Ultrahigh-pressure etched foil and etching method thereof

A technology of corroding foil and ultra-high pressure, applied in electrolytic coating, surface reaction electrolytic coating, anodic oxidation, etc., can solve the problems of poor uniformity of pores and uneven length of pores, and achieve accelerated dissolution, improved surface state, and increased capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

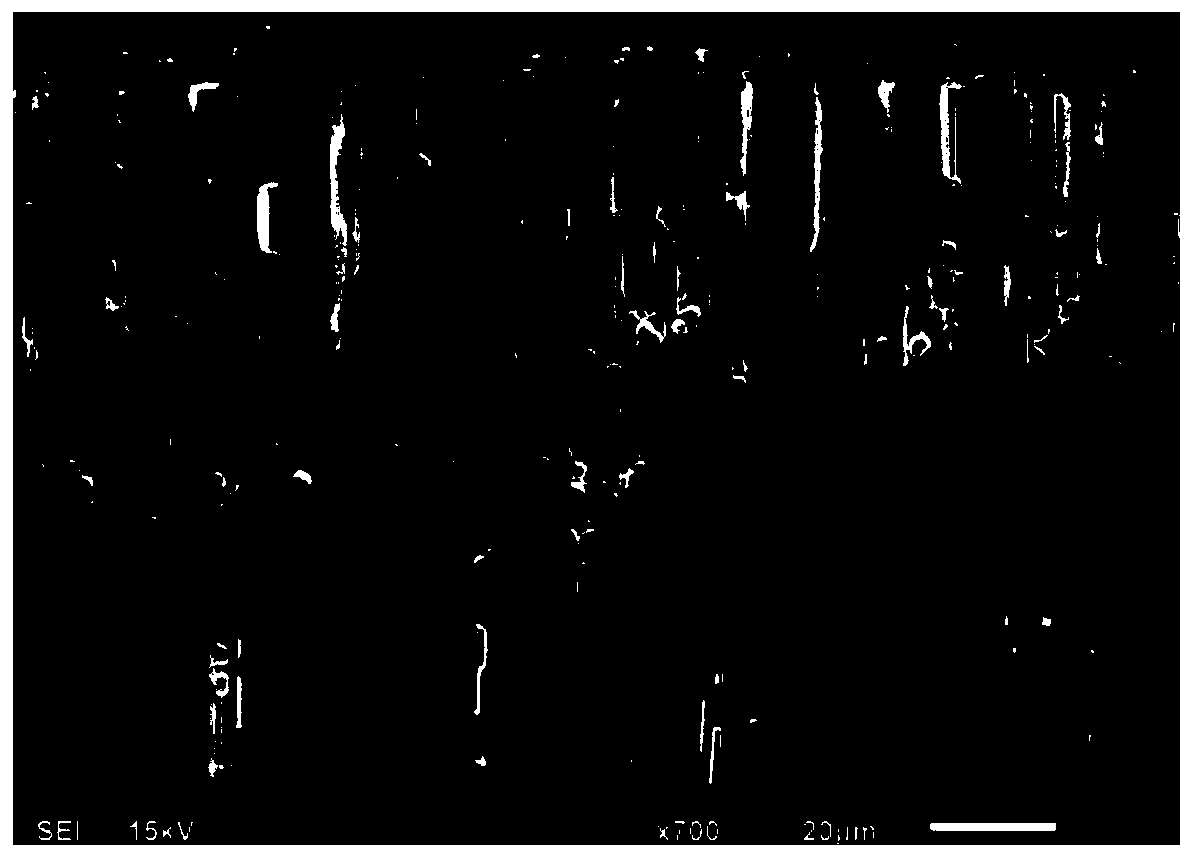

[0042] According to the embodiment provided by the present invention, the etching process of the ultra-high pressure etching foil includes:

[0043] 1) Pretreatment: soak the aluminum foil in sodium hydroxide solution first, then soak in a mixed solution of hydrochloric acid and sulfuric acid, and finally soak in phosphoric acid solution;

