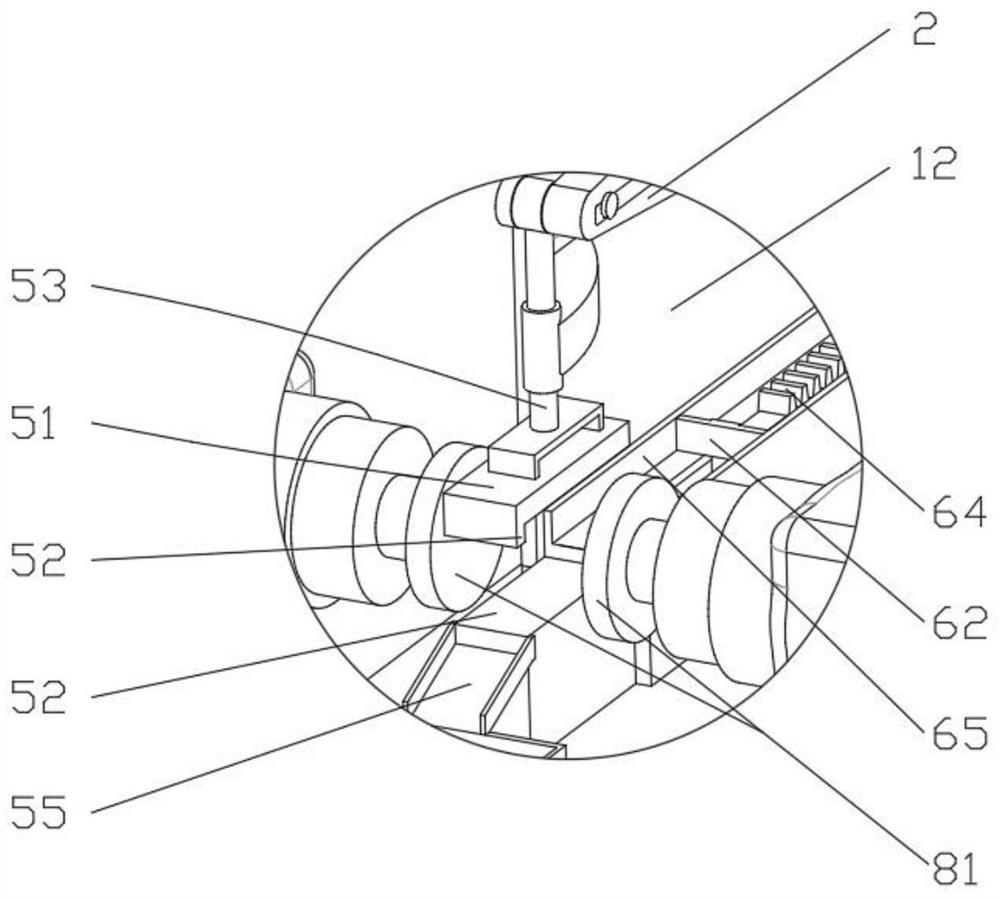

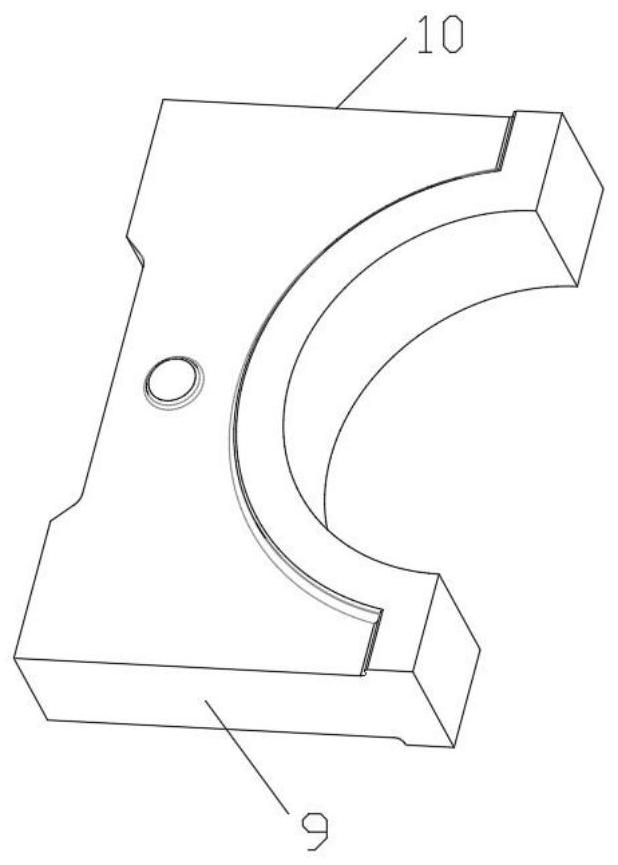

Automatic feeding device for end face machining

ActiveCN112720032AHigh degree of automationImprove processing efficiencyPositioning apparatusMetal working apparatusEngineeringPower equipment

The invention relates to the technical field of part machining, and discloses an automatic feeding device for end face machining. The automatic feeding device for end face machining comprises a pushing device, an automatic positioning device and a discharging device, wherein workpieces to be machined are continuously conveyed to the automatic positioning device through the pushing device so as to be positioned and clamped, and discharging is conducted through the discharging device, so that the continuous and automatic end face machining procedure is achieved, the automation degree is high, and the working efficiency is high; in addition, a conveying mechanism in the automatic positioning device drives a conveying wheel to do eccentric rotating motion through an eccentric shaft, so that clamping of the workpieces is achieved; in the workpiece conveying motion process of the conveying wheel, on one hand, the workpiece conveying path is increased, and the diameter of the conveying wheel needed for conveying the workpieces with the same size is reduced, so that the equipment size is reduced, and the equipment cost is reduced; on the other hand, the conveying wheel can drive a positioning mechanism to position the workpieces in the eccentric movement process, so that the synchronism between the positioning mechanism and the conveying mechanism is guaranteed; and the positioning mechanism does not need extra power, so that the equipment cost is low.

