Circulating water cooling system for cooling towers

A circulating water cooling and cooling tower technology, applied in the direction of water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of energy saving space, pipeline blockage, heat exchange efficiency decline, etc., to achieve Improve the efficiency of equipment use, reduce the number of maintenance, and improve the effect of heat exchange benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

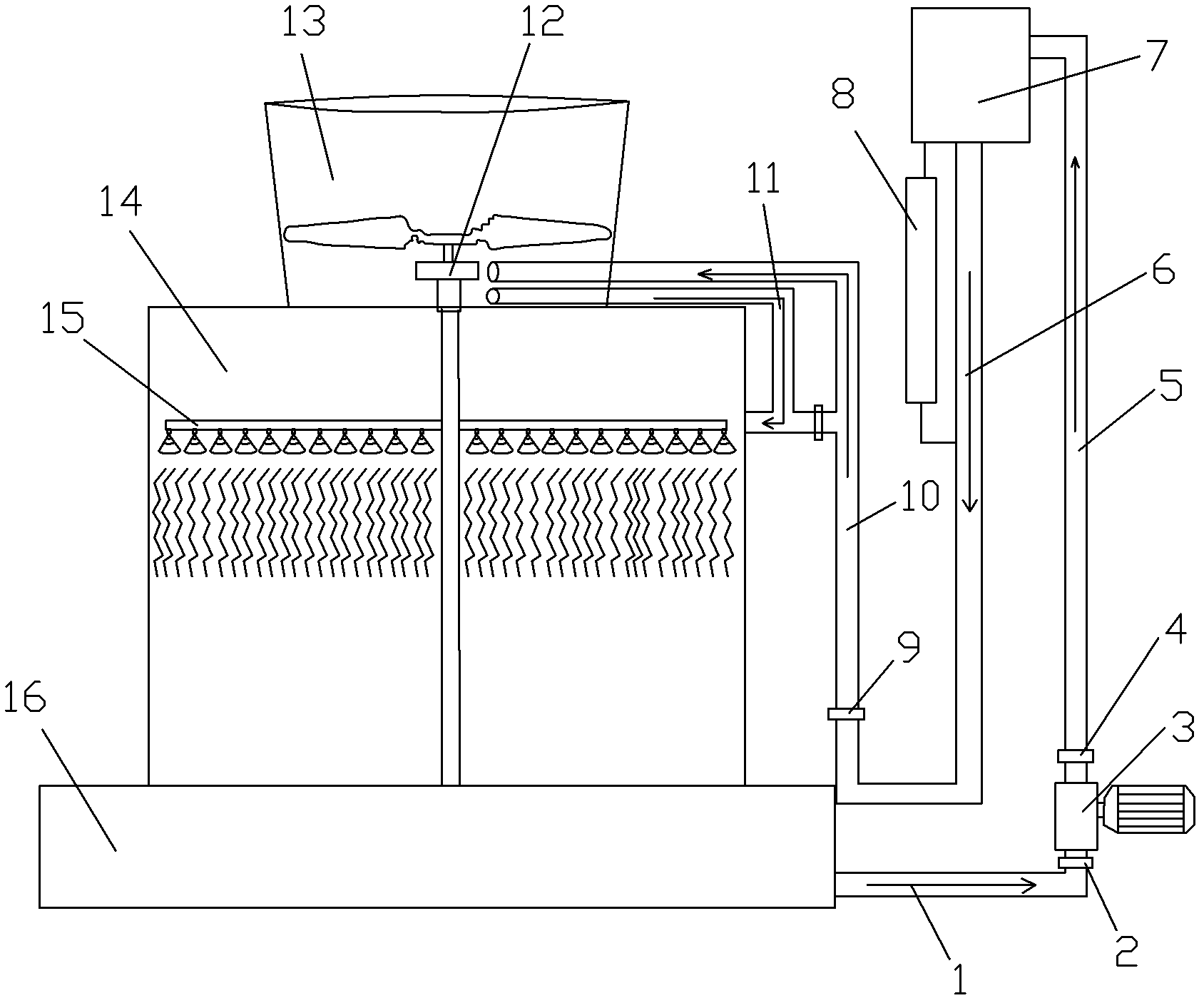

[0032] The present invention will be further described below in conjunction with the accompanying drawings:

