Low temperature dyeing technique for wool

A low-temperature dyeing and process technology, applied in the field of wool low-temperature dyeing process, can solve the problems of incomplete dye absorption, increase dyeing cost, increase sewage discharge, etc., and achieve the effect of good color fixing effect, saving dyes and auxiliaries, and reducing sewage discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] 100% Australian wool, skein, dyed fruit green, weight 120kg.

[0024] 1. Dye:

[0025] Acid Bright Yellow 2G, the dosage is 0.14% of wool weight;

[0026] Acid lake blue A, dosage is 0.08% by weight of wool.

[0027] 2. Additives:

[0028] Sulfuric acid in an amount of 2% by weight of wool;

[0029] Yuanming powder, the dosage is 5% of wool weight;

[0030] Low-temperature dyeing accelerator SY-7, the dosage is 2% of wool weight.

[0031] 3. Dyeing equipment: skein dyeing machine S-300, horizontal (Qianzhou Yangjia Dyeing Equipment Factory, Wuxi).

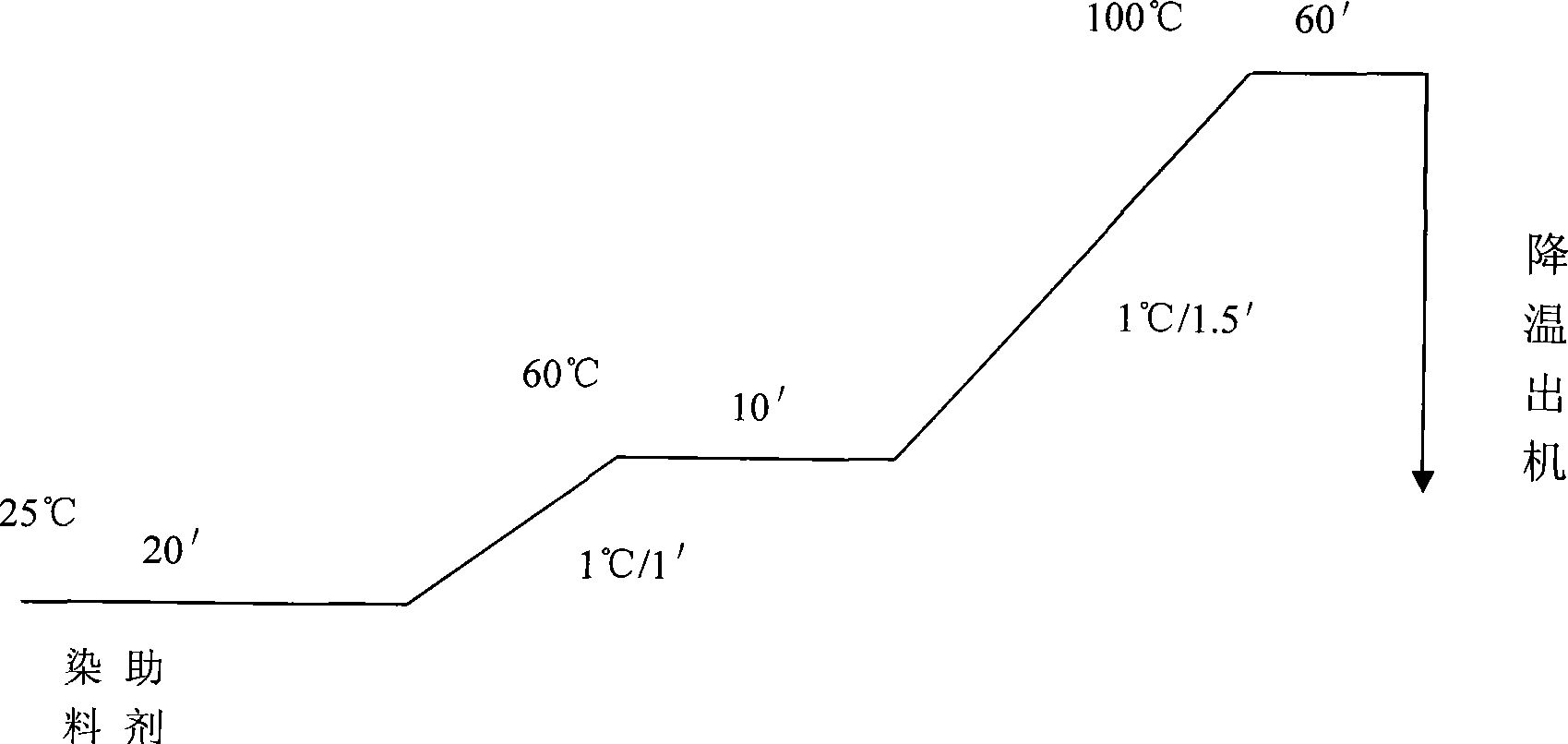

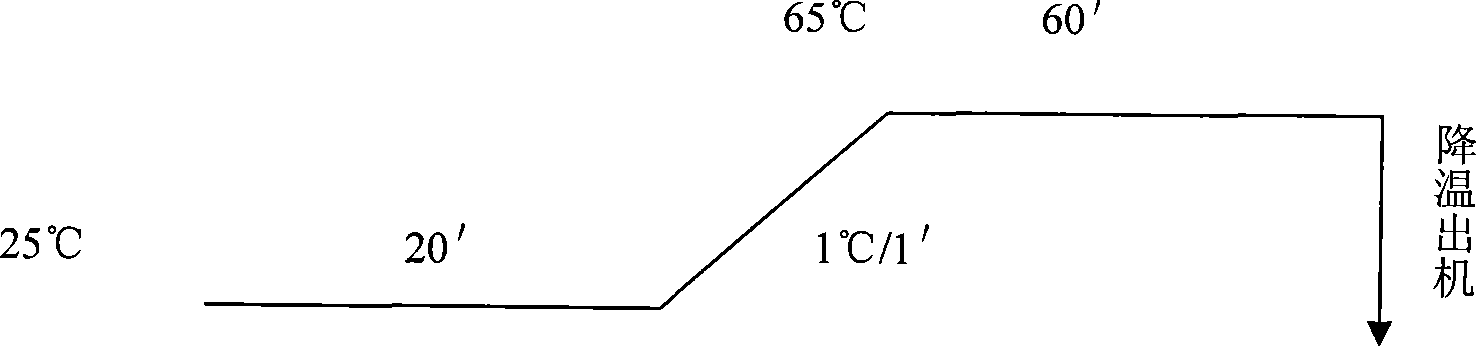

[0032] 4. Dyeing process:

[0033] The skeined Australian wool yarn is cleaned and put into the machine. After fully soaked, add sulfuric acid, sodium sulfate, and low-temperature dyeing accelerator SY-7 at 25°C, and run for 20 minutes; 1'Heat up to 65°C, keep the temperature constant for 30 minutes; add 1% sulfuric acid, keep the temperature constant for 30 minutes, cool down and leave the machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com