Method for hierarchically diagnosing fault of rod-comprising oil pumping system based on indicator diagram

A technology of system fault and diagnosis method, applied in drill pipe, earthwork drilling, measurement, etc., can solve the problems of difficult to accurately determine boundary conditions and damping coefficients, large number of pumping units, difficult to accurately establish and solve mechanical models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

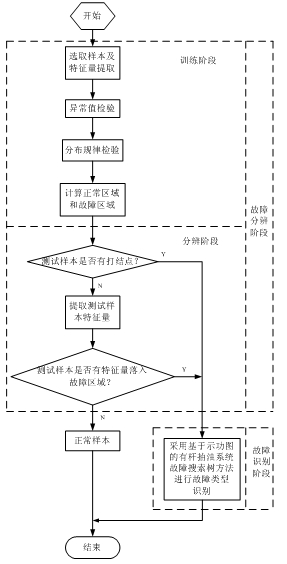

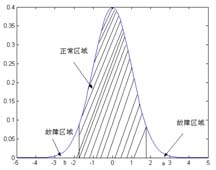

[0152] Aiming at the characteristics of the rod pumping system and the current problems of fault diagnosis, the present invention provides a fault diagnosis method of the rod pumping system based on the dynamometer diagram, which is divided into two stages of fault identification and fault identification. That is, first in the fault identification stage, the dynamometer diagrams are divided into fault and non-fault classes according to the statistical laws of normal samples; then, the statistical theory and search tree are combined to carry out detailed fault type identification for fault samples. It does not need to establish and solve the mechanical model of the rod pumping system, and there is no training set problem.

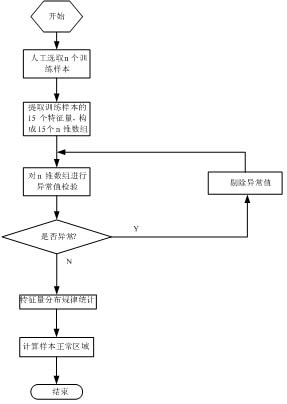

[0153] The provided fault identification method for the rod pumping system is divided into two stages of training and identification. In the training phase, after removing abnormal data by t test, the χ 2 The goodness-of-fit test determines the random distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com