Owner:襄阳鼎超机械制造有限公司

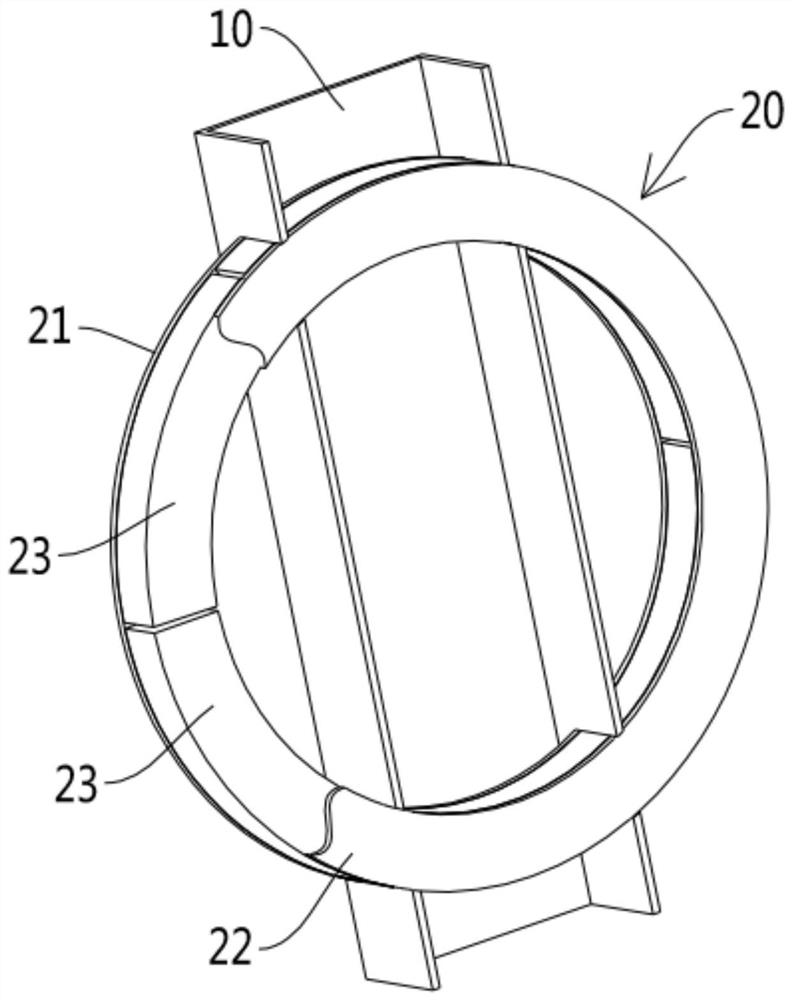

Power plant flue ash removal device

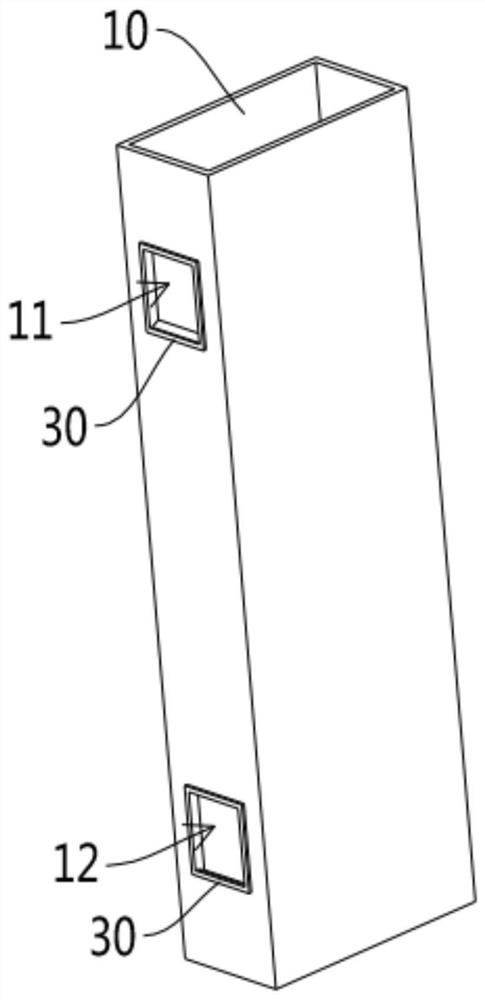

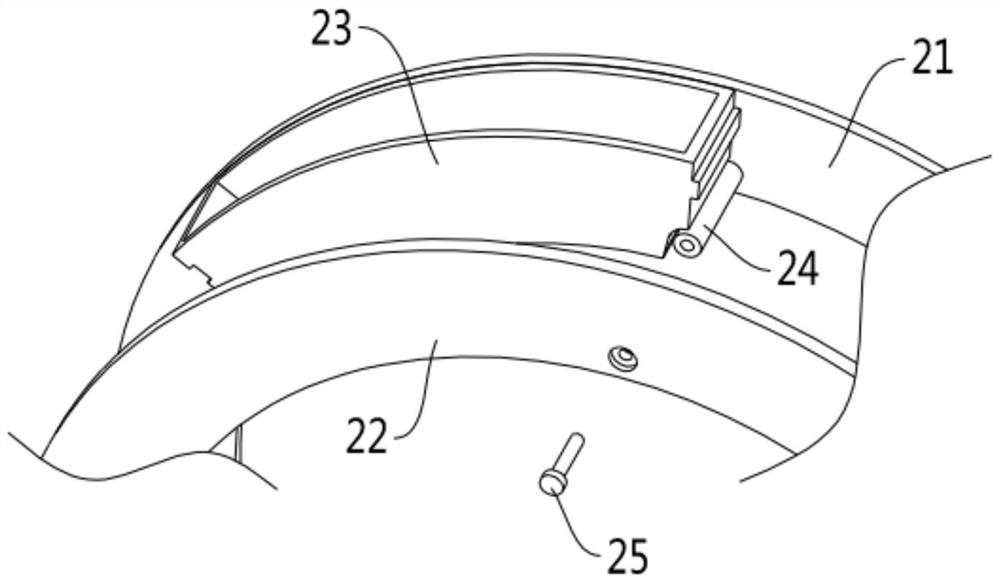

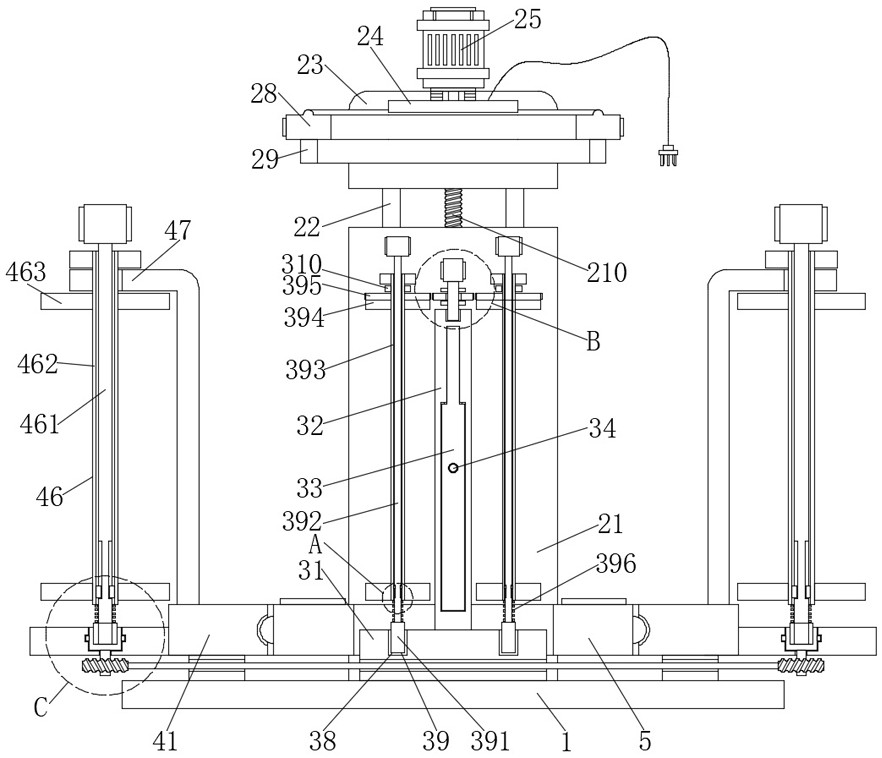

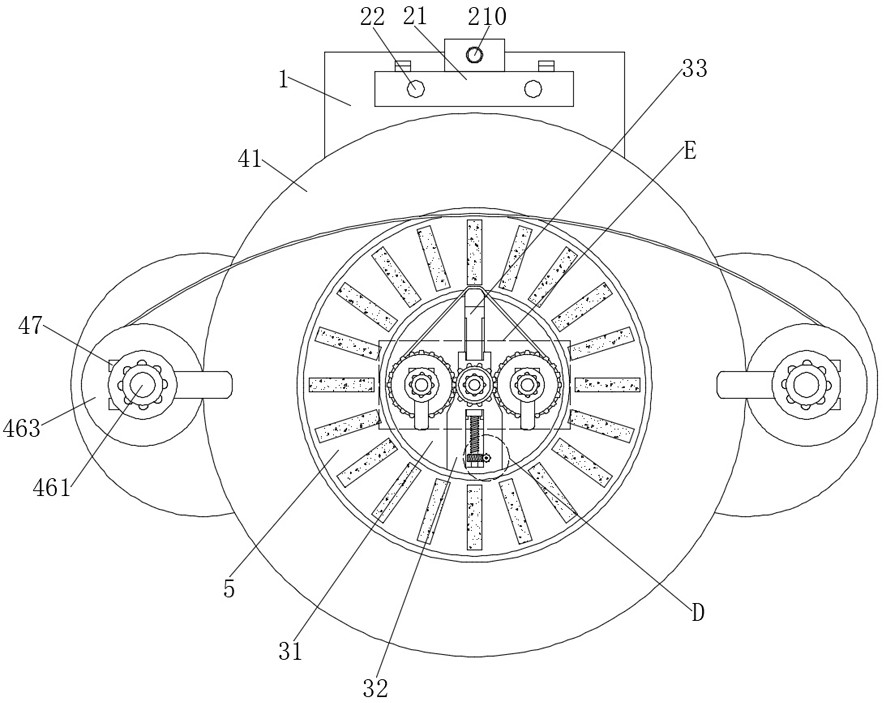

PendingCN113188139AOperation without downtimeEasy to useDispersed particle filtrationSolid removalProcess engineeringMechanical engineering

The invention discloses a power plant flue ash removal device which comprises a flue and an ash removal assembly, the ash removal assembly is in a circular ring shape, the flue is provided with a first adjusting channel and a second adjusting channel, the first adjusting channel and the second adjusting channel are used for allowing the ash removal assembly to penetrate through and do circumferential rotation in the flue, and the ash removal assembly comprises a first circular ring piece and a second circular ring piece. A plurality of filtering units which are arranged in the circumferential direction of the ash removal assembly are arranged between the first circular ring piece and the second circular ring piece. Each filtering unit comprises a shell, a filter element is filled in the shell, and a filter opening for enabling the filter element to be in contact with smoke dust in the flue is formed in the shell. The filter element is a raised flannelette or a needled felt. The power plant flue ash removal device has the characteristics of ingenious structure and convenience in use, and is complete in overall function and high in practicability.

Owner:JIAXING NEW JIES THERMAL POWER

A mechanism for polishing the inner and outer walls of a press-fit gasket of a fastener

ActiveCN111098219BReduce work stepsImprove work efficiencyPolishing machinesGrinding drivesGear wheelElectric machinery

Owner:NINGBO JINDING FASTENING PIECE

Experimental determining method of retention in tobacco material roller in processing flow

ActiveCN101975597BDetermination method is simpleOperation without downtimeMass flow measurement devicesData acquisitionEngineering

The invention discloses an experimental determining method of the retention in a tobacco material roller in the processing flow, comprising the following steps of: continuously determining the real-time mass flow of materials flowing through the front part and the rear part of the roller by using electronic belt scales which are respectively arranged at the front end and the rear end of roller equipment; acquiring and recording the mass flow data determined by the electronic belt scales by a data acquisition system; continuously acquiring the mass flow information of the materials at the front end and the rear end of the roller at the material head or tail stage; meanwhile, determining the delay time that the materials are transmitted to a roller inlet from the preposed electronic belt scale and transmitted to the post-positioned electronic belt scale from a roller outlet; acquiring the mass flow information of the materials at the roller outlet according to the mass flow information of the materials at the front end and the rear end of the roller and corresponding delay time; and calculating the retention of the materials in the roller at certain moment by the data acquisition system according to the flow of the materials at the inlet and the outlet of the roller at different moments.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