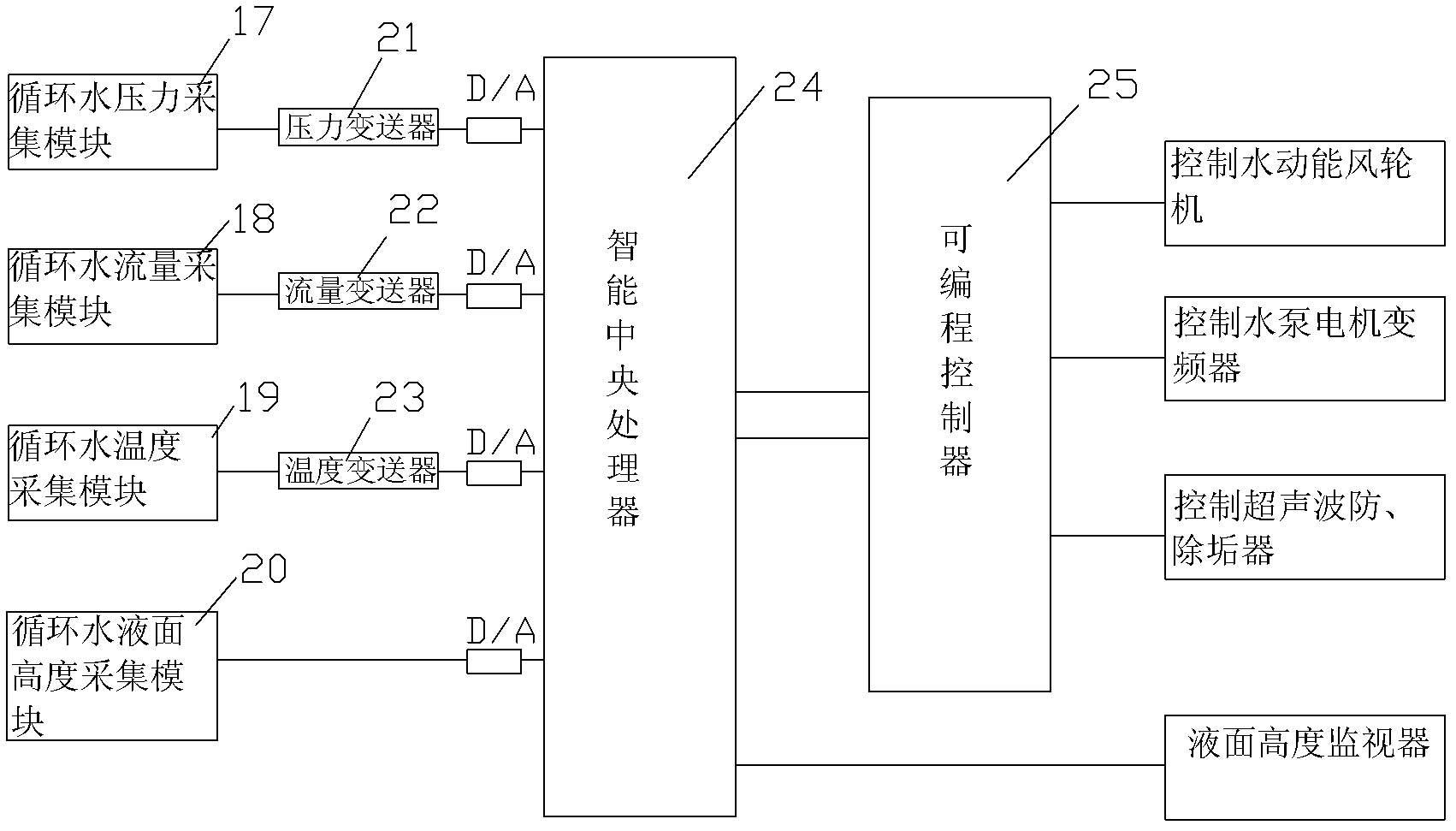

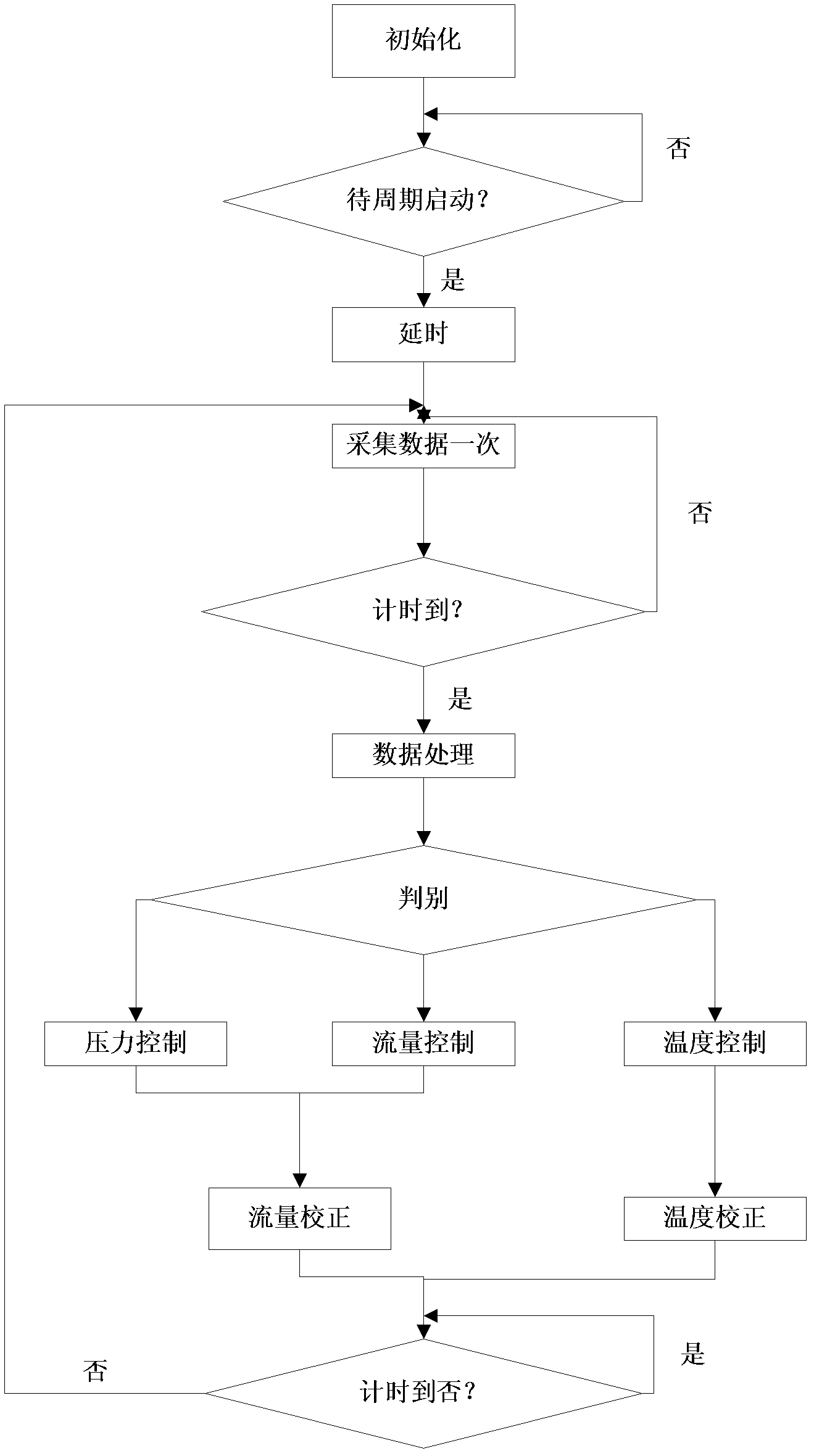

[0033] like figure 1 , figure 2 As shown, in the closed-loop circulating water cooling system of the cooling tower, the circulating water operating conditions are complex, the random disturbance is large, the large inertia and pure hysteresis are very serious, and its dynamic nonlinear characteristics are very obvious, mainly manifested in: pump flow constraints, Pipe diameter constraints, head constraints, pump constraints, etc., is a typical complex multi-variable control system. Due to the complexity of the control objects of the circulating system, the intelligent control system of the circulating water cooling system based on the neural network intelligent control is selected. The intelligent control system includes an intelligent central processing unit and a programmable controller. , The pressure transmitter is connected with the circulating water pressure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com