Ultra-high pressure etching foil and etching method thereof

A technology of corroding foil and ultra-high voltage, which is applied in the direction of electrolytic capacitors, coatings, capacitors, etc., and can solve the problems of poor uniformity of pores and uneven length of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

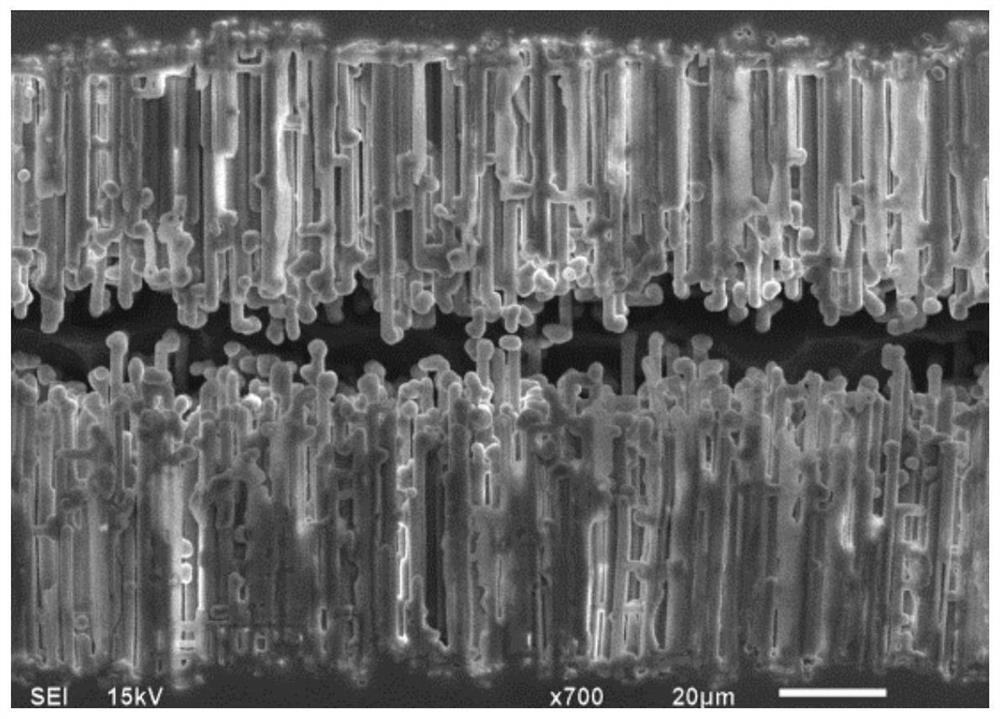

[0042] According to the embodiment provided by the present invention, the etching process of the ultra-high pressure etching foil includes:

[0043] 1) Pretreatment: soak the aluminum foil in sodium hydroxide solution first, then soak in a mixed solution of hydrochloric acid and sulfuric acid, and finally soak in phosphoric acid solution;