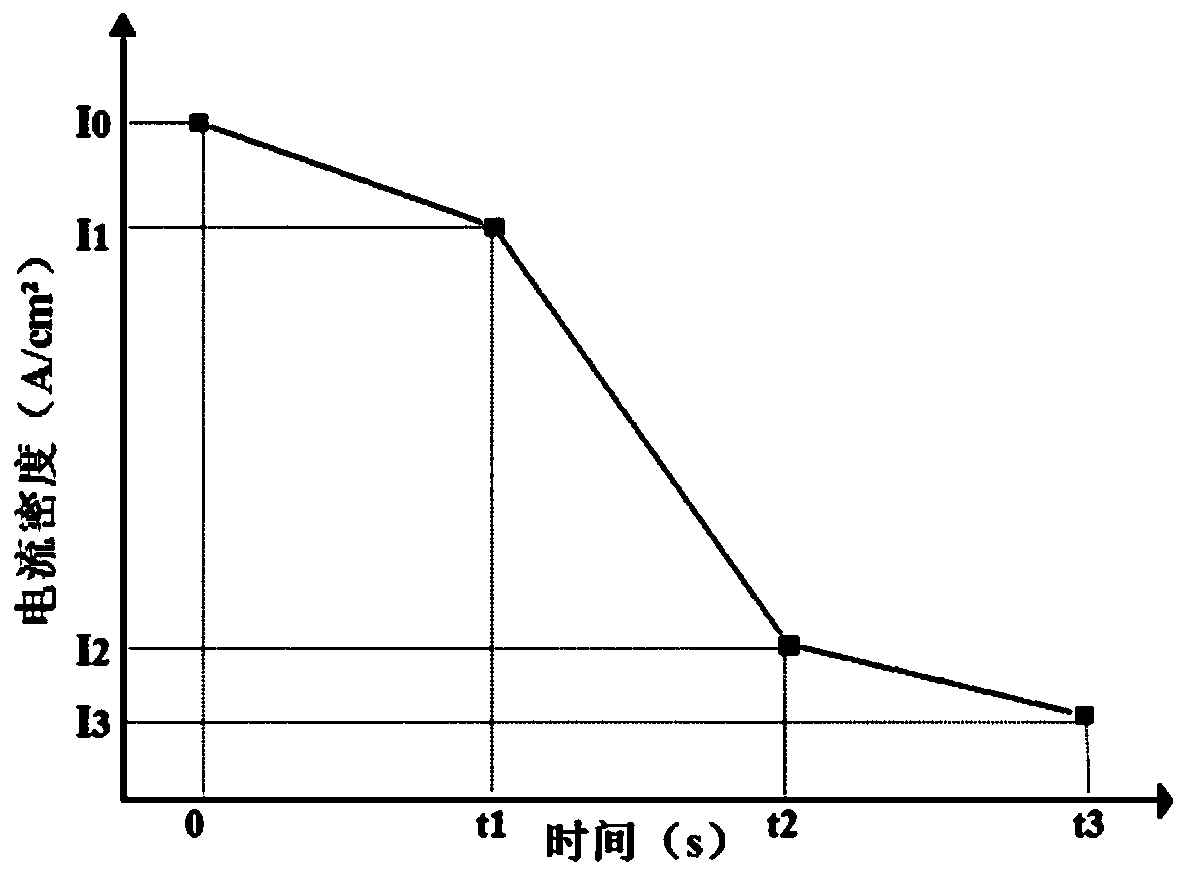

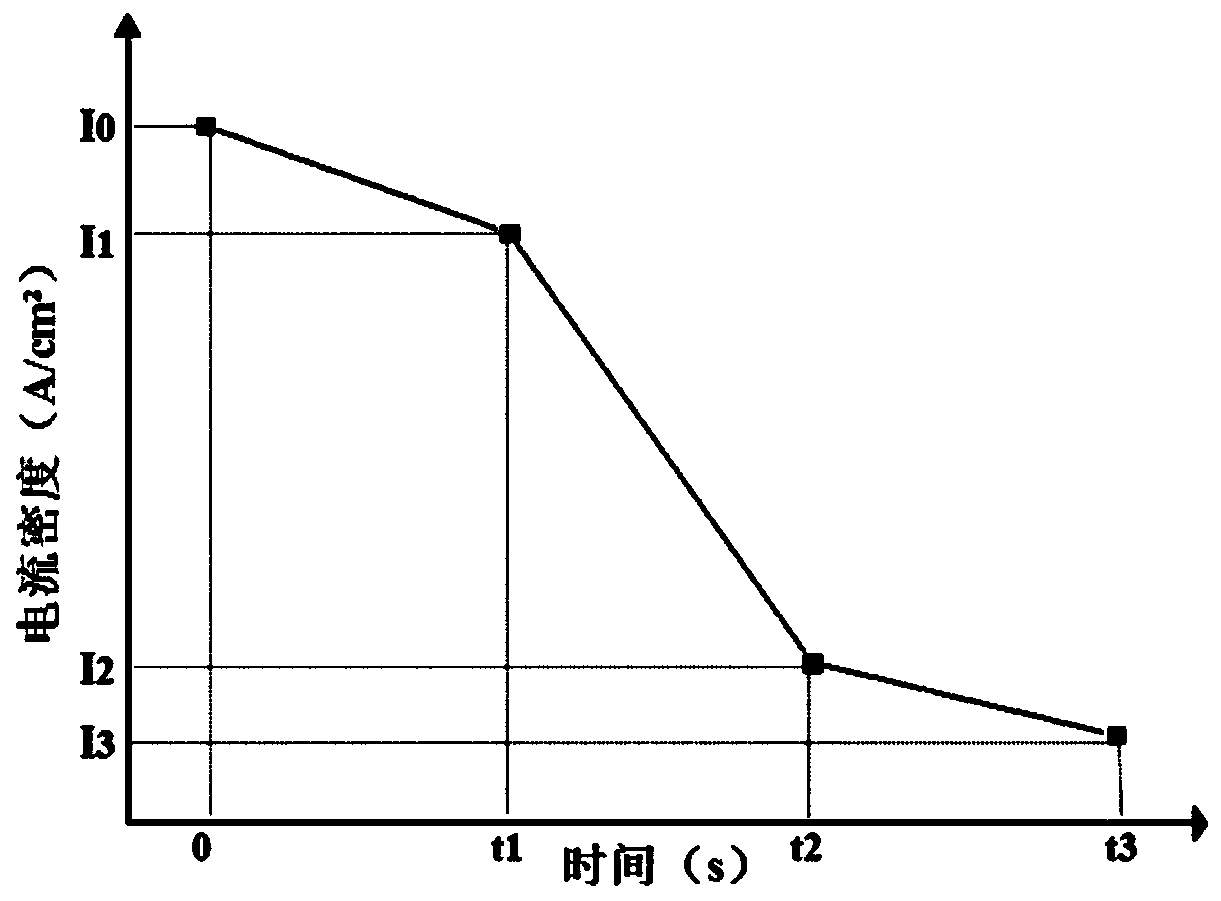

[0044] 2) First-level direct current porosity corrosion: place the pretreated aluminum foil in a mixed solution of hydrochloric acid and sulfuric acid added with aluminum ions to perform first-level porosity, and the power-on method adopts a three-stage combined attenuation current waveform;

[0045] 3) Secondary direct current porosity corrosion: put the aluminum foil corroded by the primary direct current porosity in a mixed solution of hydrochloric acid and sulfuric acid added with aluminum ions to perform secondary porosity, and the power-on method adopts a three-stage combined attenuation current waveform;

[0046] 4) Processing in the...

Embodiment 1

[0148] 1) Pretreatment: soak the aluminum foil in 1mol / L sodium hydroxide solution at 60°C for 30s, then place the aluminum foil in a mixed solution containing 2wt.% hydrochloric acid and 20wt.% sulfuric acid, soak it at 30°C for 30s, Finally, place the aluminum foil in a solution containing 0.1wt.% phosphoric acid and soak it at 50°C for 60s;

[0149] 2) First-level direct current porosity corrosion: place the pretreated aluminum foil in a mixed solution with an aluminum ion concentration of 0.5wt.%, a hydrochloric acid concentration of 8wt.% and a sulfuric acid concentration of 40wt.