A kind of polyimide carrier dyeing method

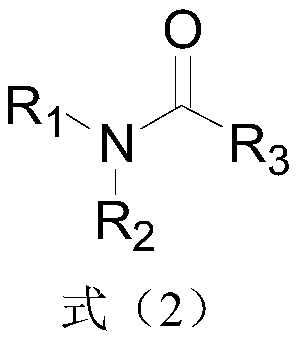

A polyimide and carrier dyeing technology, which is applied in the fields of textile printing and dyeing auxiliaries and textile dyeing and finishing processing, can solve the problems of non-conforming high-performance fibers and damage to fabric strength, and achieve deep fabric color, good fabric strength maintenance, and high-quality fabrics. The effect of large amount of dye

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

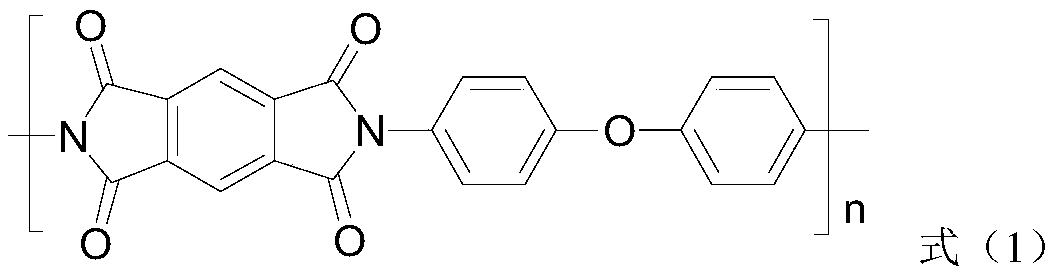

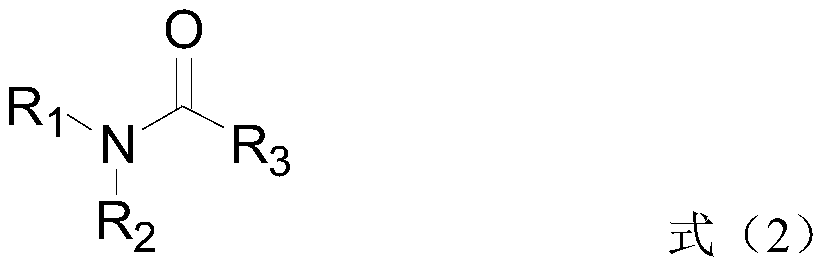

[0020] select R 1 is phenyl, R 2 is methyl, R 3 Substances that are hydrogen are used as carriers.

[0021] Get 2g polyimide knitted fabric, put into the solution that contains nonionic surfactant AEO-7 (2g / L) and degreasing agent CT-3 (1g / L), bath ratio is 30:1, at 95 Treat at ℃ for 30 minutes, fully wash with water and dry.

[0022] Put the polyimide fabric washed to remove impurities into the carrier dye solution containing 5% cationic red SD-GRL and 50g / L of the weight of the fabric, wherein the bath ratio of the dye solution to the fabric is 15:1, at 1.5 ° C / min speed up to 120°C for 40min.

[0023] After the dyeing is completed, put the fabric into the soaping solution containing 2g / L nonionic surfactant AEO-7 and 2g / L sodium carbonate, the bath ratio is 20:1, and fully treat the fabric at 85°C for 15min. Wash and tumble dry.

[0024] The color parameters and washing fastness of the dyed samples are shown in Table 1.

Embodiment 2

[0026] select R 1 is methyl, R 2 is methyl, R 3 Substances that are hydrogen are used as carriers.

[0027] Get 2g polyimide knitted fabric, put into the solution that contains nonionic surfactant AEO-7 (2g / L) and degreasing agent CT-3 (1g / L), bath ratio is 30:1, at 95 Treat at ℃ for 30 minutes, fully wash with water and dry.

[0028] Put the polyimide fabric washed to remove impurities into the carrier dye solution containing 5% cationic blue SD-GSL and 50g / L of the weight of the fabric, wherein the bath ratio of the dye solution to the fabric is 30:1, at 3°C / min speed to 130 ° C for 120 min.

[0029] After the dyeing is completed, put the fabric into the soaping solution containing 2g / L nonionic surfactant AEO-7 and 2g / L sodium carbonate, the bath ratio is 20:1, and fully treat the fabric at 85°C for 15min. Wash and tumble dry.

[0030] The color parameters and washing fastness of the dyed samples are shown in Table 1.

Embodiment 3

[0032] select R 1 is phenyl, R 2 is methyl, R 3 Substances for hydrogen and R 1 is methyl, R 2 is methyl, R 3 Substances that are hydrogen are used as carriers.

[0033] Get 2g polyimide knitted fabric, put into the solution that contains nonionic surfactant AEO-7 (2g / L) and degreasing agent CT-3 (1g / L), bath ratio is 30:1, at 85 Treat at ℃ for 30 minutes, fully wash with water and dry.

[0034] The polyimide fabric that washing removes impurity is put into the carrier that contains 5% cationic red SD-GRL to fabric weight and 5% cationic blue SD-GSL and 100g / L to fabric weight (two kinds of carriers each 50g / L), The liquor ratio of the dye liquor to the fabric is 20:1, and the temperature is raised to 120°C at a speed of 2°C / min and kept for 40 minutes.

[0035] After the dyeing is completed, put the fabric into the soaping solution containing 2g / L nonionic surfactant AEO-7 and 2g / L sodium carbonate, the bath ratio is 30:1, and fully treat the fabric at 85°C for 15min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com