Sheet material feeding and conveying device

A technology for conveying devices and sheets, applied in storage devices, feeding devices, positioning devices, etc., can solve the problems of insurmountable slippage, high sheet loss, and inability to absorb sheets, etc., to achieve convenient and accurate lifting control transmission, and production. High efficiency and smooth feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

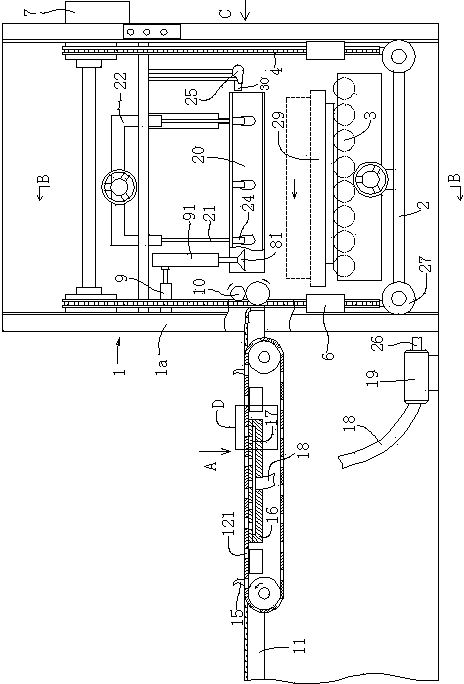

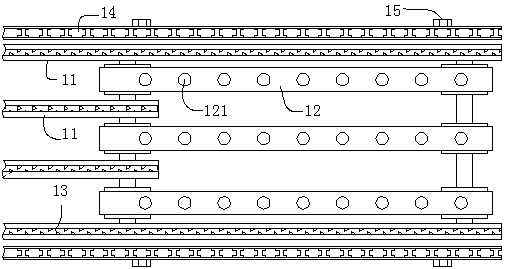

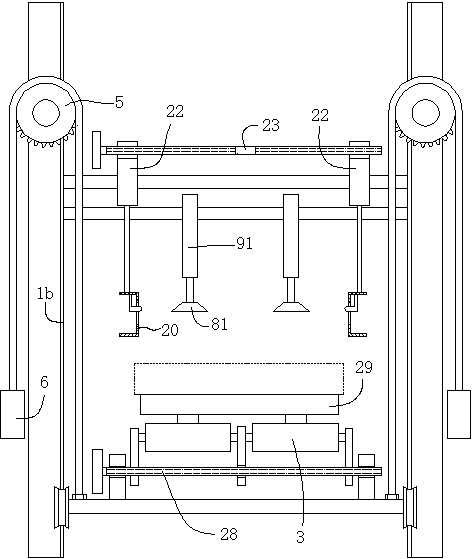

[0021] refer to Figure 1 to Figure 5 , a sheet material feeding and conveying device, including a frame 1 with columns 1a on both sides of the conveying production line, the lower part of the frame is provided with an elevator base 2, and a row is provided on the base for supporting stacked The transmission drum 3 of the thin plate is connected with the suspension chain 4 used to drive the machine base up and down on both sides of the front and rear sides of the machine base respectively. 6. The front and rear transmission sprockets located on the same side are driven by the same stepping motor 7 transmission mechanism, and the front and rear sides above the base are respectively provided with two lifting suction cups arranged in parallel and used to absorb thin plates. The lifting suction cup 81 is connected with the horizontal cylinder 9 connected on the frame to drive it to reciprocate forward and backward. A pair of horizontal rollers 10 are arranged on the front side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com