Red reactive dye for fur and preparation thereof

A reactive dye and red technology, applied in the field of wool reactive dye and its preparation, to achieve the effect of eliminating the generation of waste water and waste residue, excellent solubility, bright and beautiful color light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

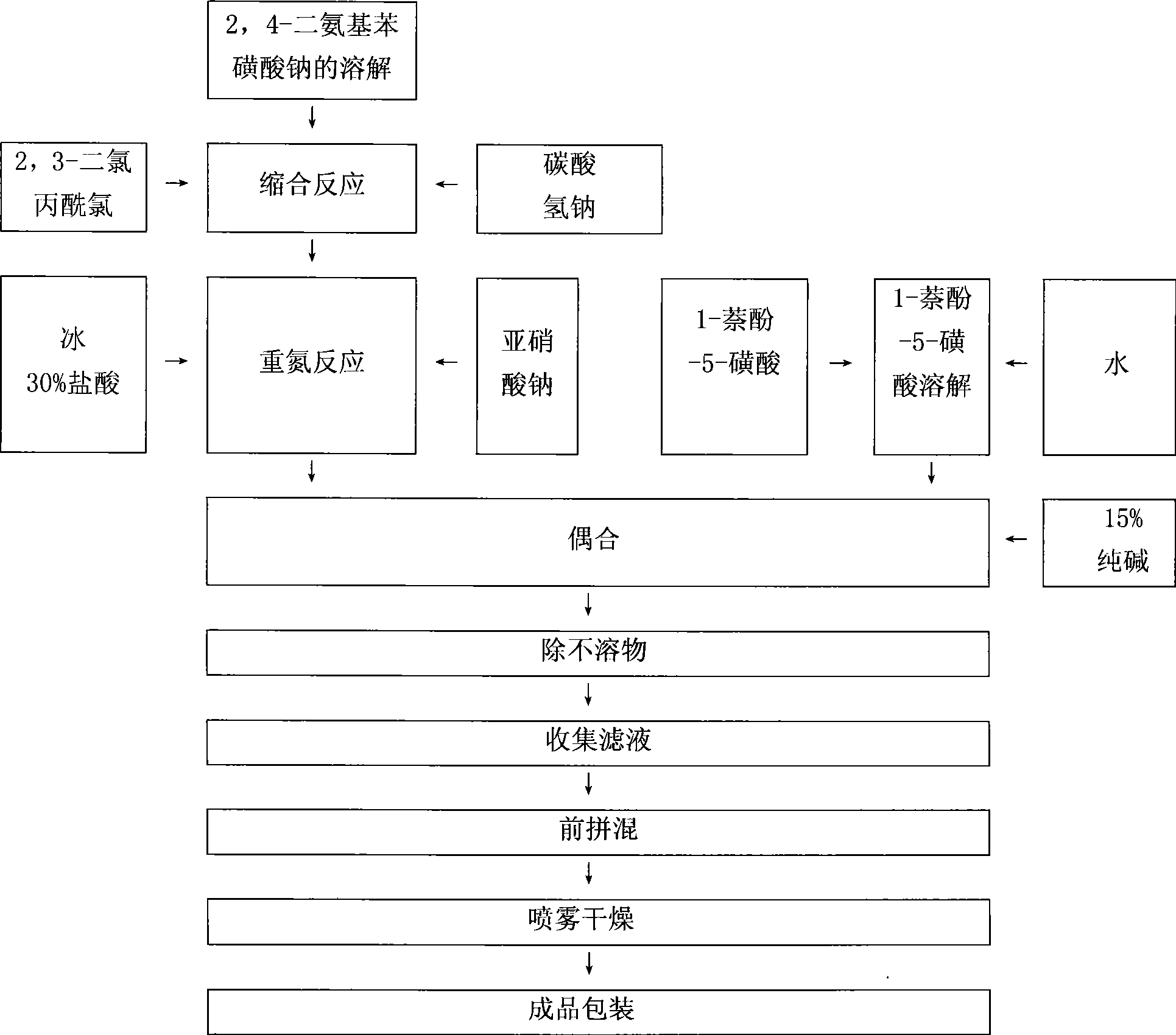

Method used

Image

Examples

Embodiment 1

[0032] 1. Ingredients list:

[0033] Raw material name Molecular weight Molecular ratio Percentage (Kg) Feeding amount (Kmol)

[0034] Sodium 2,4-diaminobenzenesulfonate 210 1 288.75 1.375

[0035] 2,3-Dichloropropionyl chloride 161.5 1.05 233.2 1.375

[0036] Sodium nitrite 69 1.02 96.77 1.375

[0037] Hydrochloric acid 36.5 2.5 125.47 1.375

[0038] 1-Naphthol-5-sulfonic acid 246 0.98 331.49 1.375

[0039] 2, dyestuff preparation technology of the present invention operates as follows:

[0040] a. Dissolution of sodium 2,4-diaminobenzenesulfonate

[0041] Put 2400 liters of bottom water in the reaction tank, add 288.75 kg of sodium 2,4-diaminobenzenesulfonate, heat up to 22°C, stir and dissolve, so that the materials are completely dissolved and clarified. Adjust the pH to 6-6.5 with dilute hydrochloric acid. The volume is 2625 liters, and C%=11 in the solution (referring to mass percent concentration, the same below).

[0042] b. Condensation reaction

[0043] Use ...

Embodiment 2

[0068] 1. Ingredients list:

[0069] Raw material name Molecular weight Molecular ratio Percentage (Kg) Feeding amount (Kmol)

[0070] Sodium 2,4-diaminobenzenesulfonate 210 1 288.75 1.375

[0071] 2,3-Dichloropropionyl chloride 161.5 1.05 233.2 1.375

[0072] Sodium nitrite 69 1.02 96.77 1.375

[0073] Hydrochloric acid 36.5 2.5 125.47 1.375

[0074] 1-Naphthol-5-sulfonic acid 246 0.98 331.49 1.375

[0075] 2, dyestuff preparation technology of the present invention operates as follows:

[0076] a. Dissolution of sodium 2,4-diaminobenzenesulfonate

[0077] Put 2400 liters of bottom water in the reaction tank, add 288.75 kg of sodium 2,4-diaminobenzenesulfonate, heat up to 22°C, stir and dissolve, so that the materials are completely dissolved and clarified. Adjust the pH to 6-6.5 with dilute hydrochloric acid. The volume is 2625 liters, and C%=11 in the solution (referring to mass percent concentration, the same below).

[0078] b. Condensation reaction

[0079] Use ...

Embodiment 3

[0099] 1. Ingredients list:

[0100] Raw material name Molecular weight Molecular ratio Percentage (Kg) Feeding amount (Kmol)

[0101] Sodium 2,4-diaminobenzenesulfonate 210 1 288.75 1.375

[0102] 2,3-Dichloropropionyl chloride 161.5 1.05 233.2 1.375

[0103] Sodium nitrite 69 1.02 96.77 1.375

[0104] Hydrochloric acid 36.5 2.5 125.47 1.375

[0105] 1-Naphthol-5-sulfonic acid 246 0.98 331.49 1.375

[0106] 2, dyestuff preparation technology of the present invention operates as follows:

[0107] a. Dissolution of sodium 2,4-diaminobenzenesulfonate

[0108] Put 2400 liters of bottom water in the reaction tank, add 288.75 kg of sodium 2,4-diaminobenzenesulfonate, heat up to 22°C, stir and dissolve, so that the materials are completely dissolved and clarified. Adjust the pH to 6-6.5 with dilute hydrochloric acid. The volume is 2625 liters, and C%=11 in the solution (referring to mass percent concentration, the same below).

[0109] b. Condensation reaction

[0110] Use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com