Method for serially connecting a plurality of water pumps by using hoses

A water pump and hose technology, which is applied in the field of non-variable-capacity pumps, can solve the problems that the water pumps cannot be connected by hoses in series, inconvenient transportation, and the phenomenon of straws, and achieves the effect of quick and convenient dismantling and flexible use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

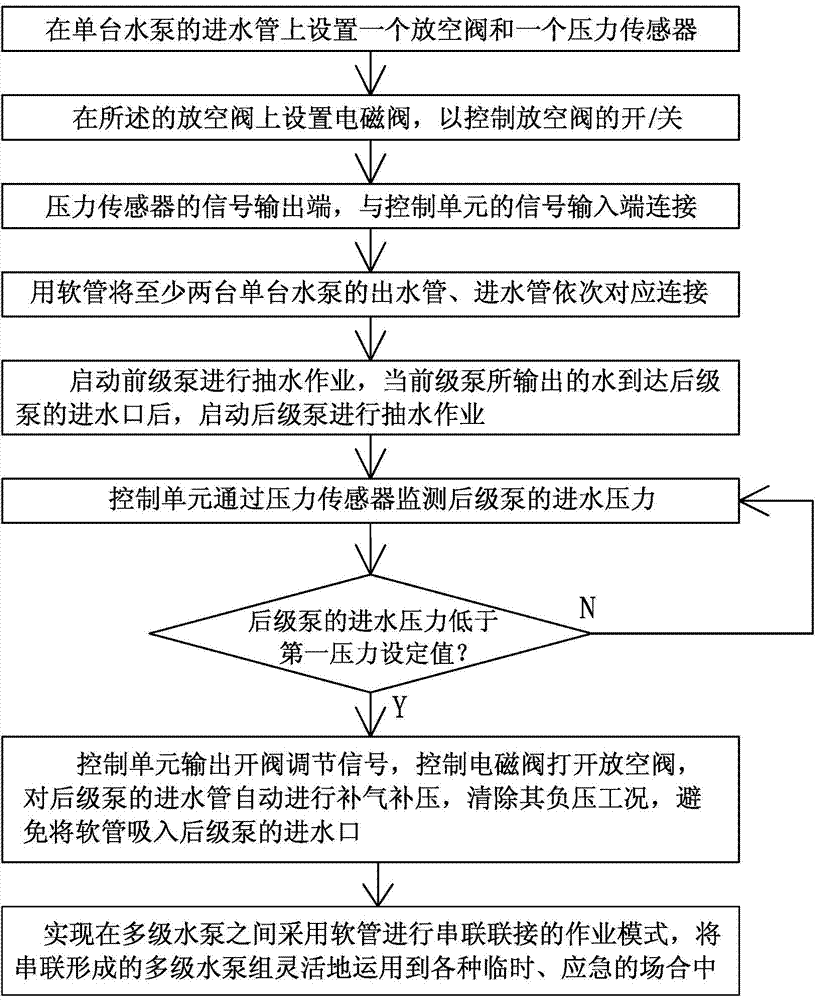

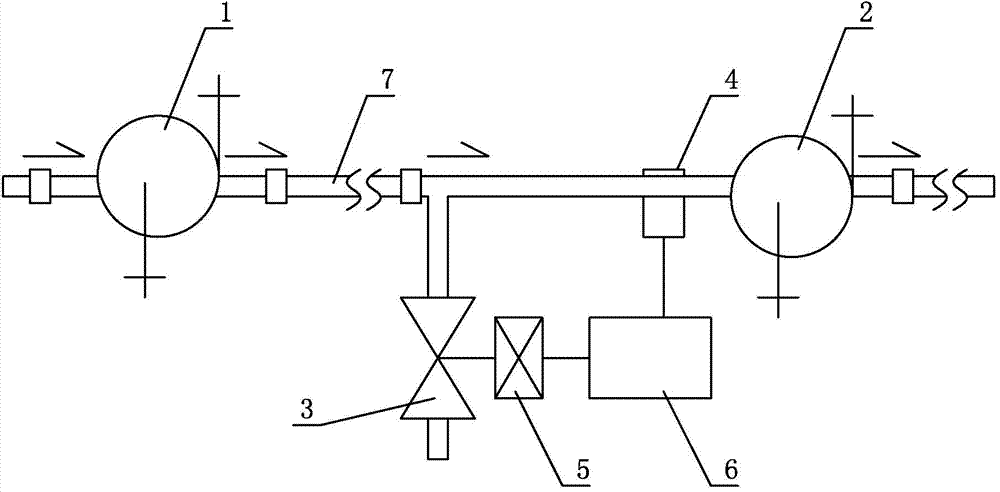

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

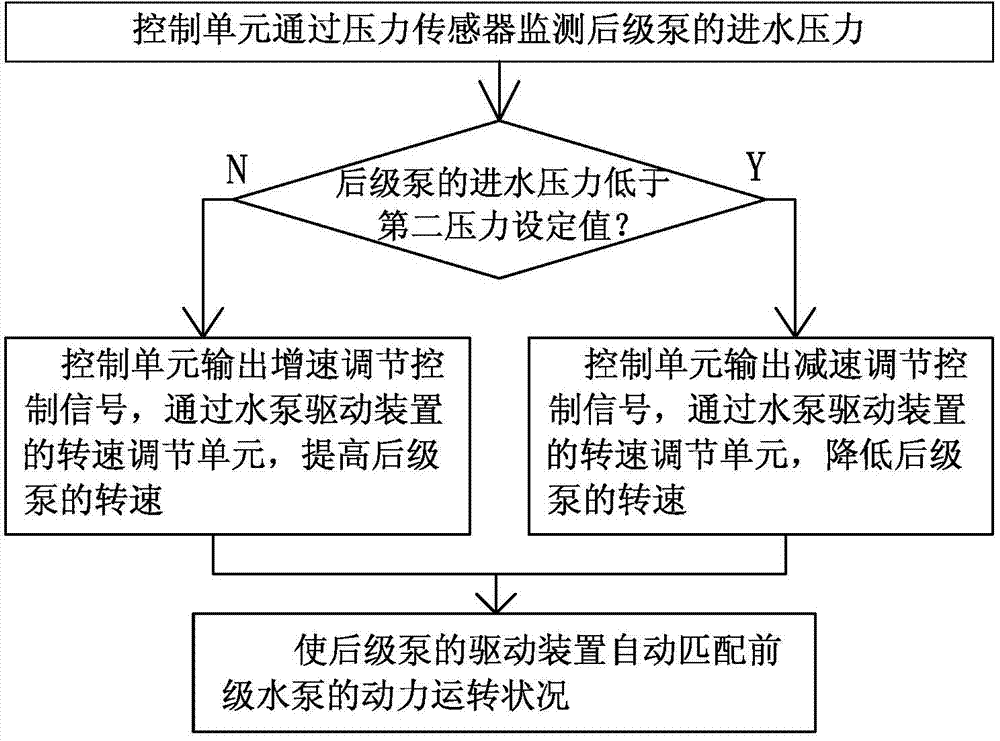

[0033] figure 1 Among them, the technical solution of the present invention provides a method for connecting hoses of multiple water pumps in series, which firstly installs a vent valve and a pressure sensor on the water inlet pipe of a single water pump; Control the opening / closing of the vent valve; connect the signal output end of the pressure sensor with the signal input end of a control unit; connect the signal output end of the control unit with the control signal input end of the solenoid valve correspondingly.

[0034]After constructing the above-mentioned hardware composition and control wiring mode on a single movable / portable water pump, use hoses to connect the outlet pipes and water inlet pipes of at least two single water pumps in sequence, and connect the first single water pump One water pump is used as a backing pump, and the second si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com