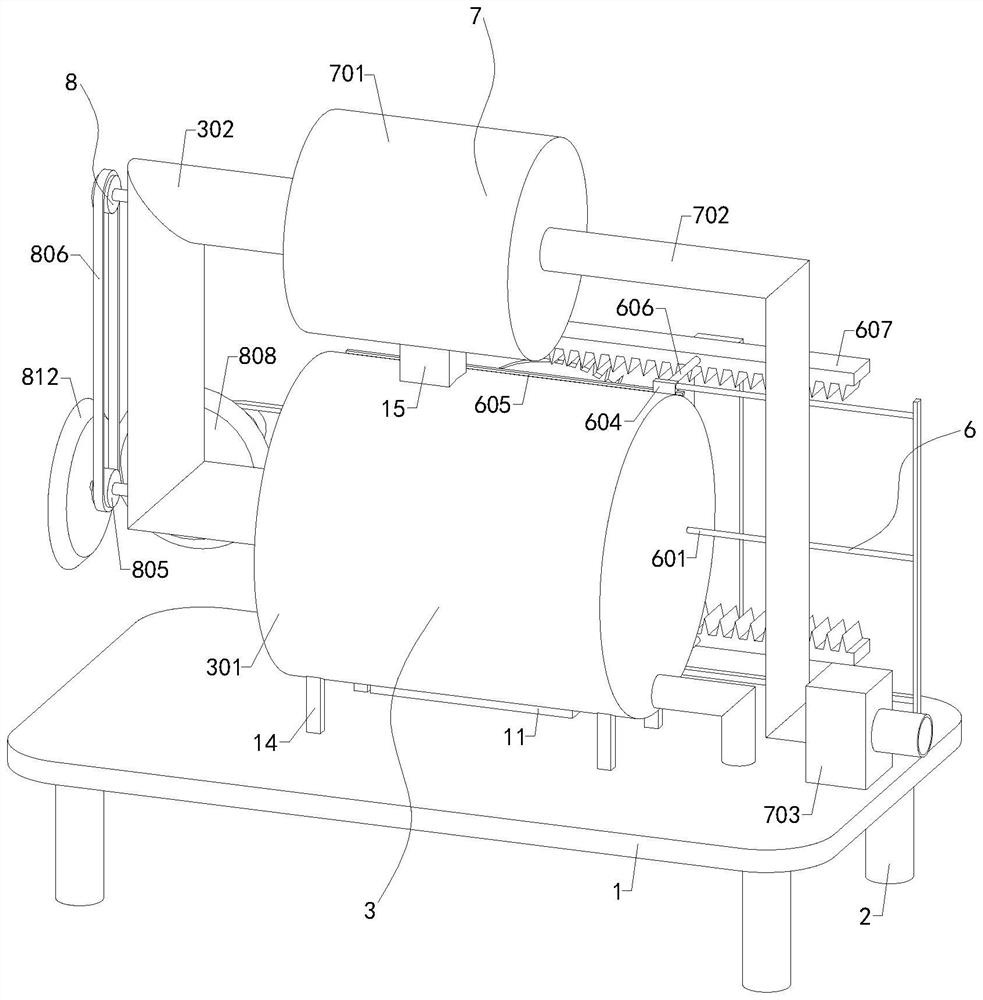

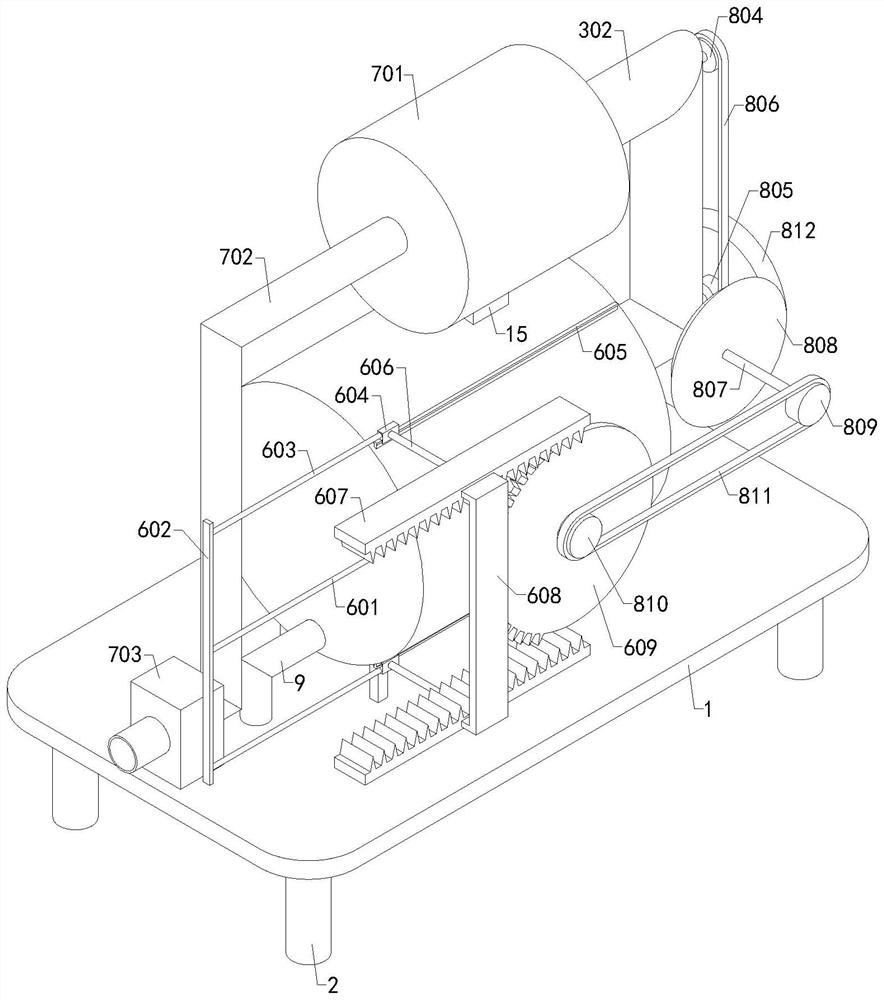

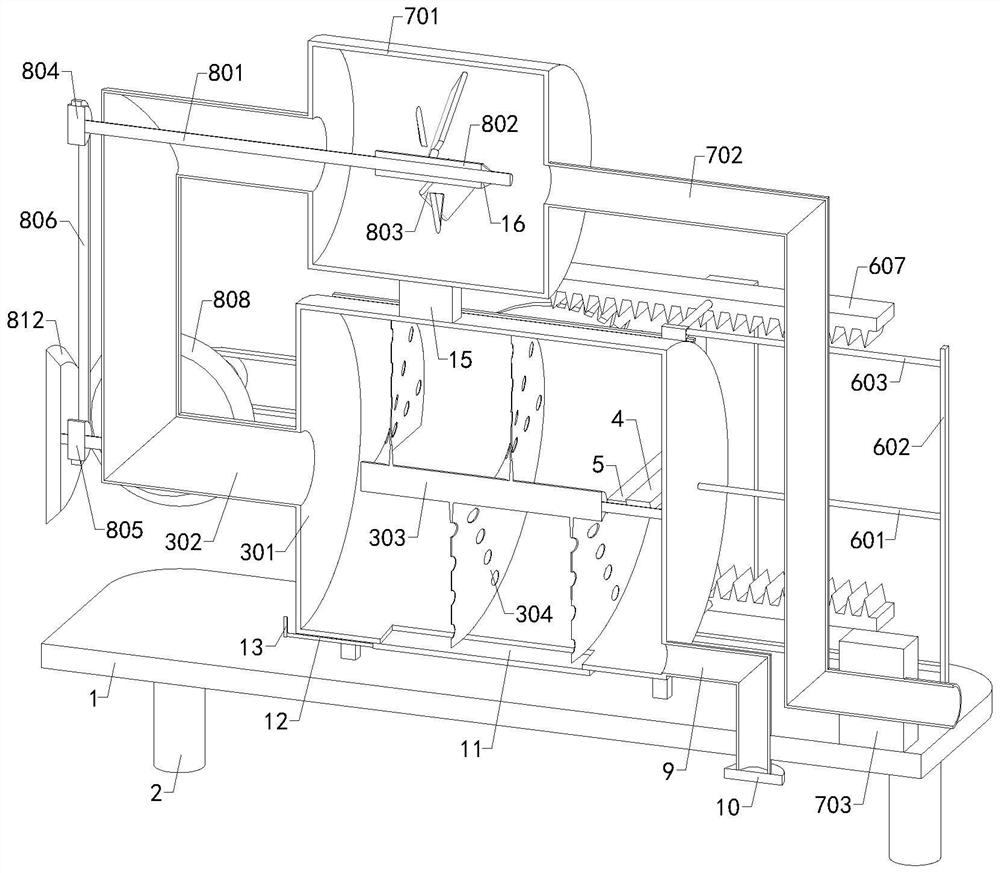

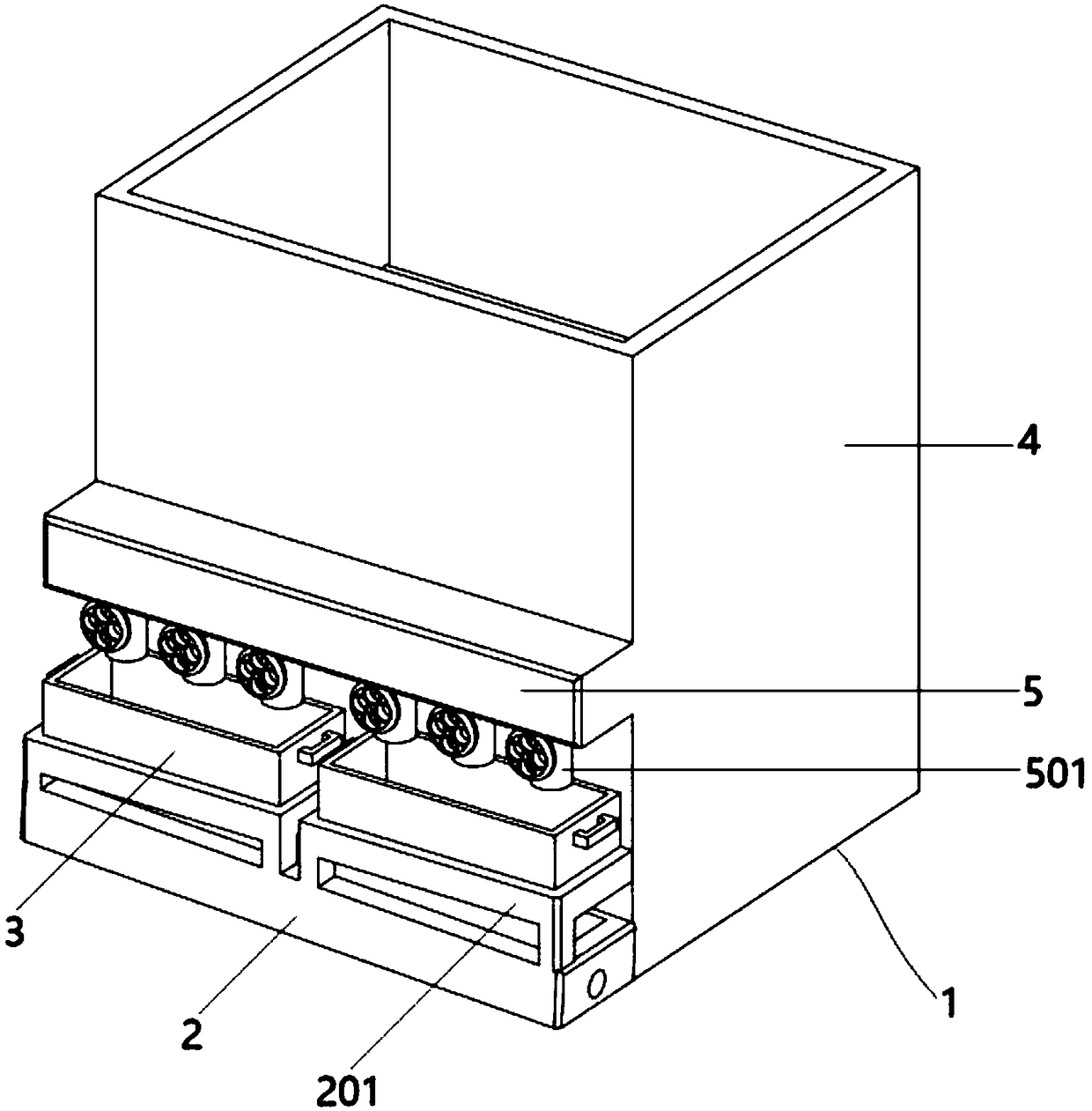

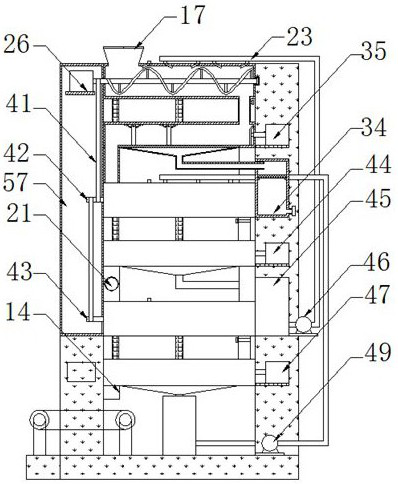

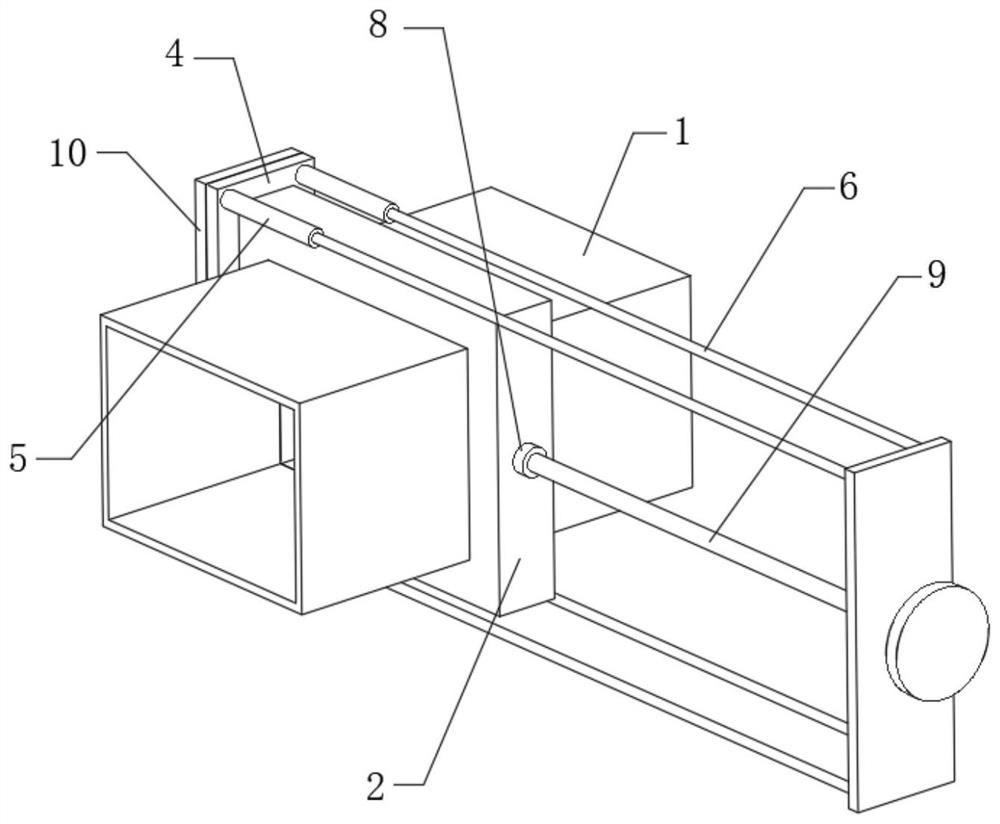

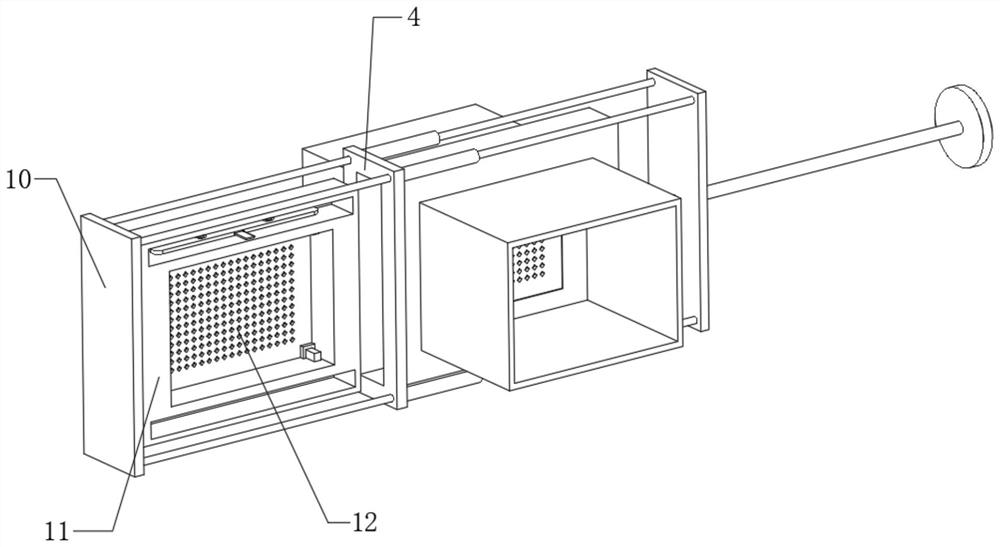

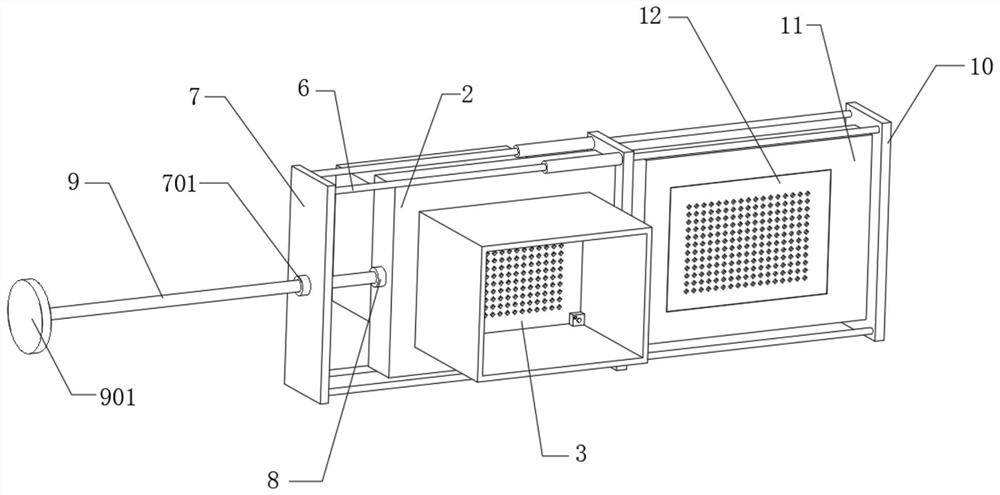

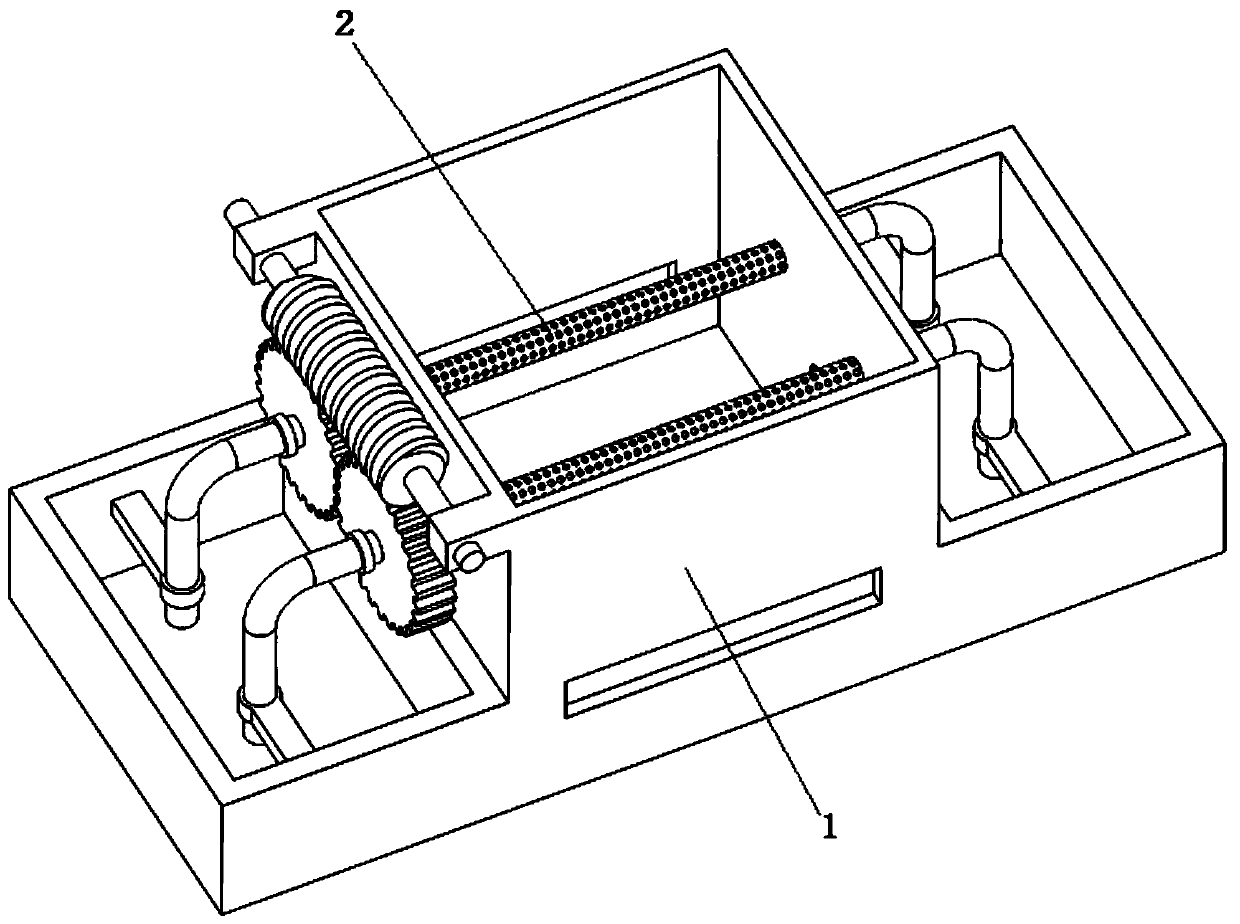

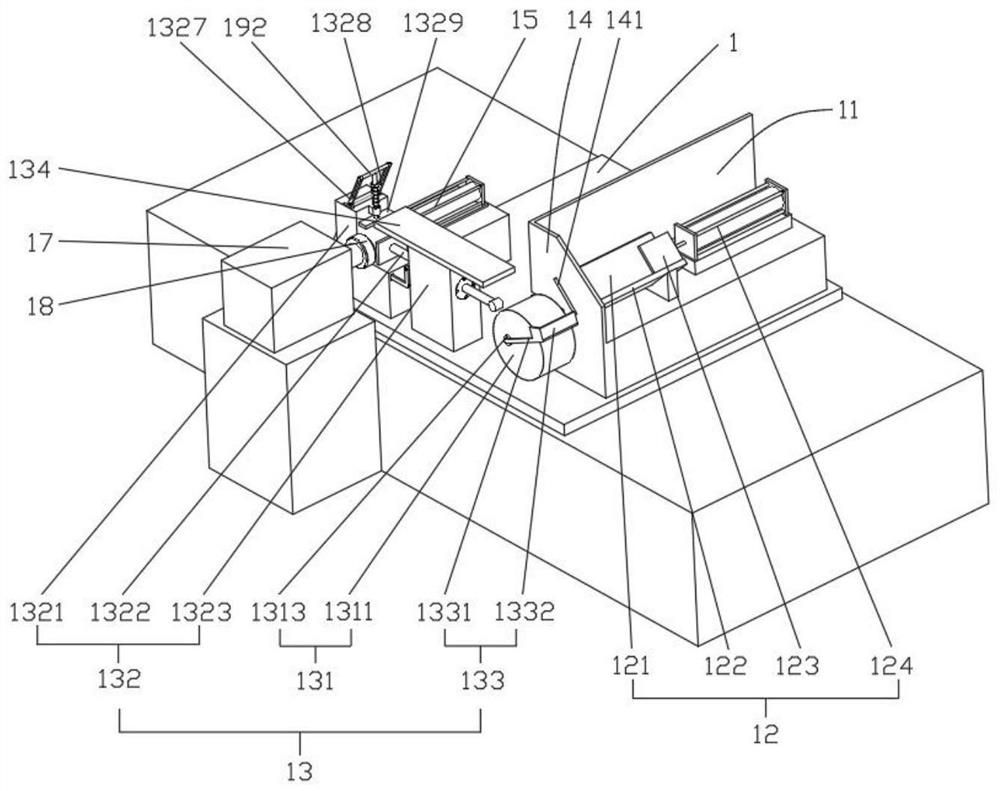

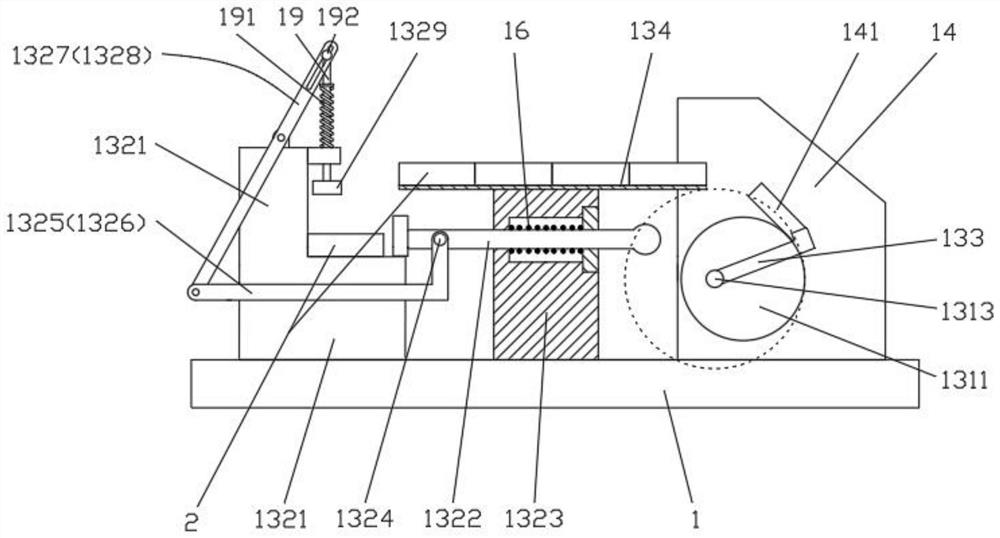

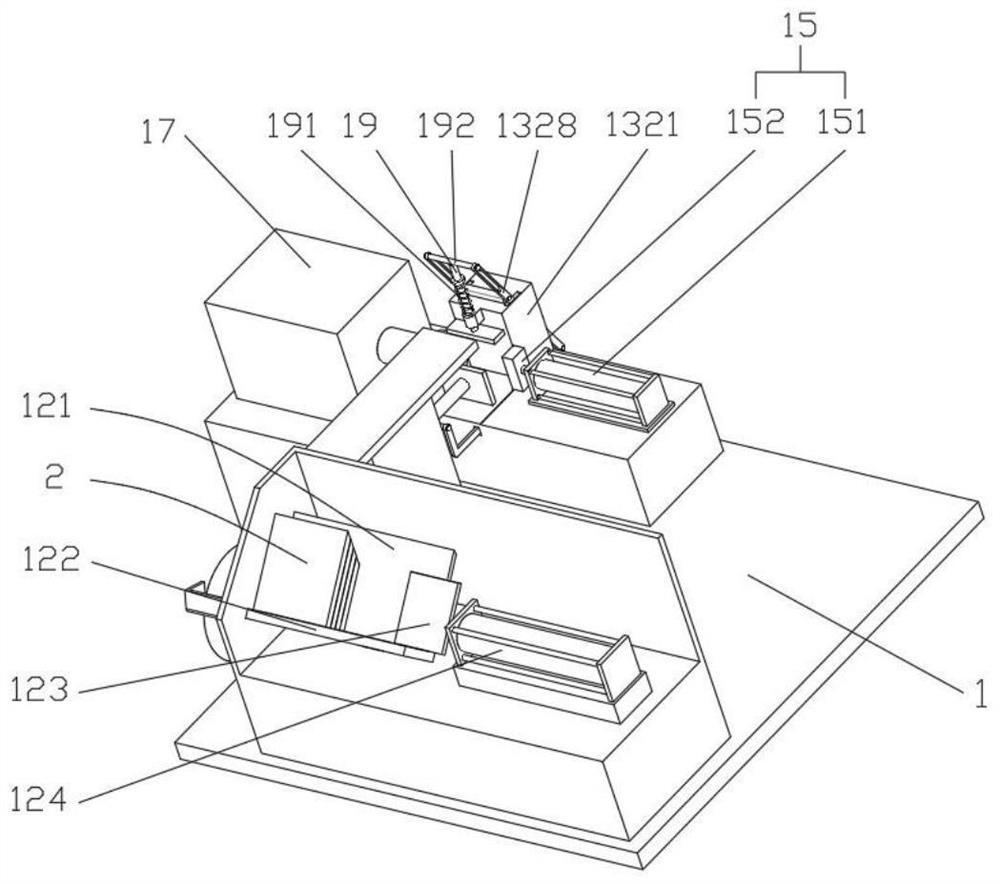

A Tobacco Online Countercurrent Spiral Extraction Device

ActiveCN110025975BReduce consumptionImprove extraction efficiencyTobacco treatmentCounter-current extractionEngineeringProcess engineering

The invention discloses an online countercurrent spiral extraction device for tobacco, which comprises a base, support columns are fixed on both sides of the top of the base, a first-stage extraction device is fixed on the top between the two support columns, and a primary extraction device is directly below the first-stage extraction device. There is a first-stage squeezing device, and directly below the first-stage squeezing device is provided with a second-stage extraction device, a second-stage squeezing device, a third-stage extraction device, and a third-stage squeezing device. The first-stage extraction device includes the first smoke soaking box, One side of the bottom end of the first soaking box communicates with the top side of the first squeezing box