Air bag used for water treatment, and water purification device with same

A technology of water treatment device and water purification device, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc. Problems such as dripping, frequent start-up of the booster pump, etc., achieve the effect of compact structure, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

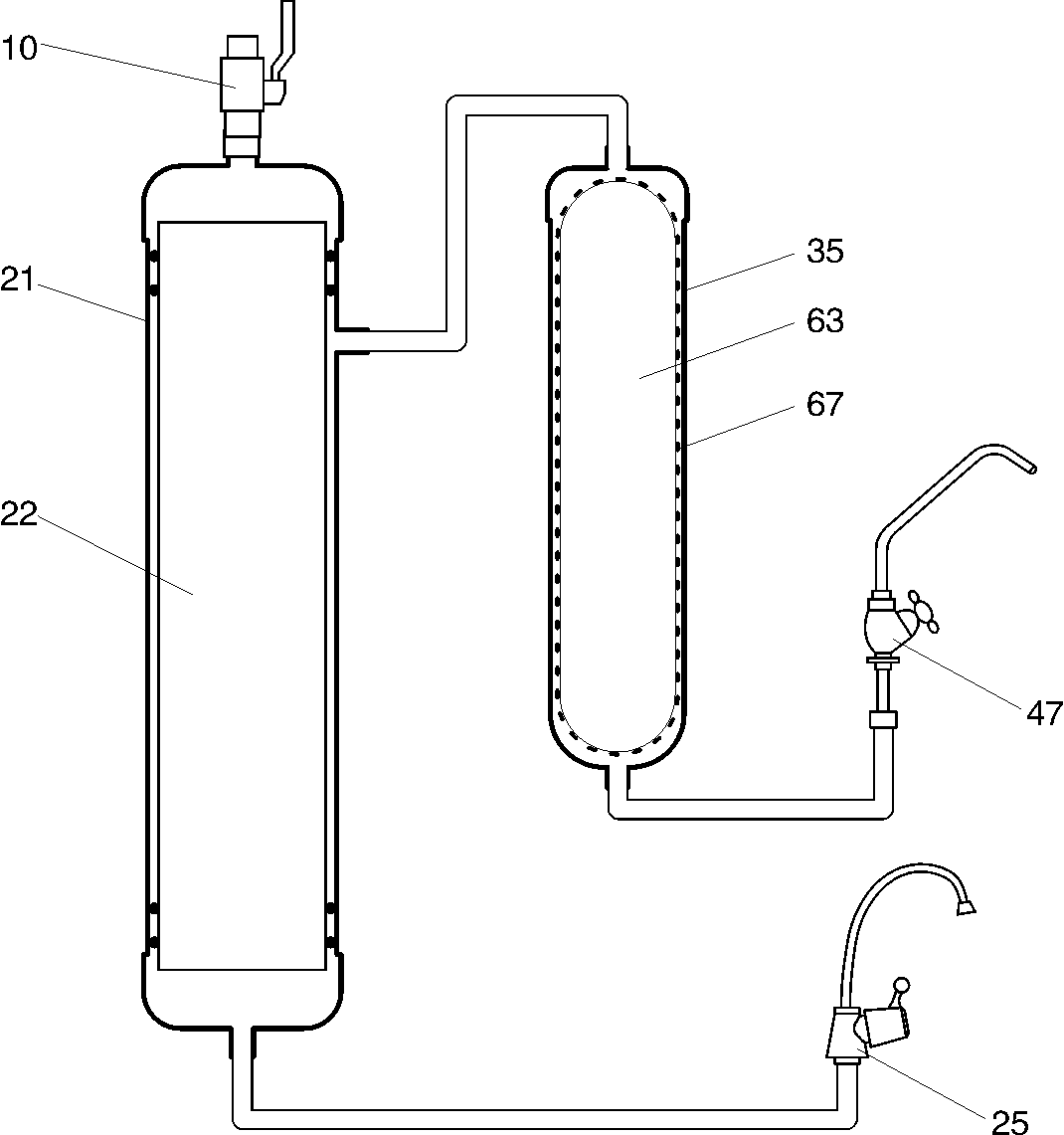

[0056] Embodiment 1 is a kind of ultrafiltration water purifier with airbag backwash, figure 1 It is the structural representation of embodiment 1.

[0057] Structure of Embodiment 1

[0058] The present embodiment is mainly made up of ultrafiltration filter element 22, air bag 63 and its ultrafiltration filter housing 21, filter housing 35; the ultrafiltration filter element 22 is an internal pressure hollow fiber ultrafiltration filter element, which is installed in the ultrafiltration filter housing 21; the air bag 63 is composed of It is made of high-impermeability multi-layer composite plastic film, filled with nitrogen inside, with diversion net sleeve 67 on the outside, installed in filter housing 35; ultrafiltration filter housing 21 is provided with water inlet, water purification port and flushing port, water inlet It is connected to the water inlet valve 10 , the flush port is connected to the flush valve 25 , and the water purification port is connected to the wa...

