Method for dyeing mercerization baffeta with deep color on reactive dyes

A technology of reactive dyes and cotton fabrics, applied in the field of dyeing, can solve the problems of reactivity between dyes and cotton fibers, etc., and achieve the effects of reducing the amount of residual dyes, increasing the utilization rate, and improving the problem of deep color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

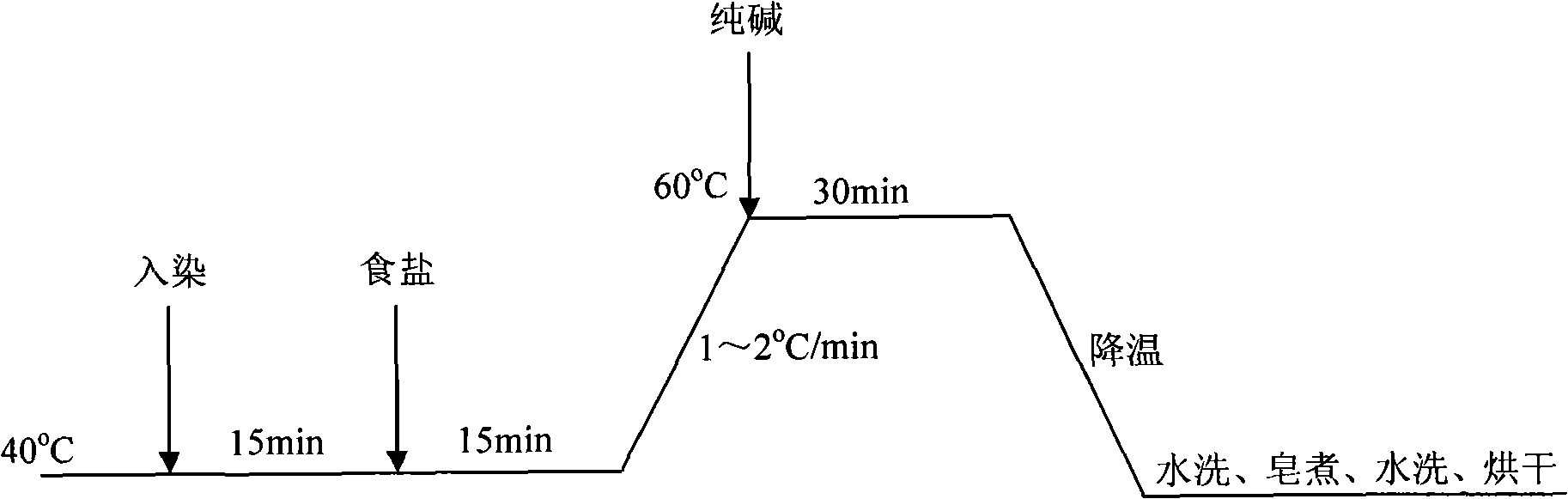

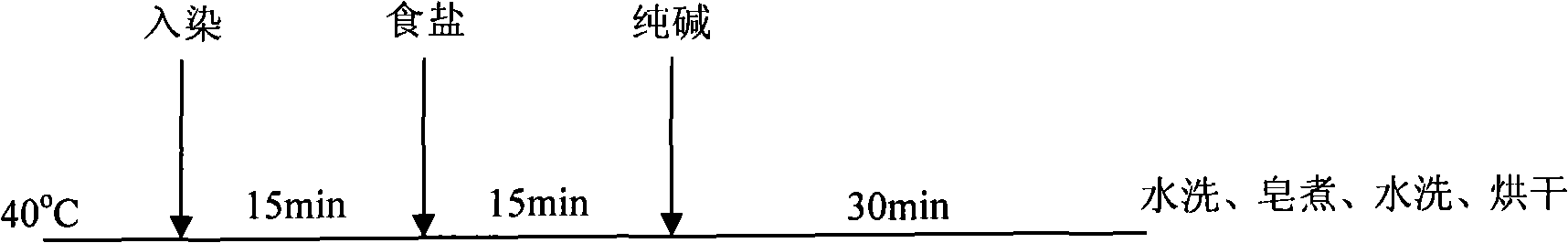

Embodiment 1

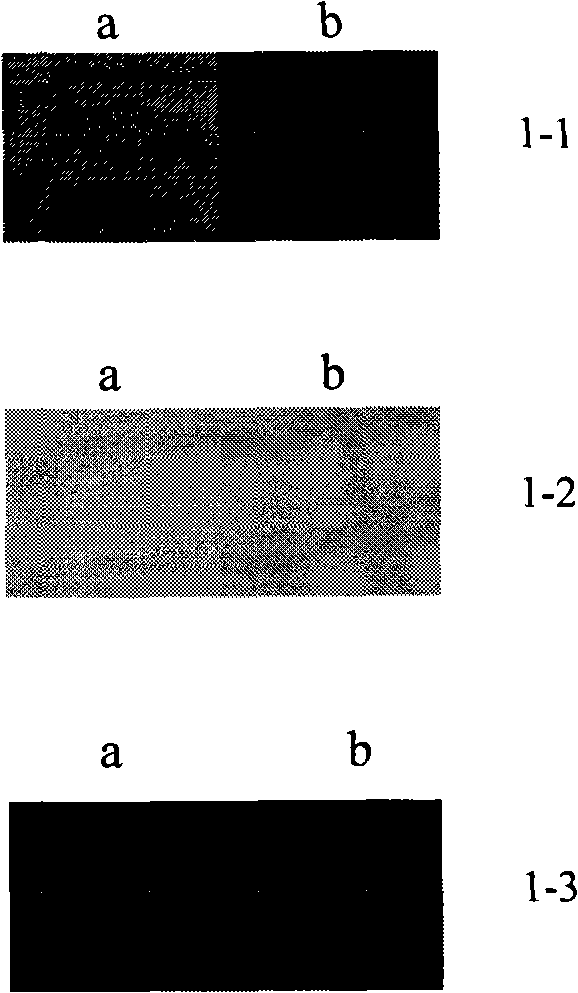

[0071] The mass ratio of diepoxide (dicyclopentadiene dioxide) to the glucose unit of cotton fiber is 1:50, and the mass concentration of weak base sodium hydroxide is 0.2%, wherein diepoxide and weak base The treatment is 40 ℃ processing 30min; the consumption of β-cyclodextrin is 3% (o.w.f), carries out the mercerizing treatment of cotton fabric 50s; At dye concentration 2% (o.w.f), liquor ratio 40: 1, respectively adopt technological curve ( figure 1 ), ( figure 2 ) for dyeing general (untreated) mercerized fabrics and mercerized cotton fabrics with cyclodextrin added after pretreatment. The dyes used were Huntsman Novacron Red FN-2BL, Huntsman Novacron Yellow FN-2R and Huntsman Novacron Blue FN-R. The results of relevant performance tests on the dyeing of dyes and dyed fabrics are as follows:

[0072] Table 1-1 Reactive dye exhaustion rate and fixation rate / %

[0073]

[0074] It can be seen from the above table that the exhaustion rate and color fix...

Embodiment 2

[0087] The mass ratio of the glucose unit adopting diepoxide (diepoxyhexanyl carboxylate) and cotton fiber is 1: 50, and the mass concentration of weak alkali sodium hydroxide is 0.2%, wherein, diepoxide and Weak base treatment is 35°C for 20min; the dosage of β-cyclodextrin is 3% (o.w.f), and the mercerizing treatment of cotton fabric is carried out for 60s; curve( figure 1 ), ( figure 2 ) for dyeing general (untreated) mercerized fabrics and mercerized cotton fabrics with cyclodextrin added after pretreatment. The dyes used were Huntsman Novacron Red FN-2BL, Huntsman Novacron Yellow FN-2R and Huntsman Novacron Blue FN-R. The results of relevant performance tests on dyeing and dyed fabrics are as follows:

[0088] Table 2-1 Reactive dye exhaustion rate and fixation rate / %

[0089]

[0090] It can be seen from the above table that the exhaustion rate and color fixation rate of the mercerized fabric are improved after treatment.

[0091] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com