through the first feed pipe, and one end of the first soaking box is provided with a motor, which is protected by the fixing seat and the side of the first squeezing box. The cover is fixedly connected, and the present invention is an online countercurrent spiral extraction device for tobacco, which extracts the tobacco sequentially through three stages, reduces the consumption of water source, has high extraction efficiency, does not need to stop operation, improves work efficiency, is more environmentally friendly, has strong overall practicability, and is easy to extract. promote.

Owner:YUNNAN AGRICULTURAL UNIVERSITY +1

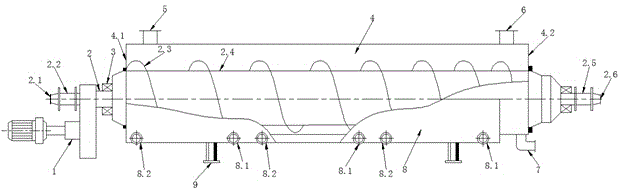

Horizontal screw structure pyrolysis furnace for recycling waste tire resources

InactiveCN104357077BShorten the production cycleIncrease heat transfer areaPigmenting treatmentPlastic recyclingSpiral bladeRetention time

The invention discloses a horizontal type screw rod structure cracking furnace for waste tire resource recycling. The horizontal type screw rod structure cracking furnace comprises a sealed furnace body, wherein a tire block inlet tube and a cracking gas outlet tube are respectively arranged on the left side of the upper part and the right side of the upper part of the furnace body; the furnace body is internally provided with a rotor; two ends of the rotor are respectively supported in a left bearing support and a right bearing support; the rotor is driven to rotate through