Embodiment 2

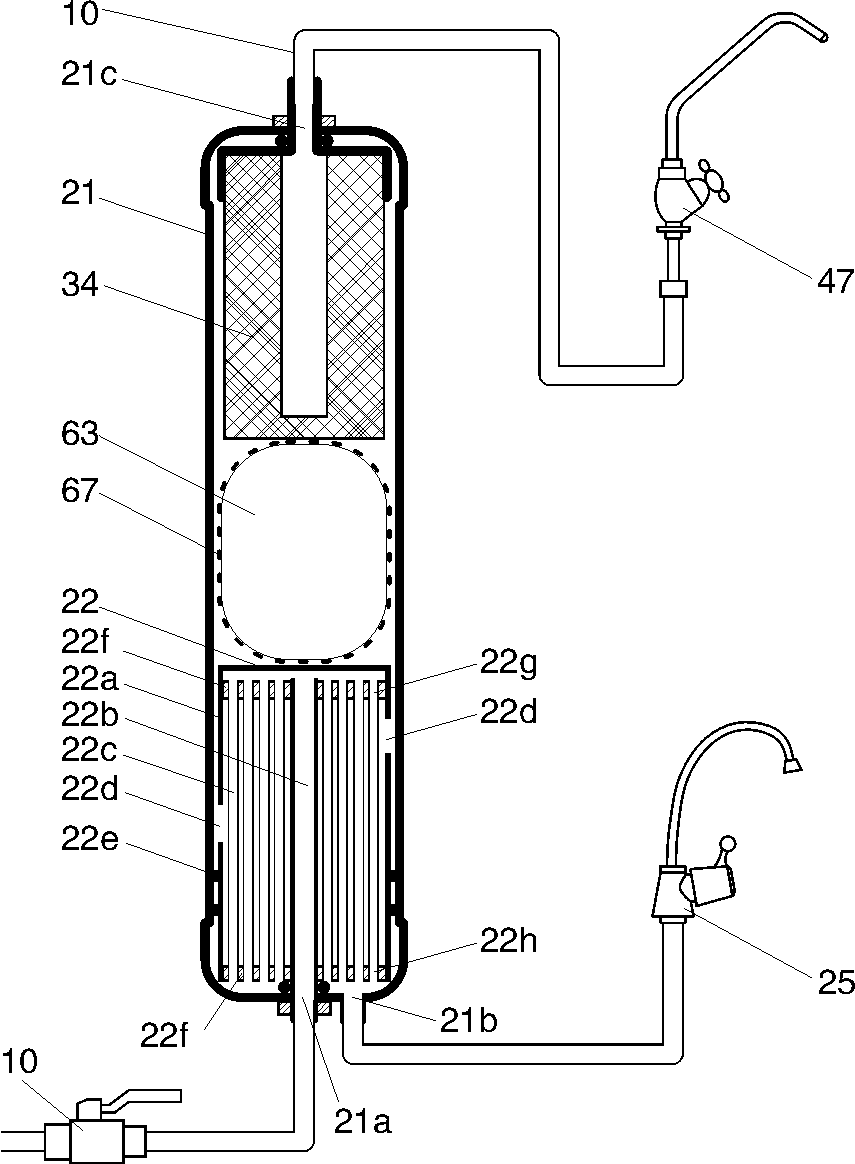

[0069] Embodiment 2 is an integrated ultrafiltration water purifier with air bag backwashing, figure 2 It is the structural representation of embodiment 2.

[0070] Structure of Embodiment 2

[0071] This embodiment is mainly composed of an ultrafiltration filter element 22, an air bag 63, an activated carbon filter element 34 and an ultrafiltration filter housing 21; one end of the ultrafiltration filter housing 21 is provided with a water inlet 21a and a flushing port 21b, and the other end is provided with a water purification port 21c The ultrafiltration filter element 22 is bonded with a sealant 22f by the shell 22a, the central tube 22b, and the ultrafiltration membrane wire 22c, and is installed in the ultrafiltration filter shell 21, and is sealed and fastened at the water inlet 21a of the ultrafiltration filter shell 21 The shell 22a of the ultrafiltration element 22 has a clean water port 22d, which is open in the ultrafiltration shell 21, and a sealing ring 22e is...

