High-temperature acid chloride ion corrosion resistant steel plate and manufacturing method thereof

A technology of chloride ion corrosion and manufacturing method, applied in the field of marine steel plate, can solve the problems of high cost, low safety, increasing the risk of crude oil leakage and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

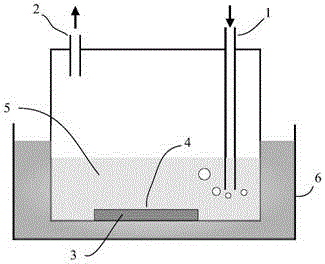

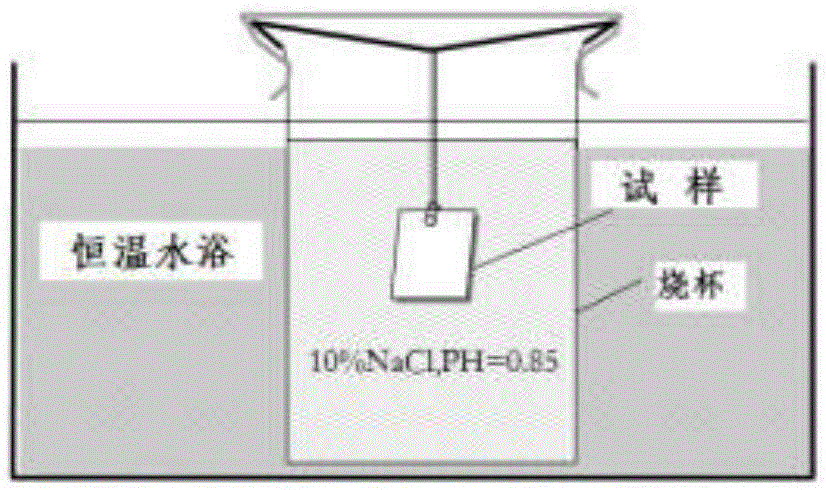

[0082]Corrosion experiments were carried out on the above five steels using the test method "Guidelines for the Inspection of Corrosion-Resistant Steels for Cargo Oil Tanks of Crude Oil Tankers" stipulated by China Classification Society. The sampling position is the surface of the steel plate, the sample size is (25±1)×(60±1)×(5±0.5) mm, and there are 5 parallel samples. All samples were ground to 600# with sandpaper, then cleaned with alcohol and acetone, dried, weighed, and measured the actual size of the samples. Hang the sample with a nylon thread on the figure 1 In the beaker shown, the mouth of the beaker is sealed with plastic wrap, and the composition of the corrosion solution is 10% NaCl aqueous solution, pH=0.85, calibrated with HCl, and the solution is replaced every 24 hours to reduce the change of pH value. The temperature of the solution was controlled by a constant temperature water bath to 30°C. The immersion period of the sample is 72h. After the test, the ...

Embodiment 2

[0088] Based on the test method in Example 1 above, the temperature of the test solution was controlled at 30°C, 35°C, 40°C, 45°C, and 50°C, respectively, to investigate the corrosion of five steels at different test temperatures. After the test was completed, the average corrosion rate (C.R.) of the steel was calculated according to the corrosion rate calculation formula in Example 1. The test results are shown in Table 4. It can be seen from the results that the corrosion rate of the comparative example steel increases greatly with the increase of the test temperature, while the corrosion rate of the inventive example changes little with the increase of the temperature, even when the test temperature is 50 ° C, only a small amount Pitting corrosion, exhibiting excellent high temperature corrosion resistance.

[0089] Table 4. Corrosion test data at different test temperatures

[0090]

Embodiment 3

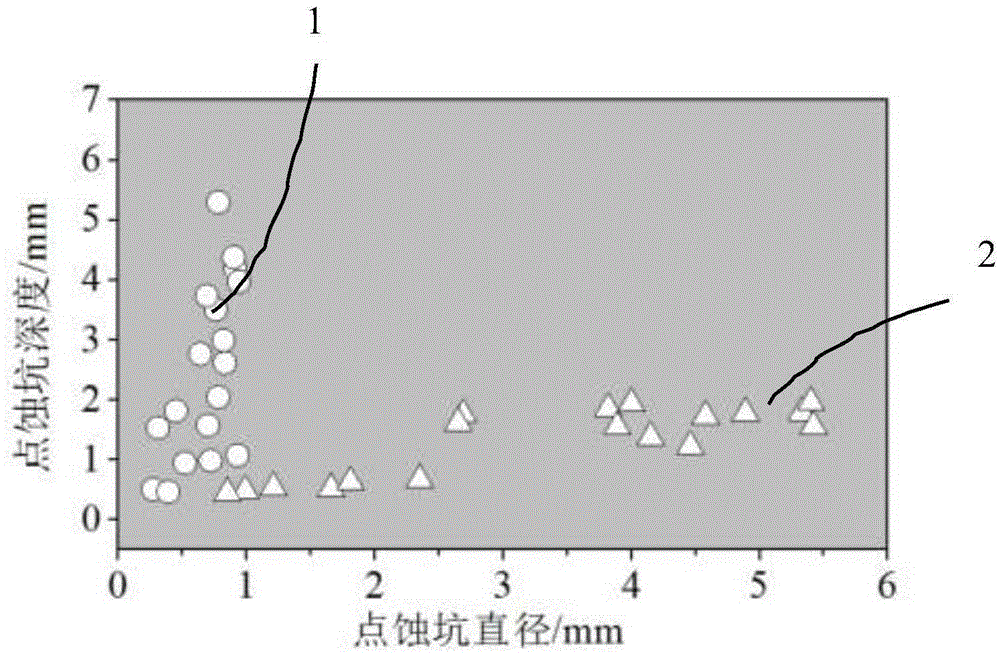

[0092] In order to simulate the steel surface in high concentration Cl - , Expansion behavior of localized corrosion in high acidity environment. For the steel grades of the above-mentioned comparative example and the invention example, a square sample of 50mm (length) × 25mm (width) × 8mm (thickness) was cut, and each surface of the sample was polished to 600#, and after cleaning with alcohol and acetone, the sample One of the 50mm×25mm surfaces is tested, and the other non-test surfaces are sealed with epoxy resin. During the test, the sample is in accordance with the attached figure 2 The method in the method is placed at the bottom of the reaction vessel, a certain amount of 10% NaCl aqueous solution is injected into the vessel 5, the pH value is 0.85, and HCl is used for proofreading, and the water temperature in the constant temperature water bath 6 is set to 40 ° C, and in the conduit In 1, the following two gases are mixed in 1:1 (in volume percentage): A gas: 8% O ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com