Split type gear

A split-type, gear technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of high maintenance cost, long maintenance time, and troublesome maintenance of gears, saving maintenance time, Cost saving and easy repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

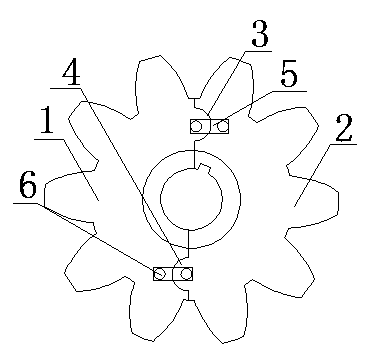

[0009] Such as figure 1 It is a structural schematic diagram of the present invention, a split gear, including left half wheel 1, right half wheel 2, C-shaped groove 3, C-shaped protrusion 4, fixing strip 5 and bolt 6, left half wheel 1 and right half wheel C-shaped grooves 3 and C-shaped protrusions 4 are provided on the wheels 2, and the C-shaped grooves 3 and C-shaped protrusions 4 are fixedly connected through the fixing strip 5, and the two ends of the fixing strip 5 are connected to the left half wheel 1 and the left half wheel through bolts 6. Right half wheel 2 is fixedly connected.

[0010] When in use, the left half wheel 1 and the right half wheel 2 are provided with a C-shaped groove 3 and a C-shaped protrusion 4, and the C-shaped groove 3 and the C-shaped protrusion 4 are fixedly connected by a fixing bar 5, and the fixing bar 5 and the The left half-wheel 1 and the right half-wheel 2 are fixedly connected by bolts 6 . This kind of split gear has a simple, compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com