Embodiment 3

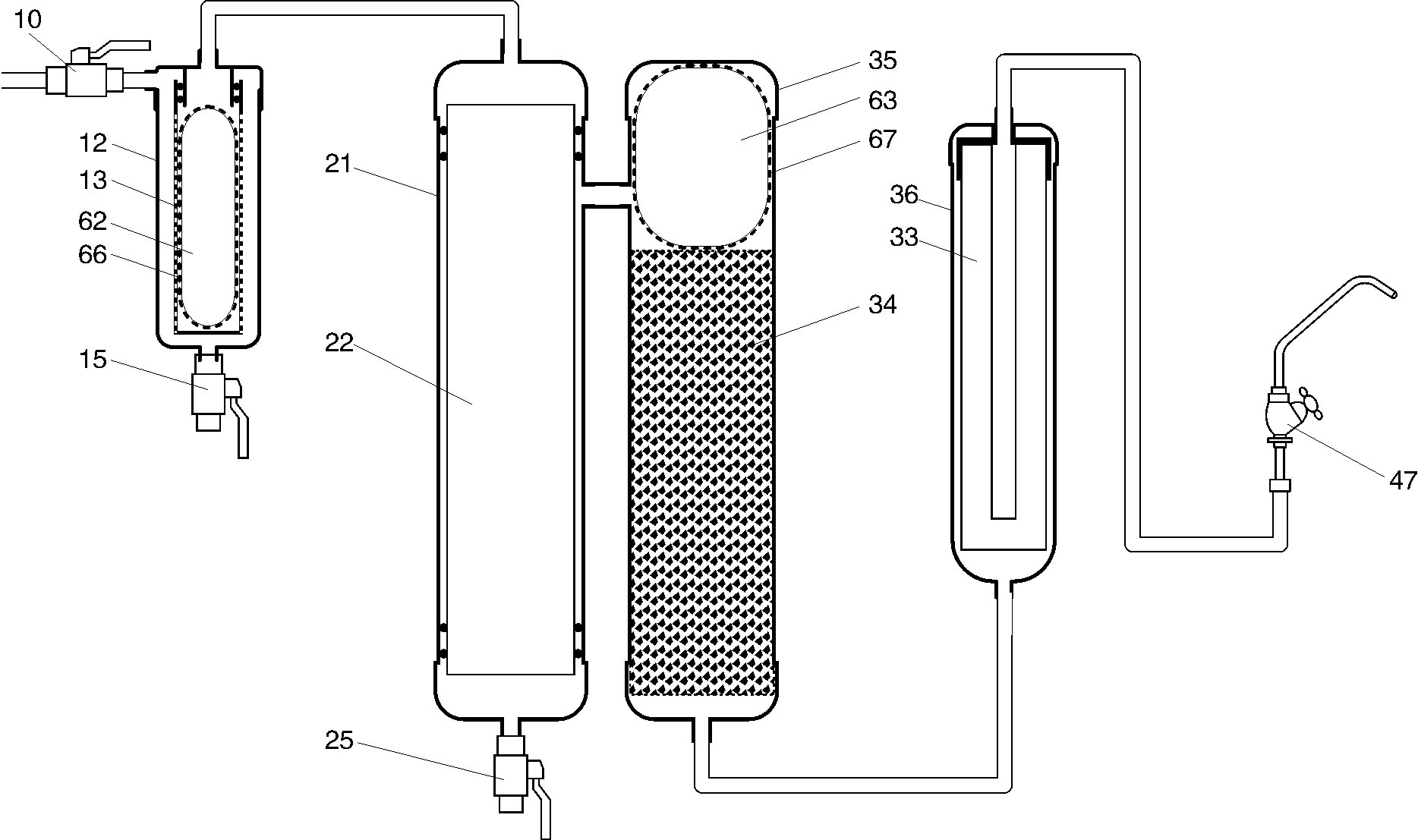

[0085] Embodiment 3 is an ultrafiltration water purifier with pre-protection and clean water backwashing functions, image 3 It is the structural representation of embodiment 3.

[0086] Structure of Embodiment 3

[0087] This embodiment is mainly composed of a coarse filter 12, a stainless steel filter screen 13, an air bag 62, an ultrafiltration filter element 22, an air bag 63, an activated carbon filter element 34, a fine filter element 33 and an ultrafiltration filter housing 21, a filter housing 35, and a filter housing 36; The coarse filter 12 is provided with a water inlet, a clean water port and a sewage outlet, and the water inlet is connected to the water inlet valve 10, and the clean water port is connected to the water inlet of the ultrafiltration filter element 22, and the sewage outlet is connected to the blowdown valve 15; the cylindrical stainless steel The filter screen 13 is installed in the coarse filter 12, and the central cavity of the stainless steel fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com