Experimental determining method of retention in tobacco material roller in processing flow

A technology of tobacco materials and measurement methods, which is applied in the field of tobacco processing, can solve the problems of inability to determine the change information of the retention volume of drum materials, cumbersome operations, etc., and achieve the effect of simple and easy measurement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

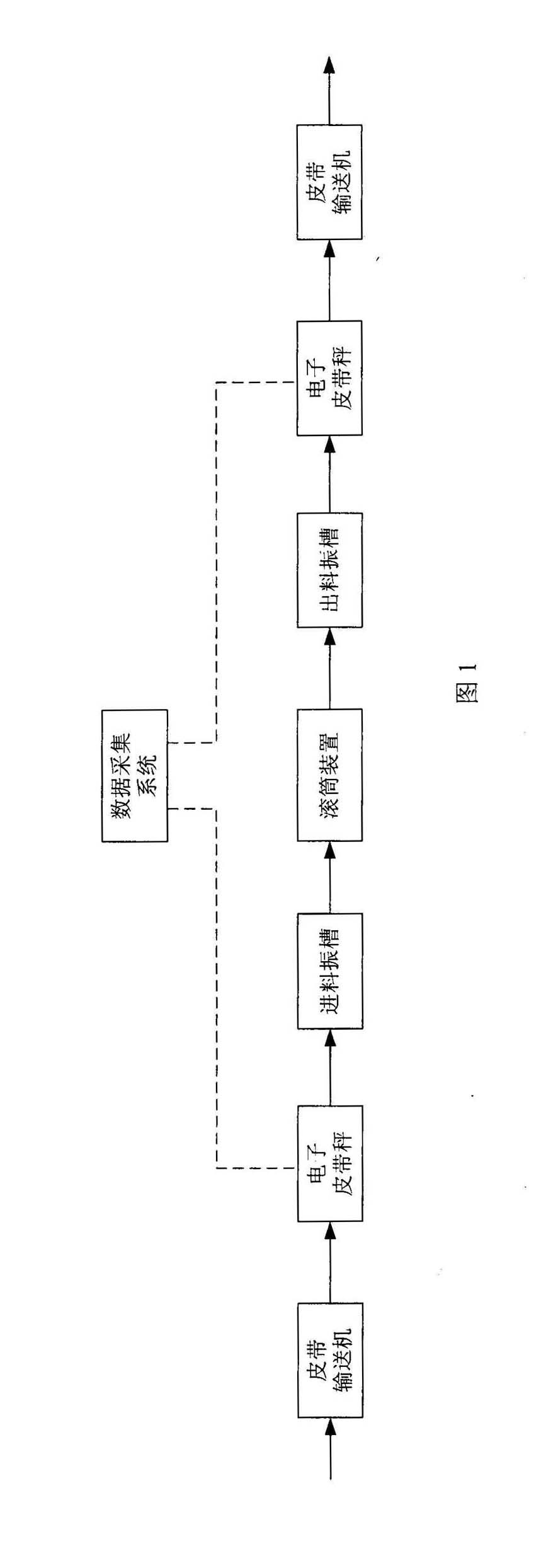

[0041] Such as figure 1 As shown, the present invention is equipped with electronic belt scales at the front end and rear end of the drum equipment respectively to measure the real-time mass flow rate of the material before and after the material flows through the drum, and the mass flow data measured by the electronic belt scales are collected and recorded through the data acquisition system.