a transmission system at the left end of the rotor; a heating jacket is arranged at the lower part of the outer side of the furnace body; a cracking product outlet tube is arranged at the lower part of the right end of the furnace body; the whole device is mounted on a saddle support. A heat source is provided by virtue of a hollow shaft and the jacket together, so that a great heat conduction area is achieved; separated cracking products can be used as the heat source; the high-temperature gas inside the hollow shaft and the jacket flows in a countercurrent manner, the jacket only wraps a lower cylinder and contacts a cracking reaction position, multi-stage serial connection is adopted, and baffle plates are arranged inside the jacket, so that the retention time of the high-temperature gas is prolonged; the screw pitches of spiral blades are spare in the front part and dense in the rear part, the cracking products are completely discharged outside the cylinder along with rotation of the spiral blades, and shutdown operation is not required.

Owner:ZHEJIANG UNIV

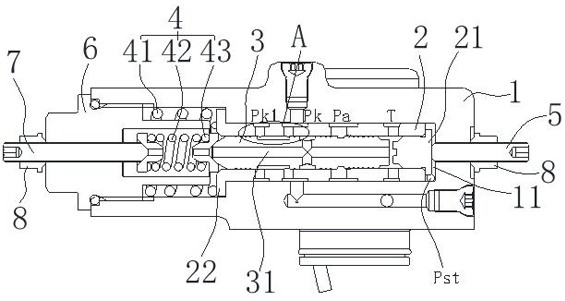

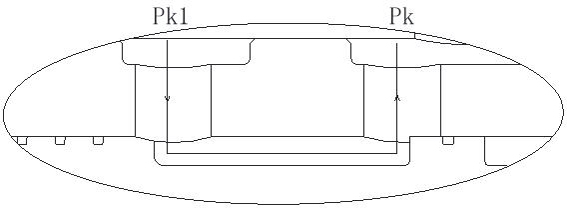

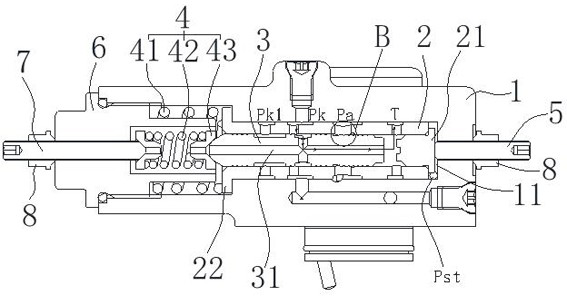

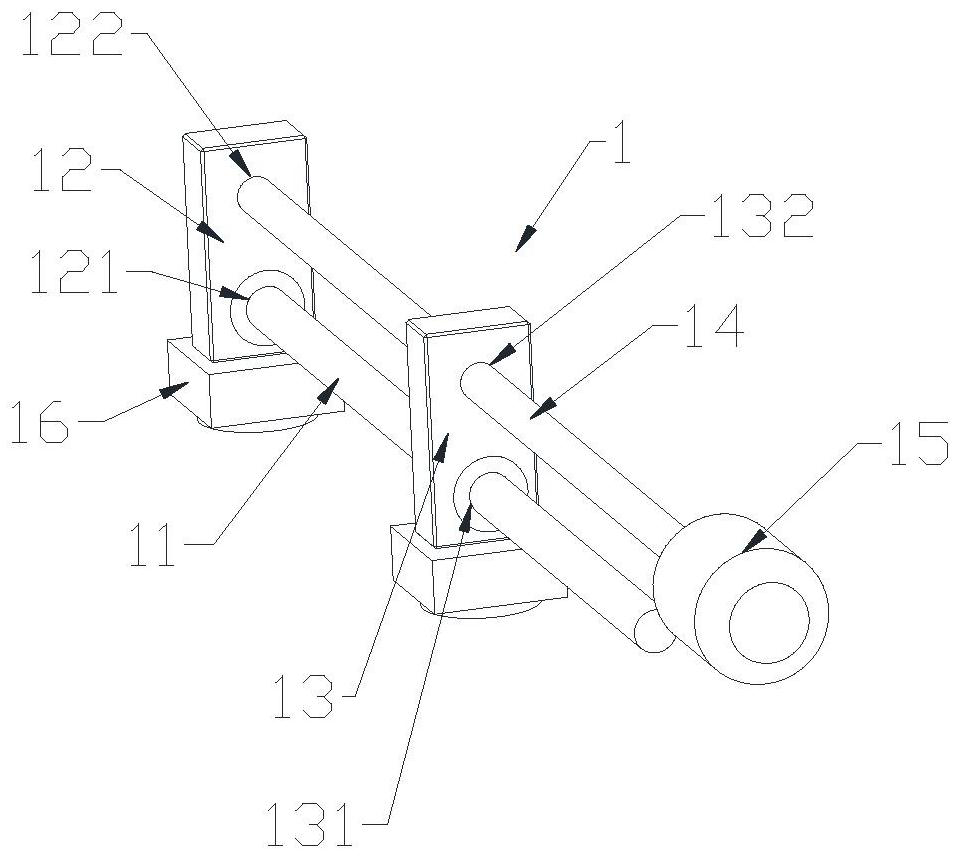

Pressure adaptation control mechanism and hydraulic motor

ActiveCN114704519ARealize adaptive adjustmentOperation without downtimeOperating means/releasing devices for valvesServomotor componentsHydraulic motorEngineering

