Parameter-optimized metallurgical crane speed reducer gear service life evaluation method

A technology for optimizing parameters and life evaluation, applied in computer-aided design, geometric CAD, calculation, etc., can solve problems such as additional shock and noise, reduction of transmission accuracy and transmission efficiency, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in detail below in conjunction with the drawings and embodiments.

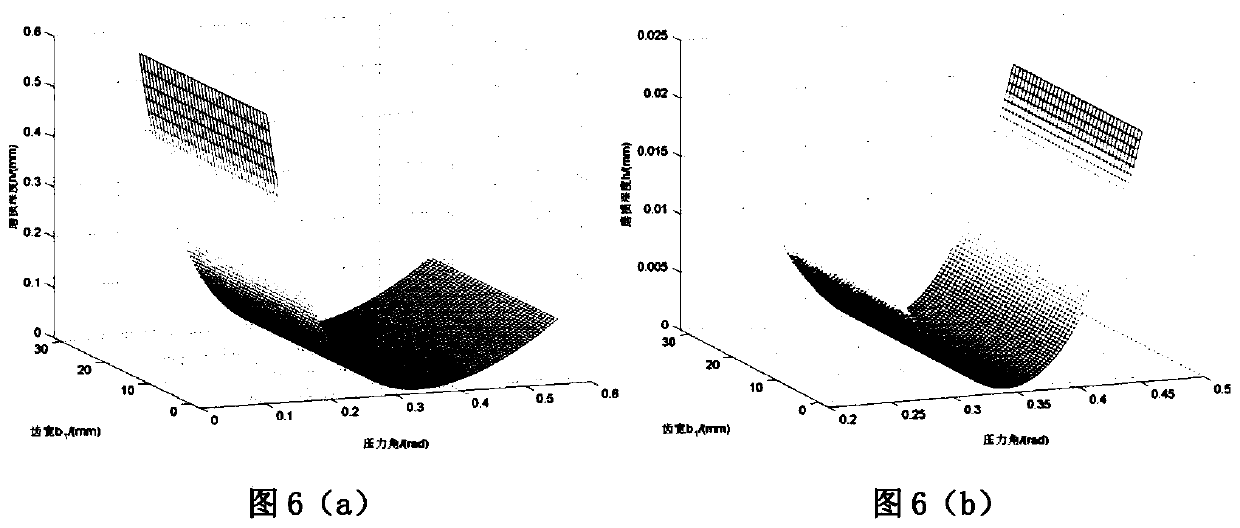

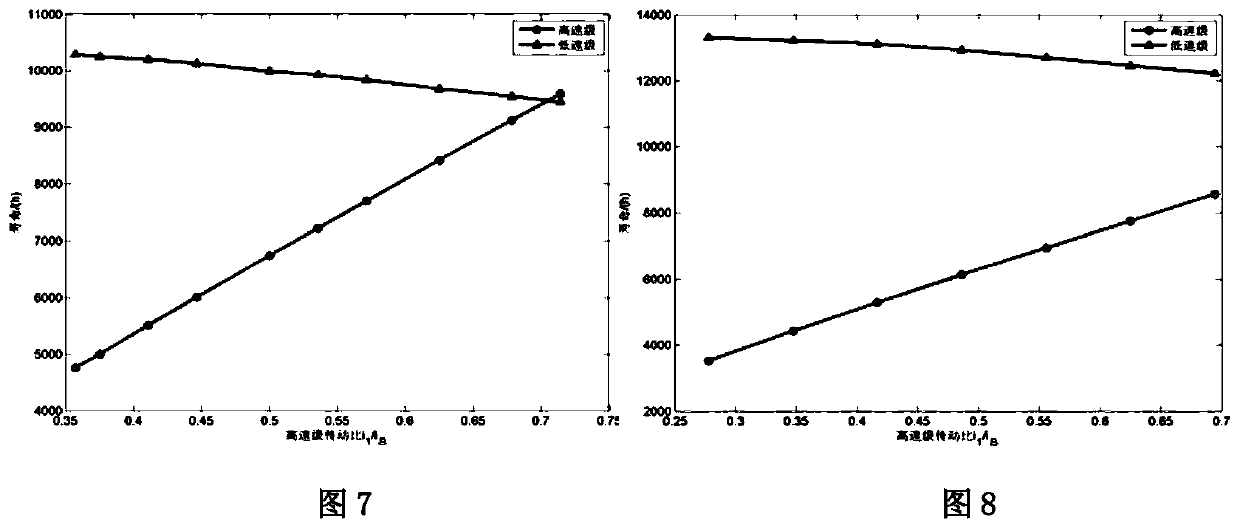

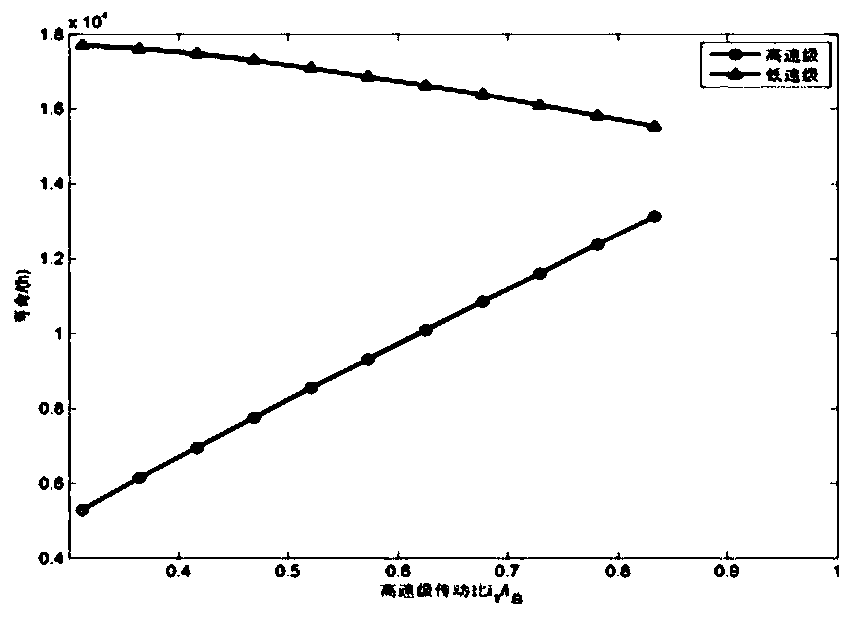

[0064] The present invention firstly constructs the tooth profile wear calculation formula based on the Archhard wear calculation model; secondly, for the two-stage transmission gears before and after the reducer, the total transmission ratio and the number of teeth of the driving gear of each stage are unchanged, and each gear is adjusted within a reasonable range of teeth. Step gear ratio, calculate the tooth profile wear and overall life in turn; then, for the same-level gear in the reducer, adjust the modulus and the number of teeth of the two wheels under the condition that the transmission center distance remains unchanged, calculate the tooth profile wear, and observe Its trend of change; finally introduce the displacement coefficient to reduce the wear of the tooth profile and extend the service life.

[0065] Preferably, the ZSC-400 vertical reducer is selecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com