Hot melting device for new material production

A hot-melt device and new material technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems that the hot-melt device cannot meet the needs of users, the mesh aperture cannot be changed, and the filter screen is inconvenient to install and fix, etc., to achieve easy replacement , not easy to loose, fixed and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

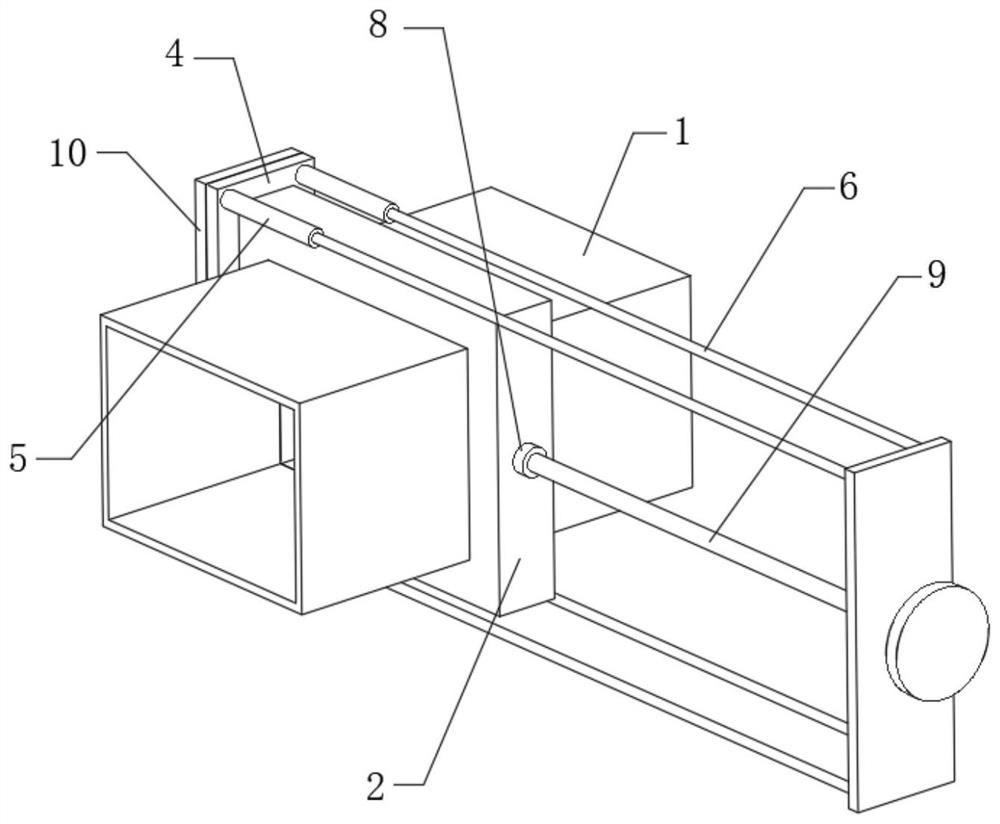

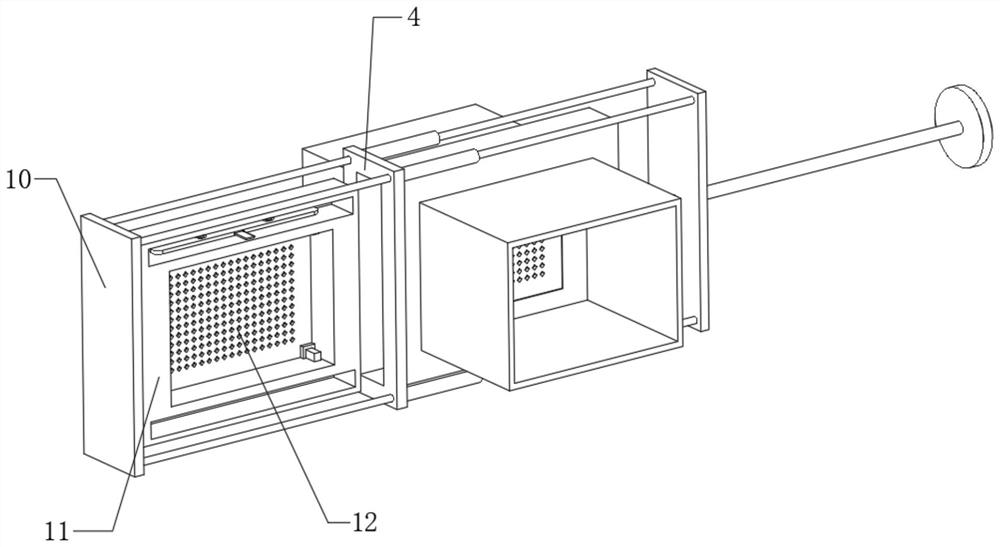

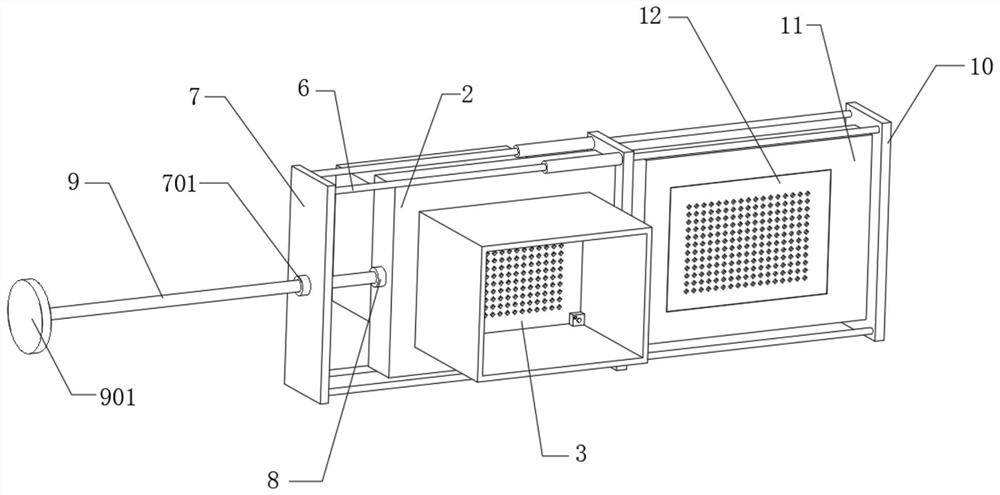

[0030] The embodiment of the present invention discloses a hot-melt device for the production of new materials, such as Figure 1-8 As shown, it includes a hot-melt device extrusion pipe 1, a filter screen mounting seat 2 is fixedly installed in the middle of the hot-melt device extrusion pipe 1, and the inner cavity of the hot-melt device extrusion pipe 1 is fixedly installed at a position close to the filter screen mounting seat 2 There is a first filter screen 3, the side of the filter screen mounting seat 2 is provided with an opening, the inner cavity width of the filter screen mounting seat 2 is larger than the inner cavity width of the extrusion pipe 1 of the hot-melt device, and the side surface of the filter screen mounting seat 2 is fixedly connected with a panel 4. The four corners of the panel 4 are fixedly connected to the limit tube 5, the lumen of the limit tube 5 is slidably connected with a sliding rod 6, the side walls of the four sets of sliding rods 6 are fi...

Embodiment 2

[0042] The embodiment of the present invention discloses a hot-melt device for the production of new materials, such as Figure 1-8 As shown, it includes a hot-melt device extrusion pipe 1, a filter screen mounting seat 2 is fixedly installed in the middle of the hot-melt device extrusion pipe 1, and the inner cavity of the hot-melt device extrusion pipe 1 is fixedly installed at a position close to the filter screen mounting seat 2 There is a first filter screen 3, the side of the filter screen mounting seat 2 is provided with an opening, the inner cavity width of the filter screen mounting seat 2 is larger than the inner cavity width of the extrusion pipe 1 of the hot-melt device, and the side surface of the filter screen mounting seat 2 is fixedly connected with a panel 4. The four corners of the panel 4 are fixedly connected to the limit tube 5, the lumen of the limit tube 5 is slidably connected with a sliding rod 6, the side walls of the four sets of sliding rods 6 are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com