The invention relates to the technical field of hydraulic motors, in particular to a pressure adaptation control mechanism and a hydraulic motor. Comprising a valve body in which a plurality of oil passages are formed; the valve sleeve is assembled in the valve body in a sliding mode, a plurality of oil ports are formed in the valve sleeve and correspondingly communicated with the oil channels, and pilot acting force is formed on the axial side of the valve sleeve; the valve element is assembled in the valve sleeve in a sliding mode, and the valve element controls connection and disconnection of the multiple oil ports in a sliding mode; the pressure control assembly is located on the other axial side of the valve sleeve and comprises a pressure adjusting elastic piece and a constant-pressure elastic piece which are arranged in a sleeved mode, the pressure adjusting elastic piece acts on the valve sleeve, the constant-pressure elastic piece acts on the valve element, the valve element slides under the action of pressure oil, and the constant-pressure elastic piece acts on the constant-pressure elastic piece. And the valve sleeve slides under the action of the pilot acting force. The technical problems that in the prior art, the pressure of a hydraulic system adjusted by a constant pressure valve cannot be changed in the operation process, and the use difficulty is increased are solved.

Owner:JIANGSU HENGLI HYDRAULIC TECH CO LTD

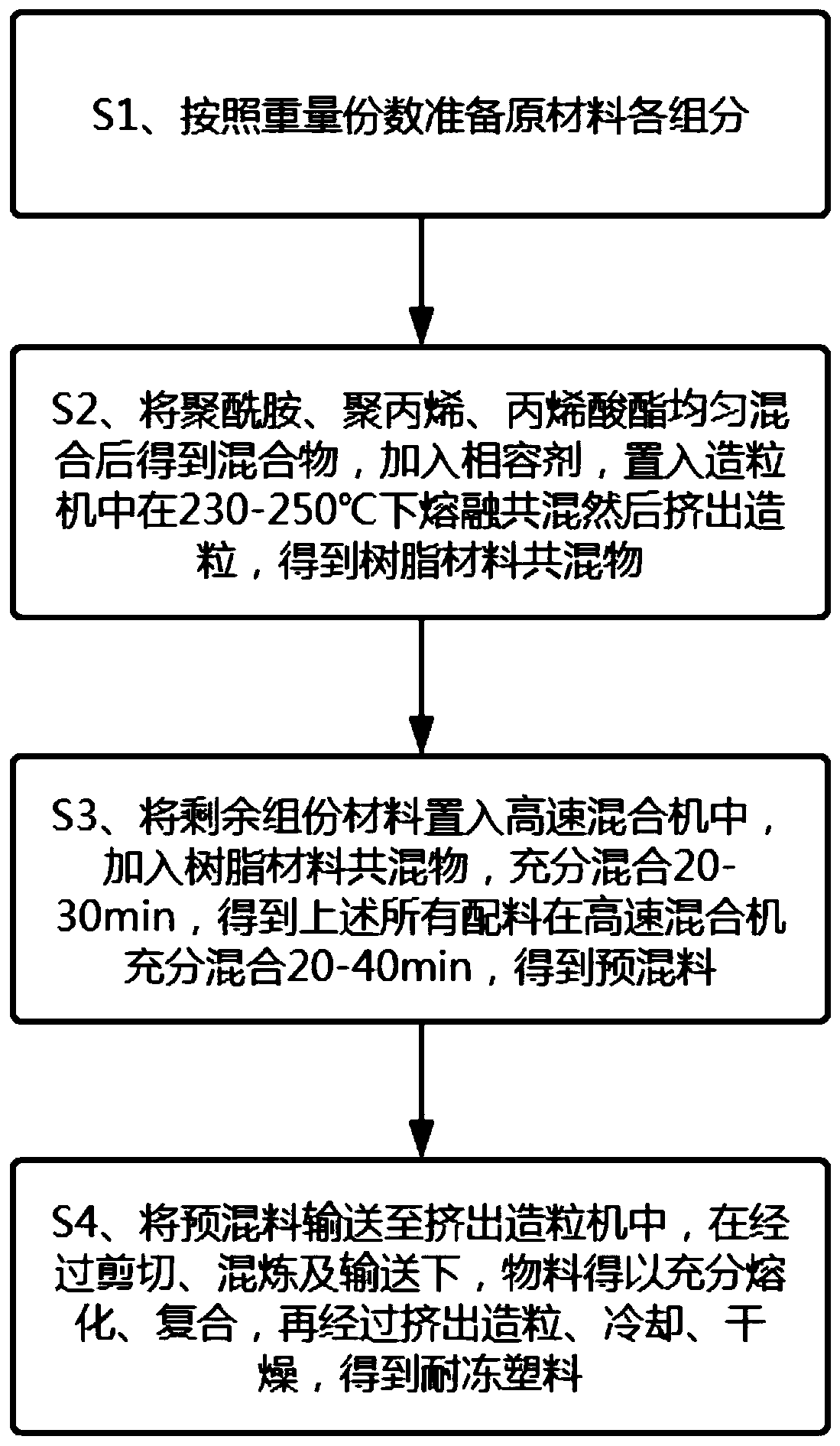

Freezing-resistant plastic used in extremely cold environment

InactiveCN111057366AImproved shock resistanceImprove low temperature resistanceCoatingsPolymer sciencePolystyrene

The invention discloses a freezing-resistant plastic used in an extremely cold environment, which belongs to the technical field of plastic products, and the freezing-resistant plastic comprises polyamide, polypropylene, polystyrene resin, diatomite, ultrafine calcium carbonate, silicon nitride, a composite flame retardant, a cold-resistant plasticizer, a weather-resistant agent, an anti-crackingagent, an antioxidant, an antibacterial agent and other components, and the preparation method comprises the following steps: preparing the raw material components according to parts by weight; preparing a resin material blend; fully mixing to obtain a premix; and conveying the premix into an extrusion granulator, and carrying out extrusion granulation, cooling and drying to obtain the freezing-resistant plastic. According to the freezing-resistant plastic disclosed by the invention, the polyamide, the polypropylene and the acrylate are used as main raw materials, the polyamide and the polypropylene have good low-temperature resistance, a compatilizer with specific components is added, so that the defect of poor solvent resistance of resin is overcome, and the low-temperature impact resistance of the modified plastic is greatly improved by introducing the polystyrene resin.

Owner:黄金平

A kind of online cleaning method of titanium plate heat exchanger

ActiveCN108050882BRealize online cleaningOperation without downtimeFlush cleaningHeat transfer efficiencyTitanium plate

The invention discloses an online cleaning method for a titanium plate-type heat exchanger and relates to the technical field of the cleaning of plate-type heat exchangers. The online cleaning methodcomprises the four steps of primary washing, pickling, mixed pickling and secondary washing in sequence; through the primary washing, pickling and mixed pickling steps, water, an acid solution and a mixed acid solution can correspondingly pass through the interior of the titanium plate-type heat exchanger; through the secondary washing step, water can pass through the interior of the titanium plate-type heat exchanger again; in the acid solution, the mass fraction of nitric acid is 10-12% and the mass fraction of a corrosion inhibitor LAN-826 is 0.25%; and in the mixed acid solution, the massfraction of nitric acid is 6-8%, the mass fraction of hydrochloric acid is 2.5-3% and the mass fraction of the corrosion inhibitor LAN-826 is 0.25%. The online cleaning method can be implemented in anonline manner and the influence on production can be avoided; the online cleaning method is simple and the corrosion to the titanium plate-type heat exchanger is relatively low; and dirt can be cleaned up, the heat transfer efficiency can be improved, and the relatively high economic value can be achieved.

Owner:PANZHIHUA STEEL ENTERPRISES XINYU CHEM

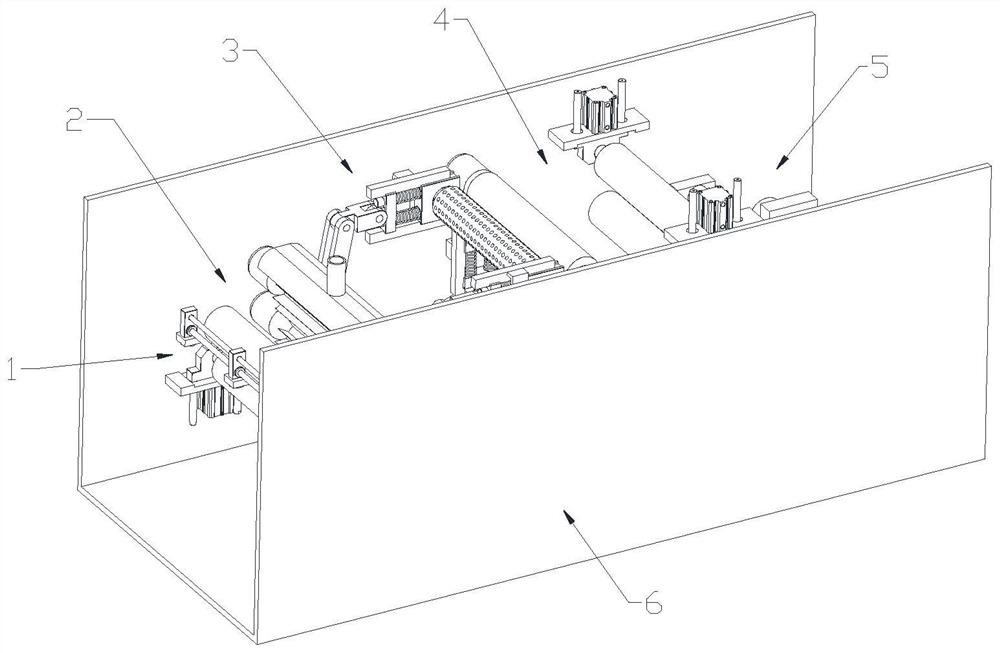

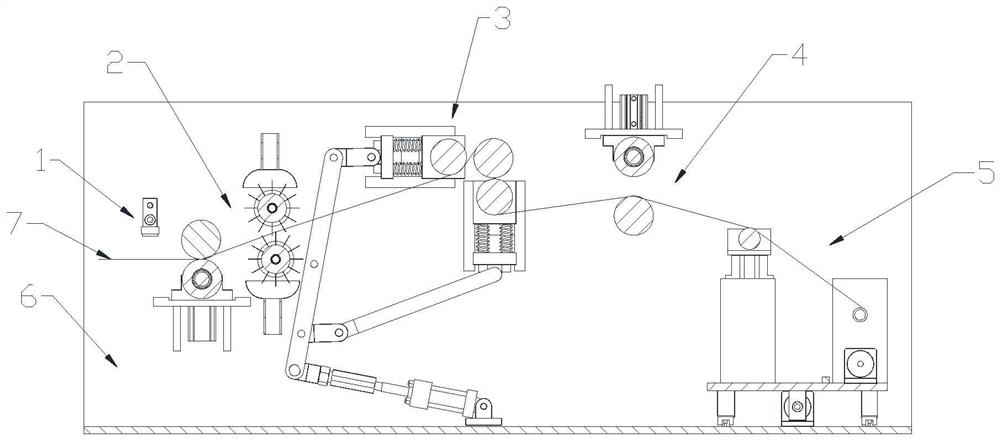

Catheter supply device and catheter supply and cutting equipment

ActiveCN106272661BUninterrupted supplyOperation without downtimeMetal working apparatusCatheterEngineering

