Deacidifying method for paper cultural relics

A technology of paper cultural relics and deacidification method, which is applied in the post-treatment of waste paper, etc., can solve the problems of books and newspapers that are difficult to preserve for a long time, accelerate paper acidification, air pollution, etc., achieve large-scale rapid deacidification treatment and avoid damage , Deacidification uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

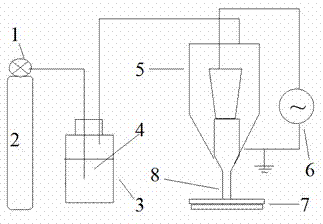

Image

Examples

Embodiment 1

[0020] 1) Spread the acidified paper cultural relics flat on the flat plate;

[0021] 2) Inject ammonia and Ca(OH) into the bubbler 2 , OH- and Ca 2+ The molar ratio of helium and nitrogen is 1:0.006, and a mixed gas of helium and nitrogen with a purity of 99.99% is passed into the bubbler, and the flow ratio of helium and nitrogen is He:N 2 =2:5, the total flow is 0.15 m 3 / h, the ion source reagent is transported to the plasma spray gun and ejected from the nozzle;

[0022] 3) Turn on the plasma excitation pulse power supply, adjust the voltage to 5kV, and the frequency to 2.0kHz to form a stable OH- and Ca 2+ The ion flame; start the spray gun scanning device, the high-energy OH- ions and Ca 2+ The ion jet is sprayed onto the surface of the flattened paper relics for deacidification for 1 minute.

[0023] The pH value of the deacidified paper was tested according to the standard procedure to quantify the deacidification effect. At the same time, the tensile index, soft...

Embodiment 2

[0026] 1) Spread the acidified paper cultural relics flat on the flat plate;

[0027] 2) Inject Ca(OH) into the bubbler 2 and KOH, OH- and Ca 2+ The molar ratio of helium and nitrogen is 1:0.002, and a mixed gas of helium and nitrogen with a purity of 99.99% is passed into the bubbler, and the flow ratio of helium and nitrogen is He:N 2 =5:5, the total flow is 0.10 m 3 / h, the ion source reagent is transported to the plasma spray gun and ejected from the nozzle;

[0028] 3) Turn on the plasma excitation pulse power supply, adjust the voltage to 10kV, and the frequency to 1.2kHz to form a stable OH- and Ca 2+ The ion flame; start the spray gun scanning device, the high-energy OH- ions and Ca 2+ The ion jet is sprayed onto the surface of the flattened paper relics for deacidification for 3 minutes.

[0029] The pH value of the deacidified paper was tested according to the standard procedure to quantify the deacidification effect. At the same time, the tensile index, softnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com