% for primary porosity; The temperature of hole corrosion is 65°C; the power-on method adopts three sections of combined attenuation current waveform: first power-on for 8s to change the current density from 0.9A / cm 2 Decay to 0.82A / cm 2 , and then energized for 11s to change the current density from 0.82A / cm 2 Attenuation to 0.2A / cm 2 , the last 8s to change the current density from 0.2A / cm ...

Embodiment 2

[0158] 1) Pretreatment: Soak the aluminum foil in 1mol / L sodium hydroxide solution at 45°C for 50s, then place the aluminum foil in a mixed solution containing 4wt.% hydrochloric acid and 30wt.% sulfuric acid, soak it at 50°C for 40s, Finally, place the aluminum foil in a solution containing 0.2wt.% phosphoric acid and soak it at 55°C for 60s;

[0159] 2) First-level DC porosity corrosion: place the pretreated aluminum foil in a mixed solution with an aluminum ion concentration of 0.8wt.%, a hydrochloric acid concentration of 10wt.% and a sulfuric acid concentration of 45wt.% for primary porosity; The temperature of hole corrosion is 65°C; the power-on method adopts three-stage combined decay current waveform: first power-on for 10s to change the current density from 0.87A / cm 2 Decay to 0.75A / cm 2 , and then energized for 13s to change the current density from 0.75A / cm 2 Decay to 0.15A / cm 2 , the last power-up 10s to change the current density from 0.15A / cm 2 Decay to 0.05...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com