The invention discloses a conduit supply device, and conduit supply and cutting equipment. The conduit supply device comprises at least two guide sleeves, at least two guide parts and a first moving component, wherein the at least two guide sleeves are arranged to receive conduits from a conduit winding frame, the at least two guide parts are arranged to respectively receive the conduits from at least two guide sleeves, and the first moving component is arranged at the downstream of the at least two guide sleeves and can move the conduits towards a direction away from the at least two guide sleeves. According to the conduit supply device disclosed by the invention, uninterrupted conduit supply can be realized without shutdown operation, and therefore working efficiency is increased.

Owner:MAIDER MEDICAL IND EQUIP

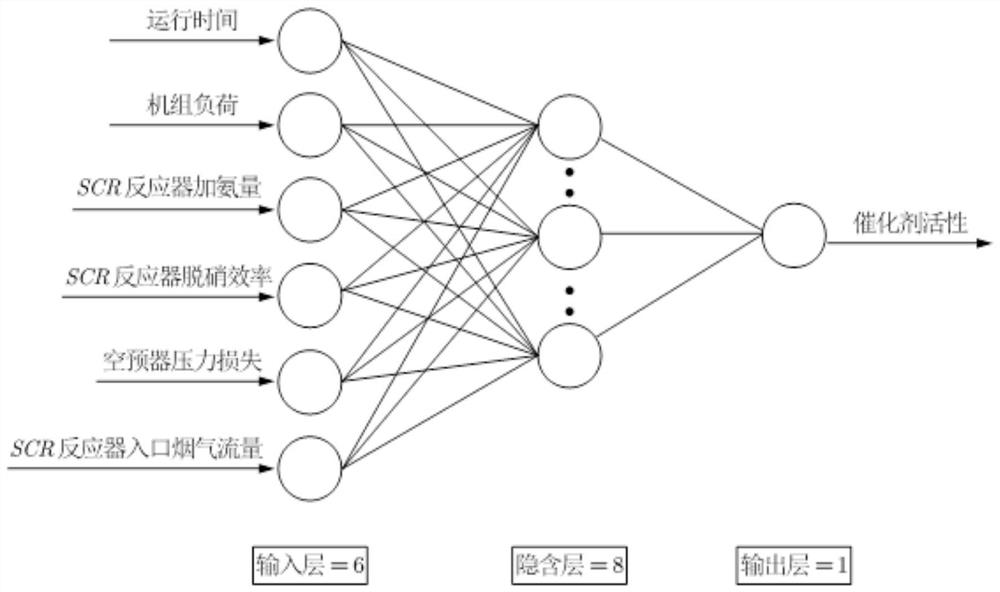

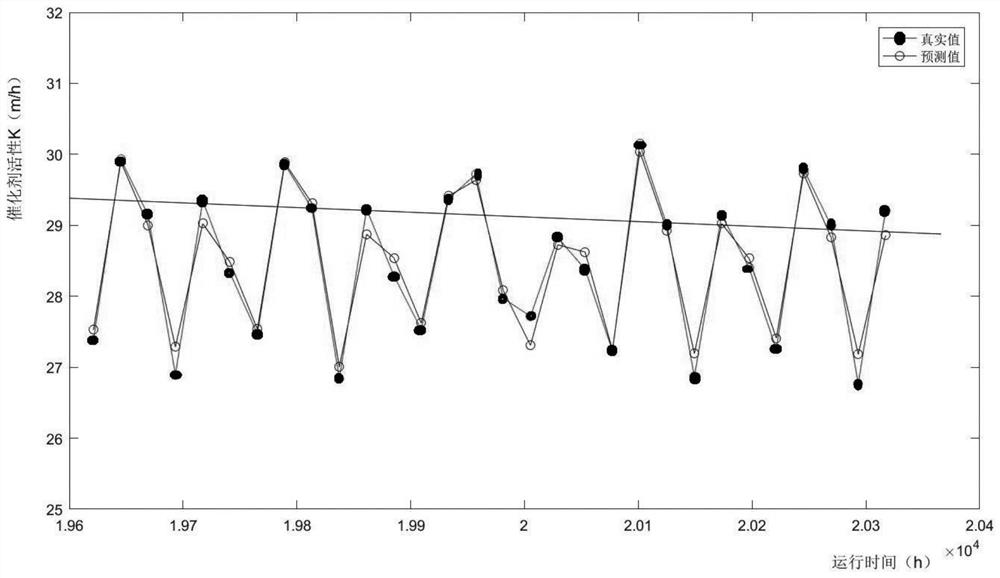

SCR catalyst life prediction method based on BP neural network algorithm

PendingCN114201919ADoes not affect normal workAccurately predict structureDesign optimisation/simulationPtru catalystAlgorithm

The invention relates to an SCR catalyst life prediction method based on a BP neural network algorithm, and belongs to the technical field of power plant denitration. According to the SCR catalyst life prediction method based on the BP neural network algorithm, data mining is carried out on DCS data of the denitration system, key indexes of catalyst activity are obtained, the BP neural network algorithm is used for more accurately predicting the change trend of the catalyst activity, a theoretical basis is provided for catalyst management of the denitration system, the prediction structure is accurate, and the prediction cost is low. Shutdown operation of a power plant denitration system is not needed, and normal work of a power plant is not affected.

Owner:国家能源集团谏壁发电厂 +1

Velvet fabric textile fabric plane printing device and using method thereof

PendingCN114211870AImprove regulation efficiencyOperation without downtimeMechanical cleaningPressure cleaningTextile printerRemoving hair

The invention discloses a velvet fabric textile fabric plane printing device which comprises a support, an identification assembly, a hair removal assembly, a printing assembly, an ironing assembly and a rolling assembly are arranged in the support, the hair removal assembly is arranged on one side of the identification assembly, the printing assembly is arranged on one side of the hair removal assembly, the ironing assembly is arranged at one end of the printing assembly, and the rolling assembly is arranged on the other side of the printing assembly. A winding assembly is arranged at one end of the ironing assembly, and the velvet fabric penetrates through the recognition assembly, the fluff removing assembly, the printing assembly and the ironing assembly and is finally wound by the winding assembly. According to the plane printing device, the color and width of the velvet fabric can be automatically recognized before printing, corresponding follow-up operation is conducted according to the color and width of the velvet fabric, the rolling assembly moves for rolling, the printing assembly adjusts the contact mode of the first liquid outlet cylinder, the printing cylinder and the second liquid outlet cylinder, the overall adjusting efficiency is high, and shutdown operation is not needed; the velvet fabric can be automatically subjected to pressing, impurity removal, dyeing and printing, ironing and rolling.

Owner:ANHUI UNIV OF SCI & TECH

Hot melting device for new material production

PendingCN114523649AEasy to fixEasy to cleanPlastic recyclingProcess engineeringMechanical engineering

The invention discloses a hot melting device for new material production, and relates to the field of new material production. The hot melting device for new material production comprises a hot melting device extrusion pipe, a filter screen installation base is fixedly installed in the middle of the hot melting device extrusion pipe, a first filter screen is fixedly installed at the position, close to the filter screen installation base, of an inner cavity of the hot melting device extrusion pipe, and an opening is formed in the side face of the filter screen installation base; and the inner cavity of the filter screen mounting seat is wider than that of the extrusion pipe of the hot melting device. According to the hot melting device for new material production, the first filter screen and the second filter screen can be conveniently installed and fixed, so that when a new material passes through an extrusion pipe of the hot melting device, the new material is filtered, residues are taken out, when the second filter screen is installed and fixed, operation is easy and convenient, time and labor are saved, and the production efficiency is improved. In the later period, the first filter screen and the second filter screen are convenient to take out and clean and easy to replace, and the aperture of a filter hole formed by the first filter screen and the second filter screen is adjustable.

Owner:李岩

One kind of connecting rod cover double -end surface processing automatic material clothing

ActiveCN112621344BReduce manual labor intensityImprove work efficiencyWork clamping meansMilling equipment detailsDrive shaftEngineering

Owner:襄阳鼎超机械制造有限公司

Etching device for solar cell production

ActiveCN108511370BSimple structureAutomate operationFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringStructural engineering

The invention discloses an etching device for producing a solar cell, comprising an etching groove and a spraying device mounted on the etching groove, wherein a material inlet is formed on the frontsurface of the etching groove, and a material outlet matching the material inlet is formed on the rear surface of the etching groove; an etching liquid tank is arranged on the outer surface of the left side of the etching groove; a waste liquid collecting tank is arranged on the right surface of the etching groove; a connection cross beam is fixed on the edge on the top of the left side surface ofthe etching groove; a worm is fixed on the surface of the connection cross beam in a penetration manner; a spraying device comprises a spray pipe; a worm gear is fixed on the surface of the spray pipe; the left end of the spray pipe is connected with a liquid inlet pipe through a shaft sleeve; and the right end of the spray pipe is connected with a liquid outlet pipe through a shaft. The etchingdevice of the invention has the advantages of simple structure, automatization of operation, uniform spraying of the etching liquid, uniform etching effect, as well as the advantages of high utilization rate, strong cleaning ability and no secondary pollution.

Owner:重庆赛帕斯汽车零部件股份有限公司

A Method for Determining "Dynamometer Diagram" of Electrical Parameters of Pumping Units

ActiveCN104533382BFulfill management needsRealize online continuous automatic usability measurementSurveyConstructionsElectricityTop dead center

The invention provides a method for determining an indicator diagram of electrical parameters of a rod-pumped well and belongs to the technical field of oil production of oil fields. The method aims at achieving convenient and practical measurement of the indicator diagram of the electrical parameters of the rod-pumped well on site. The method is characterized in that top dead center moments and bottom dead center moments are determined periodically, active powers of electrical parameters of up strokes and down strokes of the rod-pumped well are processed in a decomposition mode, and input end active power of the up strokes and the down strokes is obtained respectively and are calculated and converted into wellhead loading force; adjustment is conducted through balance blocks for operation balance of a pumping unit, actually measured data are used for further correcting the weights of the crank balance blocks of the oil pumping unit or retrieving the weights of the crank balance blocks after adjustment, actually measured active power is converted into wellhead loading force F<upper force i>, wellhead loading force F<lower force i> and superposed wellhead loading force F<upper and lower force i>, the wellhead loading force F<upper force i>, the wellhead loading force F<lower force i> and the superposed wellhead loading force F<upper and lower force i> are calculated, superposed and converted into wellhead loading force, and the indicator diagram of trends of the electrical parameters is determined before and after superposition with the crank balance blocks. According to the method, on-site testing is convenient and practical, and online automatic measurement is achieved.