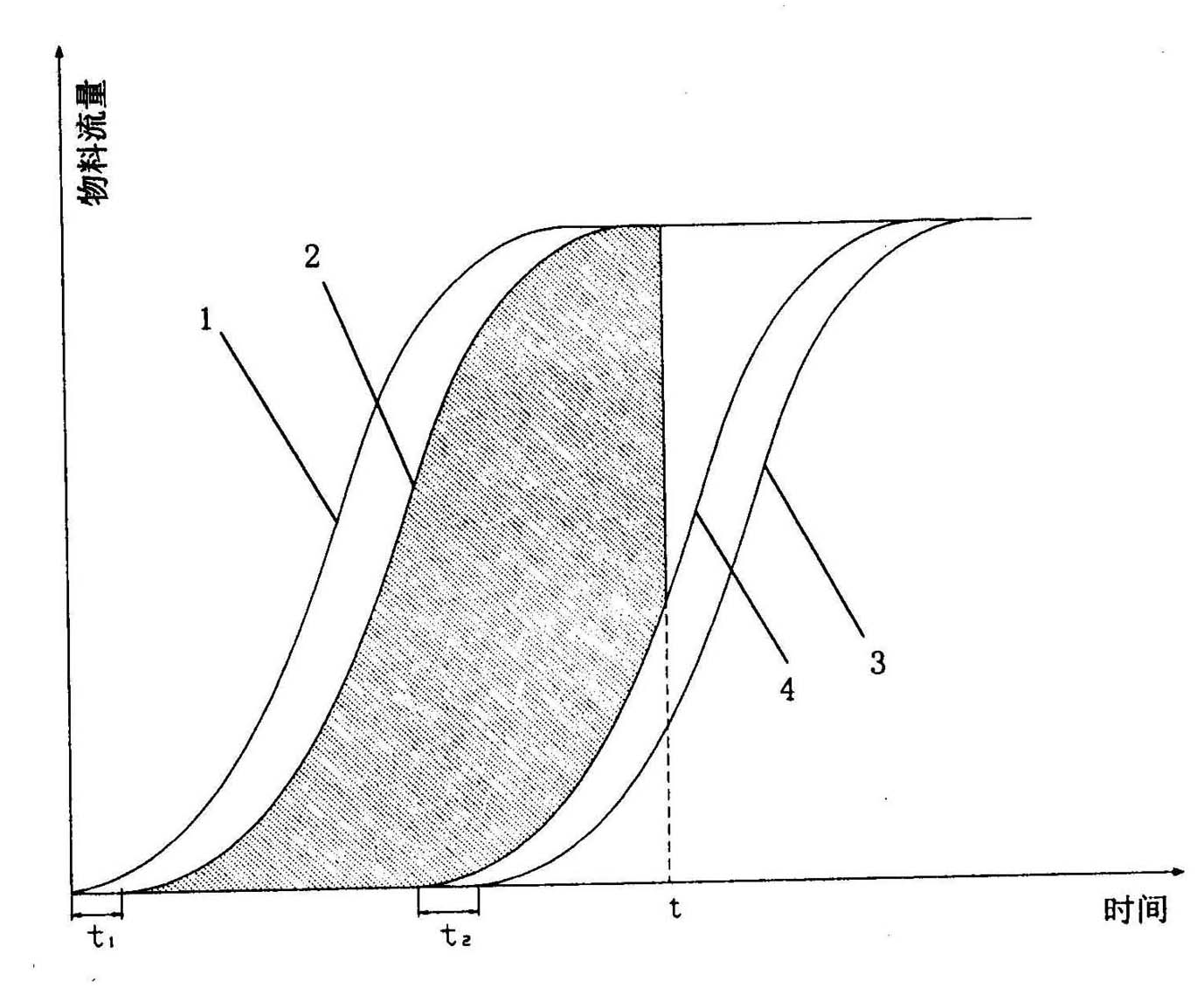

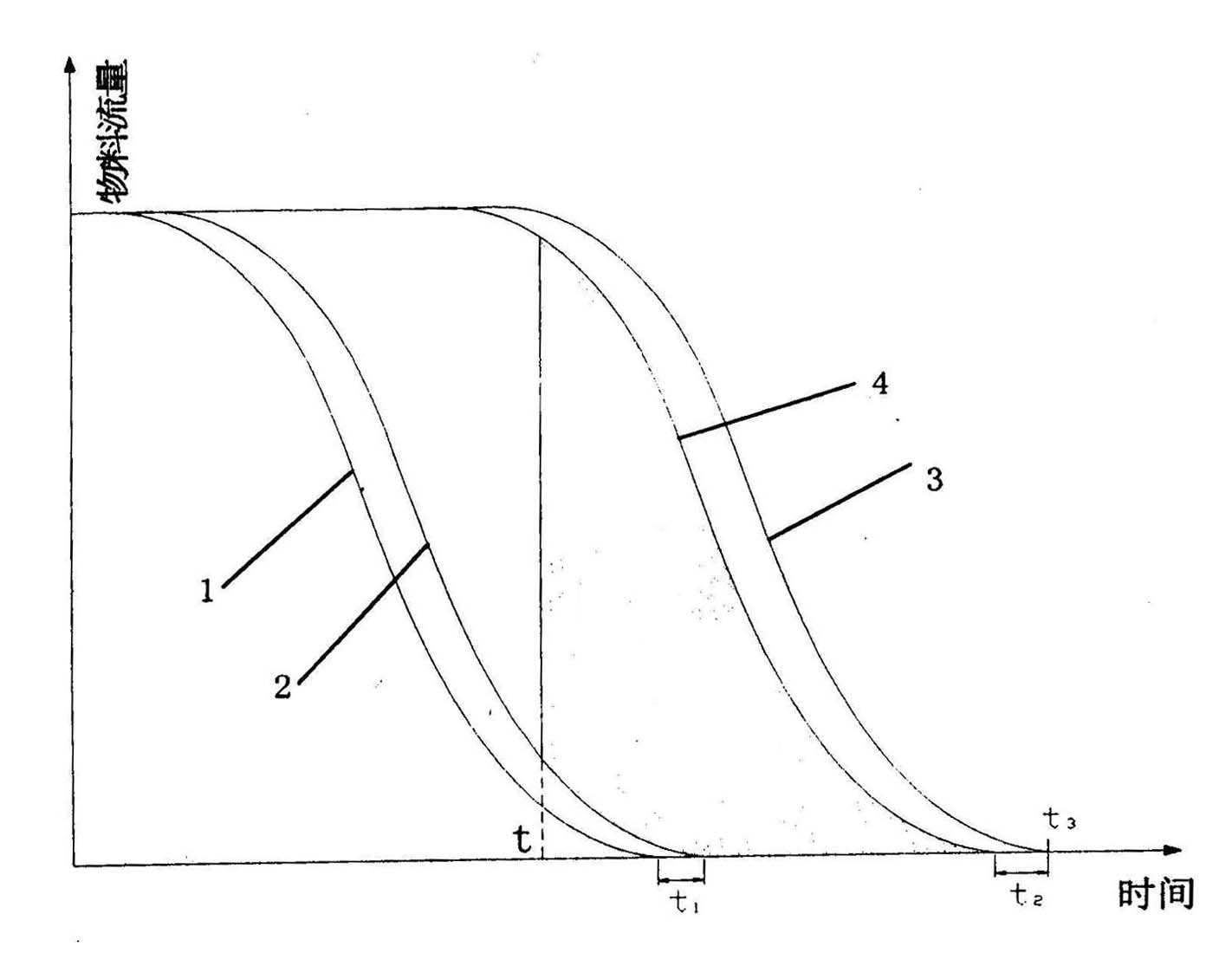

[0042] Specifically, the experimental measurement method of the present invention includes a method for measuring the retention volume of the tobacco material cylinder at the head stage and a determination method for the retention volume of the tobacco material cylinder at the tail stage;

[0043] Wherein the assay method of tobacco material drum retention in the head stage of the material comprises the following steps:

[0044] In the material head stage, start timin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com