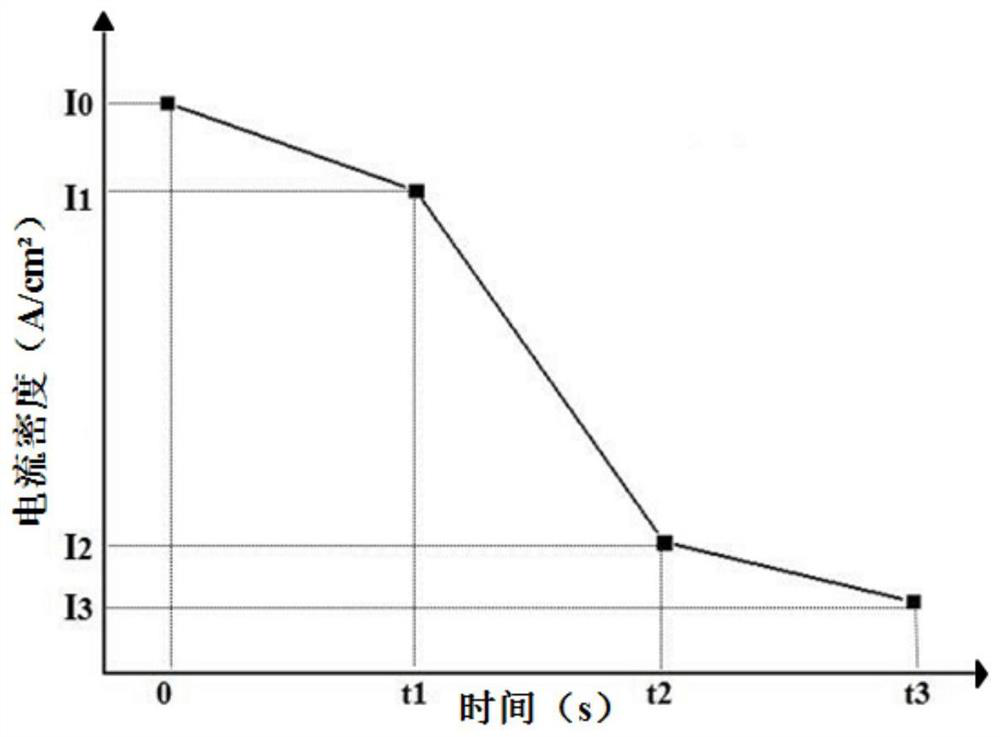

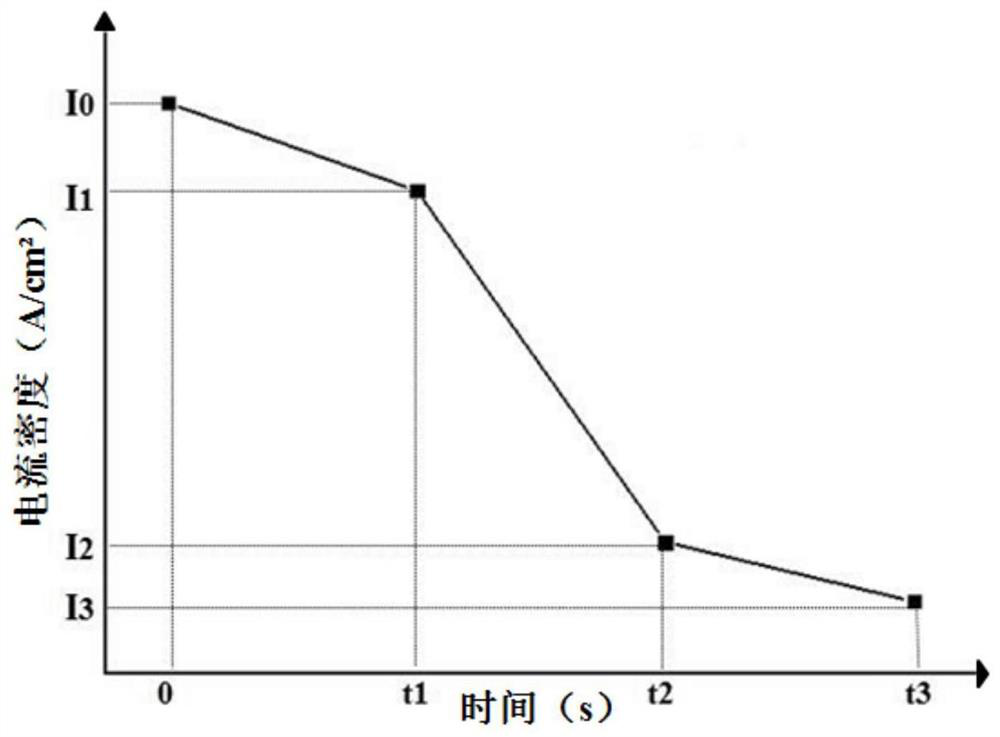

[0044] 2) First-level direct current porosity corrosion: place the pretreated aluminum foil in a mixed solution of hydrochloric acid and sulfuric acid added with aluminum ions to perform first-level porosity, and the power-on method adopts a three-stage combined attenuation current waveform;

[0045] 3) Secondary direct current porosity corrosion: put the aluminum foil corroded by the primary direct current porosity in a mixed solution of hydrochloric acid and sulfuric acid added with aluminum ions to perform secondary porosity, and the power-on method adopts a three-stage combined attenuation current waveform;

[0046] 4) Processing in the...

Embodiment 1

[0148] 1) Pretreatment: soak the aluminum foil in 1mol / L sodium hydroxide solution at 60°C for 30s, then place the aluminum foil in a mixed solution containing 2wt.% hydrochloric acid and 20wt.% sulfuric acid, soak it at 30°C for 30s, Finally, place the aluminum foil in a solution containing 0.1wt.% phosphoric acid and soak it at 50°C for 60s;

[0149] 2) First-level direct current porosity corrosion: place the pretreated aluminum foil in a mixed solution with an aluminum ion concentration of 0.5wt.%, a hydrochloric acid concentration of 8wt.% and a sulfuric acid concentration of 40wt.% for primary porosity; The temperature of hole corrosion is 65°C; the power-on method adopts three sections of combined attenuation current waveform: first power-on for 8s to change the current density from 0.9A / cm 2 Decay to 0.82A / cm 2 , and then energized for 11s to change the current density from 0.82A / cm 2 Attenuation to 0.2A / cm 2 , the last 8s to change the current density from 0.2A / cm ...

Embodiment 2

[0158] 1) Pretreatment: Soak the aluminum foil in 1mol / L sodium hydroxide solution at 45°C for 50s, then place the aluminum foil in a mixed solution containing 4wt.% hydrochloric acid and 30wt.% sulfuric acid, soak it at 50°C for 40s, Finally, place the aluminum foil in a solution containing 0.2wt.% phosphoric acid and soak it at 55°C for 60s;

[0159] 2) First-level DC porosity corrosion: place the pretreated aluminum foil in a mixed solution with an aluminum ion concentration of 0.8wt.%, a hydrochloric acid concentration of 10wt.% and a sulfuric acid concentration of 45wt.% for primary porosity; The temperature of hole corrosion is 65°C; the power-on method adopts three-stage combined decay current waveform: first power-on for 10s to change the current density from 0.87A / cm 2 Decay to 0.75A / cm 2 , and then energized for 13s to change the current density from 0.75A / cm 2 Decay to 0.15A / cm 2 , the last power-up 10s to change the current density from 0.15A / cm 2 Decay to 0.05...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com