Owner:哈尔滨斯特凯峰电子有限公司

An automatic feeding device for end face processing

ActiveCN112720032BHigh degree of automationImprove processing efficiencyPositioning apparatusMetal working apparatusControl engineeringProcess engineering

The invention relates to the technical field of parts processing, and discloses an automatic feeding device for end face processing, comprising a pushing device, an automatic positioning device and a discharging device. The workpiece to be processed is continuously transported to the automatic positioning device through the pushing device for positioning and clamping, and The material is discharged through the unloading device to realize the continuous automatic end face processing process, which has a high degree of automation and high work efficiency. In addition, the conveying mechanism in the automatic positioning device uses the eccentric shaft to drive the conveying wheel to perform eccentric rotation movement to realize the clamping and conveying of the workpiece. During the movement of the wheel to convey the workpiece, on the one hand, the conveying path of the workpiece is extended, and the diameter of the conveying wheel required for conveying workpieces of the same size is reduced, thereby reducing the volume of the equipment and reducing the cost of the equipment. On the other hand, the conveying wheel During the eccentric motion, the positioning mechanism can also be driven to realize the positioning of the workpiece, which ensures the synchronization between the positioning mechanism and the conveying mechanism, and the positioning mechanism does not require additional power, and the equipment cost is low.

Owner:襄阳鼎超机械制造有限公司

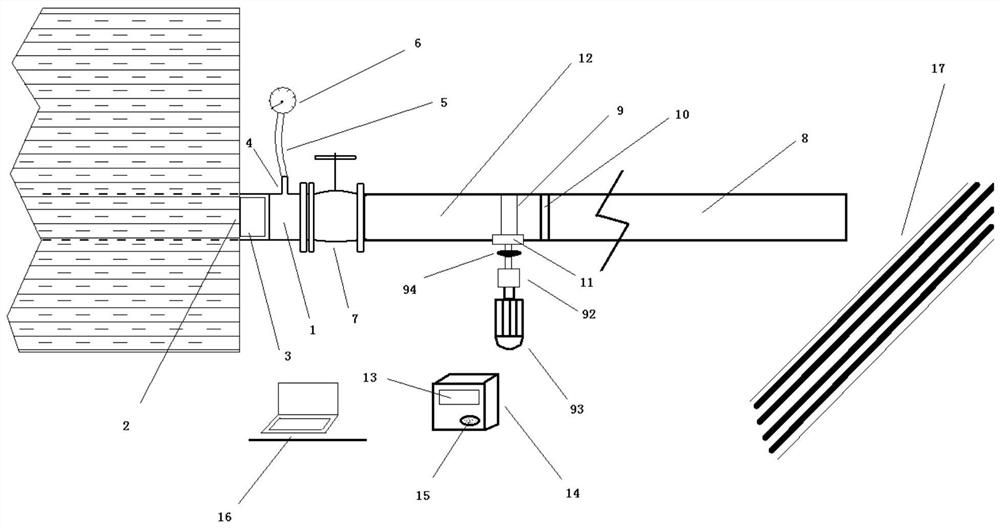

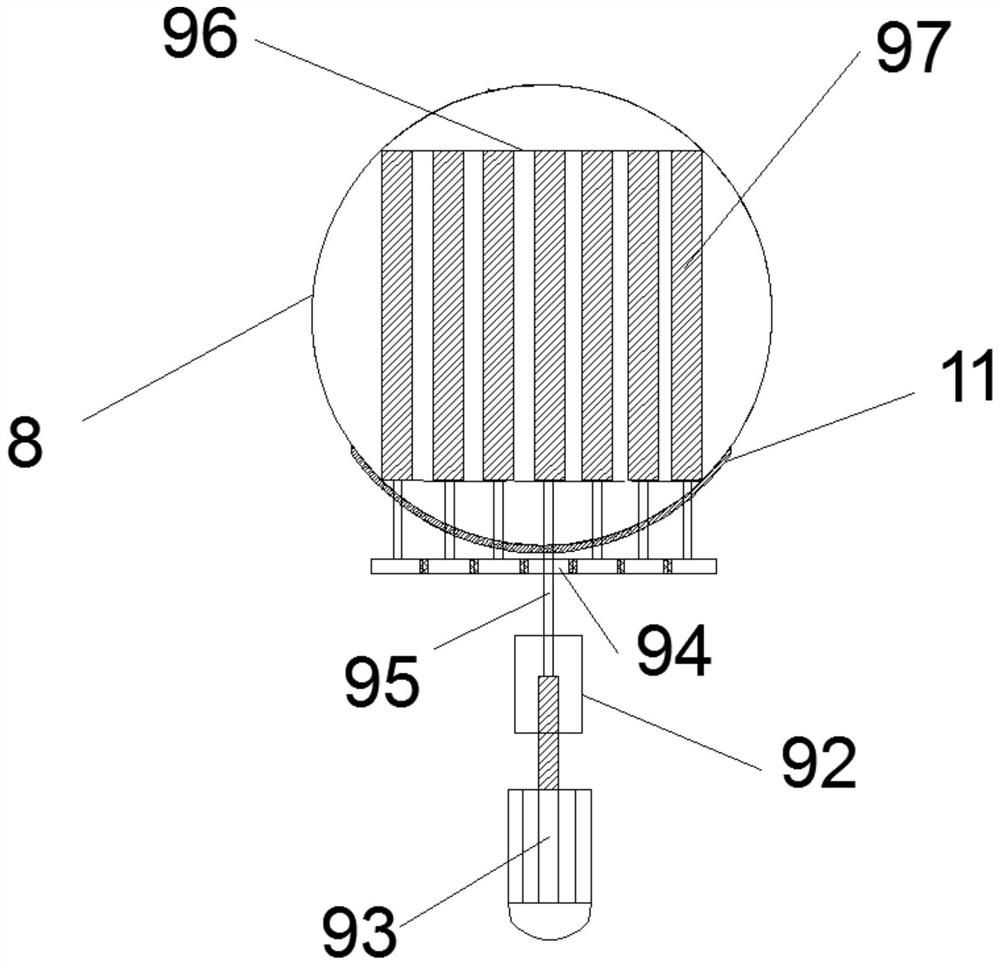

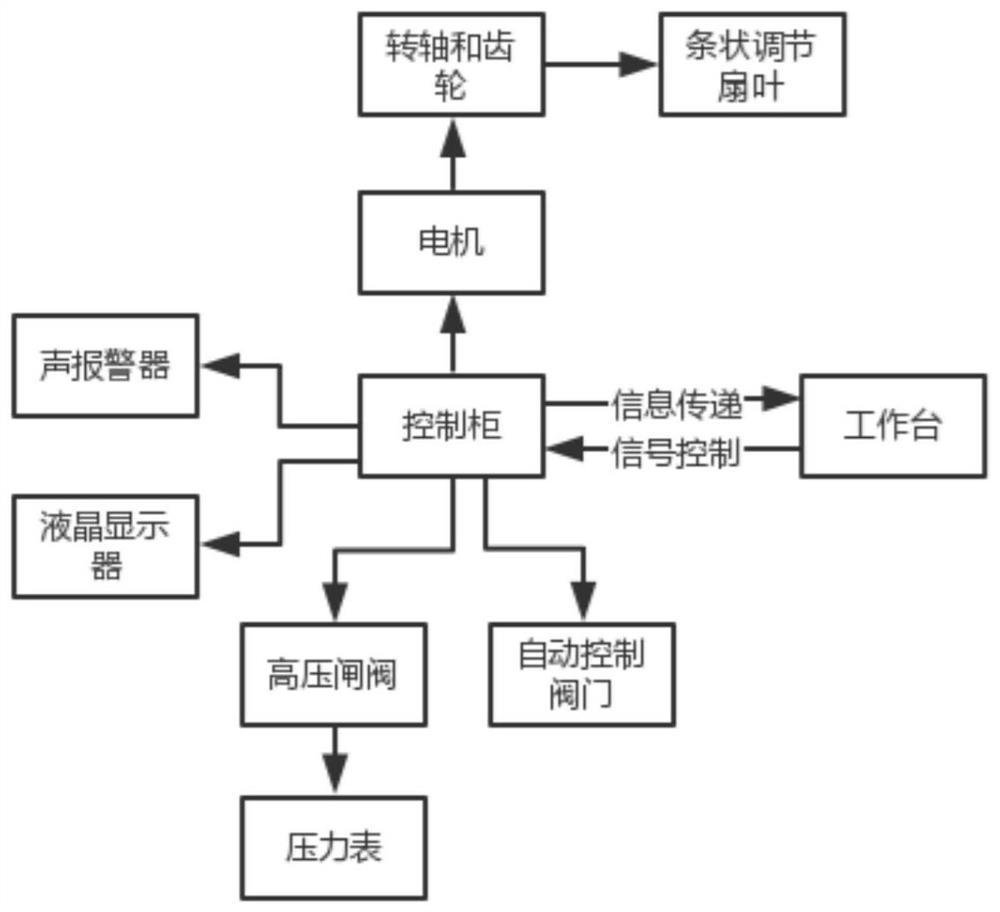

Portable pressure regulating and measuring device for underground water exploration and drainage

PendingCN112049684ANo manual operationHigh degree of automationOperating means/releasing devices for valvesMining devicesInformation processingTube drainage

The invention discloses a portable pressure regulating and measuring device for underground water exploration and drainage. The device comprises a high-pressure oil pipe, a water passing pipeline anda drainage pipeline which are connected through the high-pressure oil pipe, a pup joint sleeve is arranged to connect the water passing pipeline and the high-pressure oil pipe, the drainage pipeline is connected with the high-pressure oil pipe through a high-pressure oil pipe connector, and the drainage pipeline leads to a drainage ditch. A water pressure measuring mechanism is arranged at one side of the pup joint sleeve, and the signal output end of a core control mechanism is connected with the signal input end of the water pressure measuring mechanism; a water pressure adjusting mechanismis further arranged in the drainage pipeline, the signal output end of the core control mechanism is connected with the signal input end of the water pressure adjusting mechanism, a communication serial port of an information processing mechanism is connected with the core control mechanism, and the signal output end of the core control mechanism is connected with the signal input end of the waterpressure measuring mechanism; and the water pressure measuring mechanism is connected with the communication serial port of the information processing mechanism through the core control mechanism. According to the scheme, pressure measurement can be facilitated, and timely and non-stop pressure regulation can be completed.

Owner:HUAIBEI MINING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com