A Method for Determining "Dynamometer Diagram" of Electrical Parameters of Pumping Units

A technology for pumping wells and determination methods, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc. It can solve problems such as difficult analysis process, and achieve practicality, simple and convenient practical measurement, and convenient and practical testing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

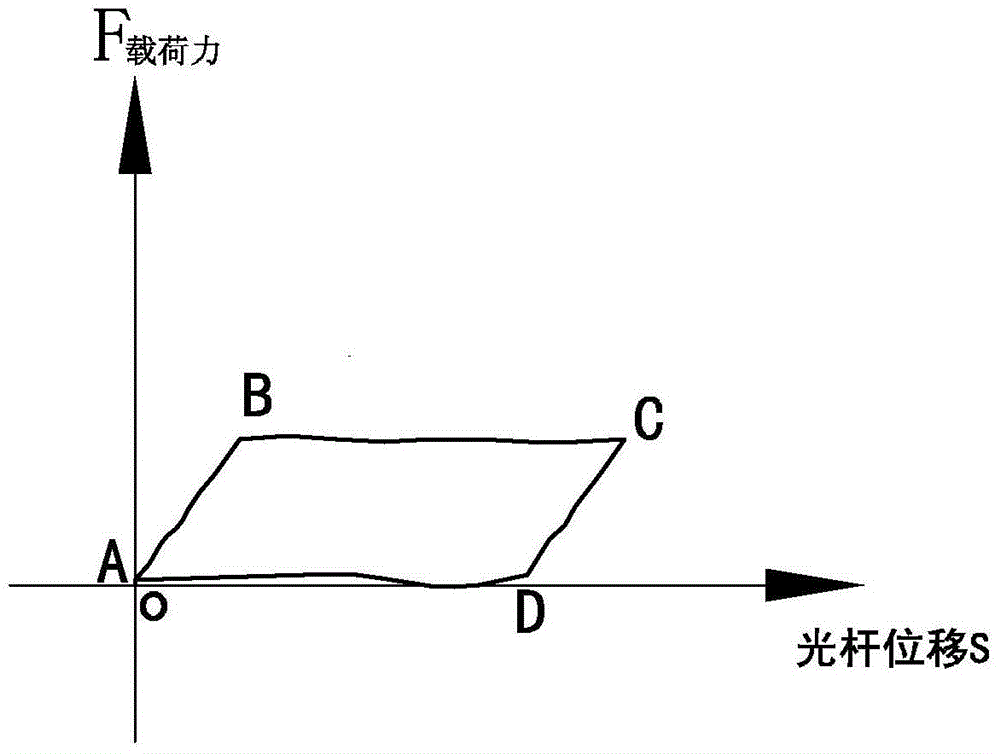

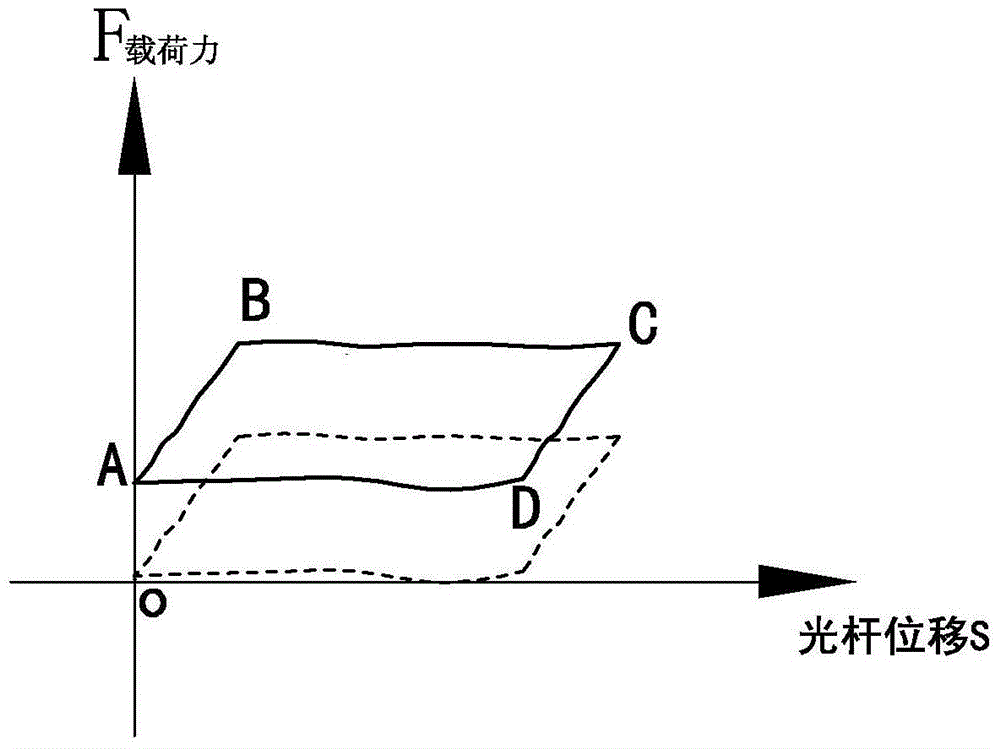

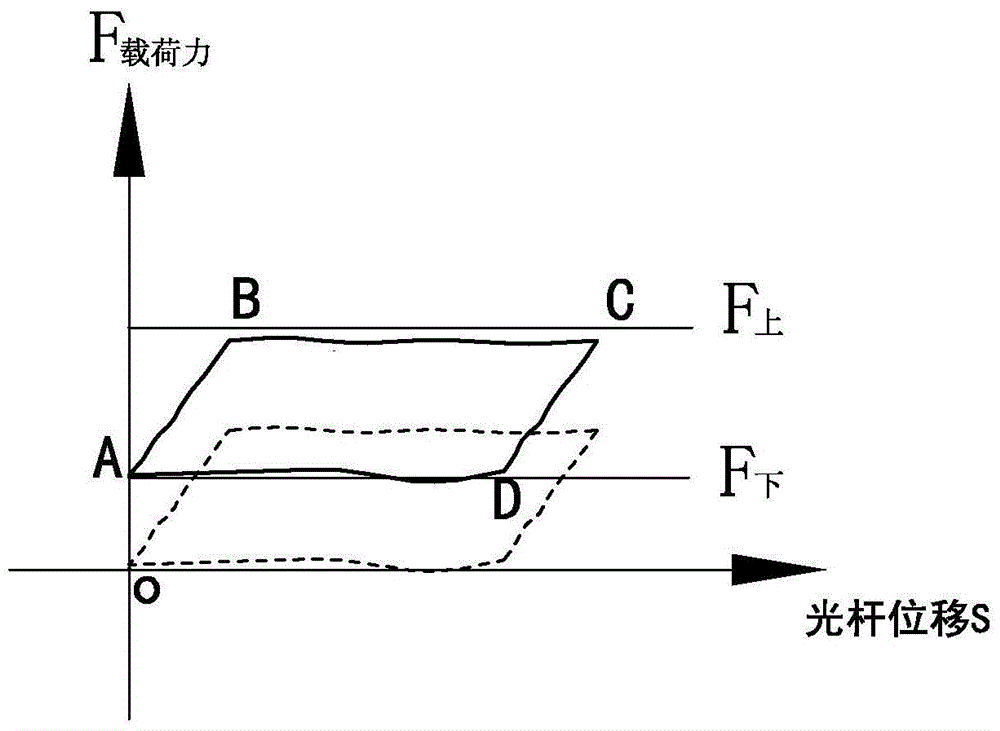

[0029] Specific implementation mode one: as Figure 1~3 As shown, the determination method of the pumping unit well electrical parameters "demonstration diagram" described in the present embodiment is to convert the pumping unit well electrical parameters and the average stroke to the wellhead load force and displacement to determine the "demonstration diagram" (i.e. Determine the "dynamometer diagram" by converting to wellhead load force displacement), the implementation process of the method is:

[0030] Step 1. During the normal working process of the pumping unit, collect the electrical parameters of the pumping well in real time at high speed, measure the electrical parameters of the motor input terminal: current, voltage, active power, and the data acquisition speed is greater than or equal to 20 times per second. The moment when the crank of the oil rig runs to the upper dead point and the lower dead point corresponding to the suspension point of the wellhead of the pum...

specific Embodiment approach 2

[0059] Specific embodiment two: the process of the adjustment method of a kind of pumping well operation balance described in the present embodiment is:

[0060] Step 1. During the normal working process of the pumping unit, collect the electrical parameters of the pumping well in real time at high speed. The data collection speed is greater than or equal to 20 times per second. Simultaneously measure the electrical parameters of the motor input terminal: current, voltage, active power, and determine the pumping unit. The moment when the crank of the pumping unit runs to the upper dead point of the suspension point of the wellhead of the pumping unit and the moment to the lower dead point;

[0061] Pumping unit stroke: the crank balance weight of the pumping unit runs to the bottom dead center of the corresponding pumping unit wellhead (the crank operating angle is 0° or 360°), and the crank balance weight of the pumping unit runs to the top dead center of the corresponding pum...

specific Embodiment approach 3

[0066] This embodiment describes the second specific embodiment in detail. Give an example to illustrate the net torque superposition value P of the up and down strokes for multiple consecutive strokes 上下 The calculation process, assuming that it is required to obtain the net torque superposition value P of up and down strokes for m consecutive strokes 上下 and the torque factor of m strokes

[0067] The net torque data collected on the upstroke of the first stroke is X 1 、X 2 、X 3 ,...X n , then the average value P of all net torques in the upstroke in this stroke 1上 For: (X 1 +X 2 +X 3 +…+X n ) / n;

[0068] The torque factor calculated corresponding to the upstroke of the first stroke and data acquisition is Z 1 ,Z 2 ,Z 3 ,……Z n , then the average value of all torque factors in the upstroke in this stroke For: (Z 1 +Z 2 +Z 3 +…+Z n ) / n;

[0069] The net torque data collected on the downstroke of the first stroke is Y 1 , Y 2 , Y 3 、…Y n , then the ave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com